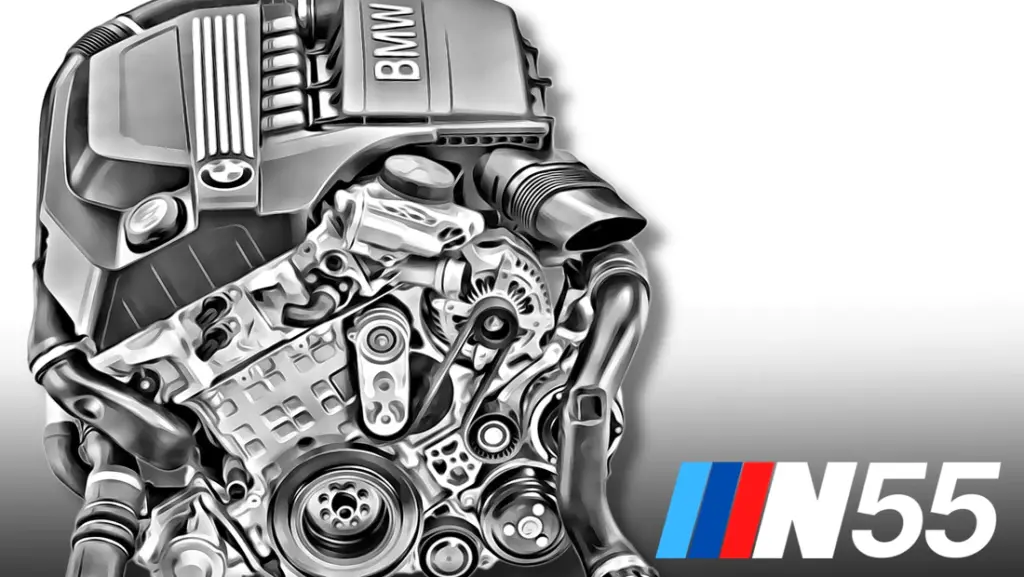

In the annals of automotive engineering, few powertrains have garnered as much acclaim as the BMW N55B30 engine. Introduced as a cornerstone of innovation, the N55 represents a pivotal shift in BMW’s approach to performance, efficiency, and reliability. This twin-scroll turbocharged wonder has not only set benchmarks within BMW’s lineup but has also left an indelible mark on the broader landscape of performance engines.

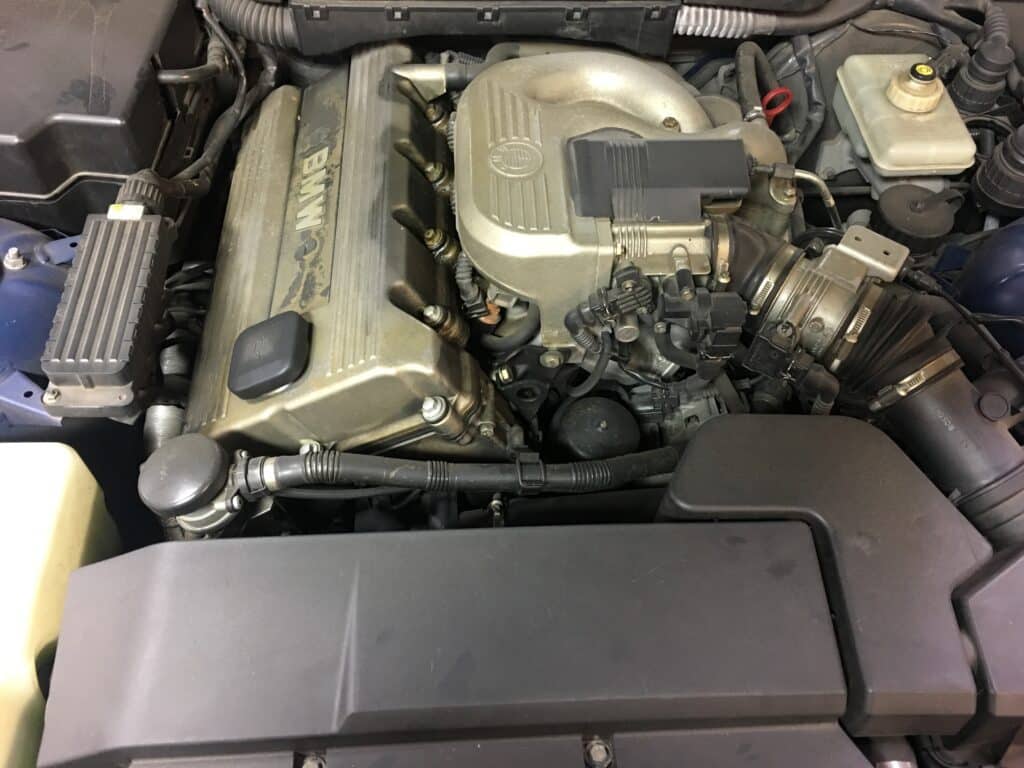

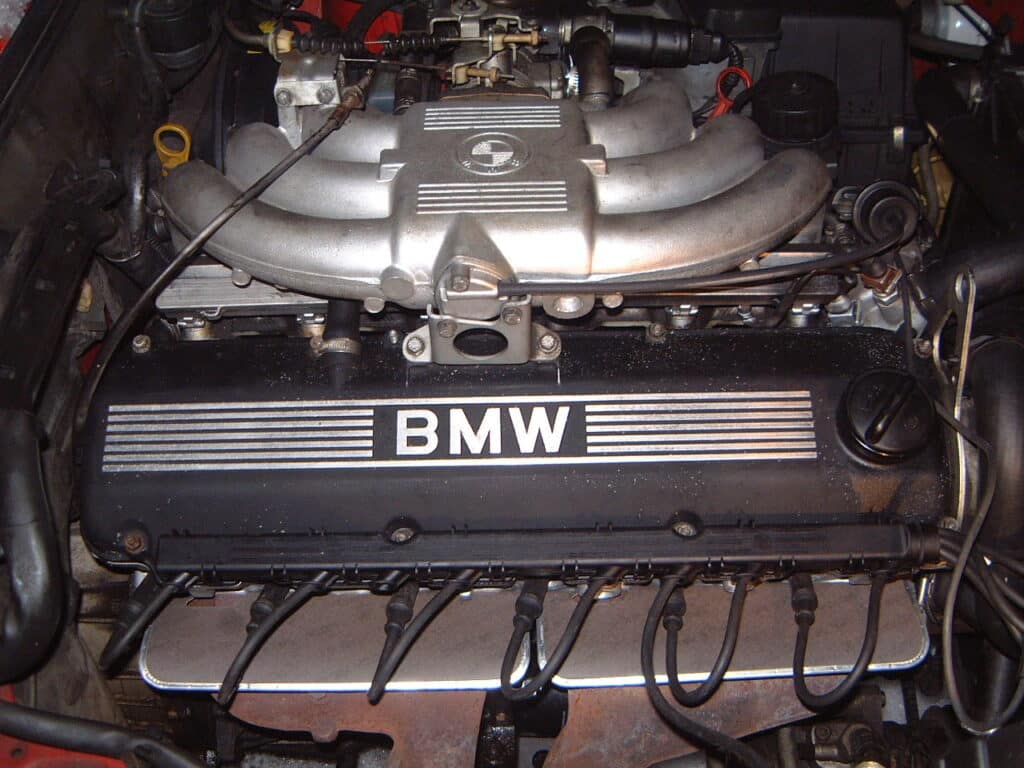

The BMW N55B30, commonly referred to as the N55, is a turbocharged straight-six engine that has become synonymous with delivering a blend of power and sophistication. First unveiled in 2009, it was a groundbreaking moment for BMW, marking the transition from the twin-turbo N54 to the more advanced, single twin-scroll turbocharger design.

With its 3.0-liter displacement, the N55 heralded new advancements such as BMW’s Valvetronic variable valve lift and Double-VANOS systems, which contributed to its smooth power delivery and responsive throttle.

The engine’s design was a masterclass in balancing performance with environmental considerations. It produced a substantial power output while achieving better fuel economy and lower emissions than its predecessor. Its harmony of direct fuel injection, precision-engineered components, and meticulous tuning created a symphony of performance that has thrilled drivers and impressed critics across the globe.

The Significance of the N55B30 in BMW’s Engine Lineup

The N55B30 was not just another engine in BMW’s storied history; it was a technological flagship, propelling a range of BMW’s mid-tier to high-end models to new heights. Vehicles bearing the iconic badges of the 3 Series, 5 Series, and even the sporty Z4 were endowed with the N55’s robust performance credentials.

The engine quickly gained a reputation for its flexibility, equally at home in the sedate cruise of luxury touring as it was on the demanding curves of a racetrack.

BMW’s implementation of the N55 across such a diverse lineup underscored its versatility and the company’s confidence in its reliability. It served as a bridge between the raw power of earlier BMW engines and the future direction of efficiency and performance, paving the way for its successors and the next generation of BMW’s turbocharged engines.

The N55 was more than an engine—it was a statement of BMW’s engineering prowess and a testament to their commitment to driving pleasure. Its legacy is not merely written in the spec sheets but is felt on the asphalt under the wheels of countless BMWs that still command the roads with authority.

BMW N55B30 Engine Specs

The BMW N55B30 engine is a marvel of modern engineering, a testament to BMW’s commitment to delivering high-performance, efficient engines. Below, we delve into the technical specifications that make the N55B30 a standout in BMW’s storied lineage of powertrains.

The N55B30 is characterized by its 3.0-liter displacement across six cylinders in an inline configuration. This direct-injection engine is turbocharged using a single twin-scroll turbocharger, a departure from the twin-turbo setup found in its predecessor.

The integration of BMW’s Valvetronic variable valve timing and lift system, along with Double-VANOS, provides continuous variable adjustment of valve timing on both intake and exhaust camshafts, which optimizes engine breathing and efficiency.

Cylinder Configuration and Displacement

| Specification | Detail |

|---|---|

| Configuration | Inline-6 |

| Displacement | 2979 cc (3.0 Liter) |

| Bore x Stroke | 84 mm x 89.6 mm |

| Compression Ratio | 10.2:1 |

This inline-6 layout is revered for its natural balance and smoothness, contributing to the engine’s renowned refinement and power delivery. The displacement of nearly three liters strikes a balance between torque-rich performance and reasonable fuel consumption.

Power Output and Performance Figures

| Specification | Detail |

|---|---|

| Power Output | 300-320 hp |

| Torque | 300-332 lb-ft |

| Turbocharger Type | Twin-scroll |

The N55B30’s power output ranges from 300 to 320 horsepower, with peak torque coming in at a robust 300 to 332 pound-feet, depending on the model and year. This broad range of torque is accessible from low revs, ensuring immediate response and brisk acceleration.

Comparison with Predecessor (N54) and Successor (B58)

When juxtaposed with the N54, the N55’s immediate predecessor, one can note several key enhancements. The N54 featured a twin-turbo setup which, while powerful, did not provide the same level of efficiency as the N55’s twin-scroll technology.

Moreover, the N55 introduced Valvetronic, which was absent in the N54, leading to improvements in fuel efficiency and emissions without sacrificing performance.

| Specification | N54 (Predecessor) | N55 (This Engine) | B58 (Successor) |

|---|---|---|---|

| Displacement | 2979 cc | 2979 cc | 2998 cc |

| Power Output | 306 hp | 300-320 hp | 335-382 hp |

| Torque | 295 lb-ft | 300-332 lb-ft | 369 lb-ft |

| Valvetronic | No | Yes | Yes |

| Turbocharger | Twin-turbo | Twin-scroll | Single twin-scroll |

Moving to the N55’s successor, the B58, there is an evolution in performance with an increase in power output and torque, thanks to further refinements in technology and engineering.

The B58 expanded upon the N55’s foundation with a slightly larger displacement, higher compression ratio, and an updated version of the twin-scroll turbocharger, along with other advancements that continued to push the boundaries of performance and efficiency.

Engine Design and Features

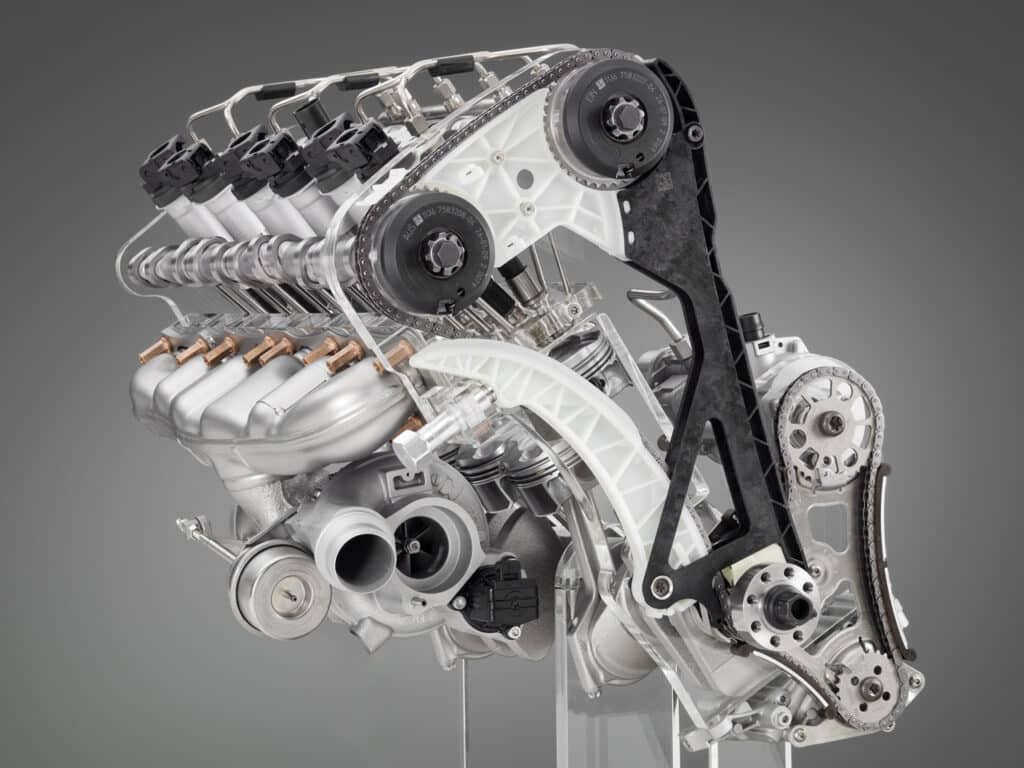

The BMW N55B30 engine is a paragon of the manufacturer’s innovative approach to performance engineering. A trio of sophisticated technologies—TwinPower Turbo, Valvetronic, and VANOS systems—form the heart of its design, each playing a crucial role in enhancing the engine’s capabilities.

At the forefront is BMW’s TwinPower Turbo technology, which, contrary to what the name might suggest, does not refer to two turbochargers but to a twin-scroll single turbocharger. This advanced design splits the exhaust streams from cylinders into two separate paths to the turbocharger, minimizing cross-flow and ensuring optimal use of exhaust pulse energy.

The result is a reduction in turbo lag, a significant improvement in throttle response, and a more linear power delivery across a wide RPM range.

Complementing the turbocharger is BMW’s Valvetronic system, a variable valve lift mechanism that allows the engine to “breathe” more freely. By adjusting the lift of the intake valves, Valvetronic eliminates the need for a traditional throttle mechanism, improving efficiency and response.

This works in tandem with the Double-VANOS (Variable Camshaft Timing), which precisely adjusts the timing of the intake and exhaust camshafts, optimizing engine performance at both high and low speeds and improving fuel consumption and emissions.

Direct fuel injection is another cornerstone of the N55 engine, squirting fuel directly into the combustion chamber at high pressure, ensuring a more precise and efficient burn. This technology supports a high compression ratio, contributing to improved power output and efficiency.

The N55’s design encapsulates BMW’s Efficiency Dynamics ethos—striving for the sweet spot where exhilarating performance meets conscientious fuel economy. This synergy of advanced technologies not only enhances the driving experience but also underpins BMW’s commitment to innovative and sustainable mobility solutions.

Engine Reliability and Longevity

The BMW N55B30 engine is renowned for its solid balance of performance and reliability. With proper maintenance, many N55 engines have surpassed the 200,000-mile mark without major issues, a testament to BMW’s engineering. However, as with any complex machinery, certain areas may require attention over time.

The N55 is generally regarded as reliable, particularly in comparison to its predecessor, the N54, which was known for its costly and frequent repairs. BMW addressed many of the N54’s shortcomings with the N55, resulting in fewer turbocharger and fuel system issues. The engine’s robust design and use of advanced materials have helped in achieving a good track record for reliability.

Known Issues and Model-Specific Concerns

Despite its reliability, the N55 has several known issues that owners should be aware of:

- High-Pressure Fuel Pump (HPFP) Failures: Early models of the N55 were prone to HPFP issues, which could lead to long crank times and reduced engine performance.

- Valve Cover and Gasket Leaks: With age, the valve cover and gasket may become brittle and crack, leading to oil leaks and potential ignition coil damage.

- Electric Water Pump Failures: The N55’s electric water pump can fail unexpectedly, leading to overheating and potential engine damage if not addressed promptly.

- Charge Pipe Cracking: The plastic charge pipe that comes stock on the N55 can crack under high boost, necessitating a replacement with a more durable aftermarket part.

- Carbon Build-up: Direct-injected engines like the N55 can suffer from carbon build-up on intake valves, which can lead to misfires and rough idling.

Preventive Maintenance Tips

To ensure longevity and prevent common issues, consider the following maintenance tips:

- Regular Oil Changes: Use high-quality synthetic oil and change it every 5,000 to 7,000 miles to ensure proper lubrication and cooling of engine components.

- Cooling System Maintenance: Replace the coolant every 30,000 miles and consider preemptive water pump and thermostat replacement after 60,000 miles.

- Inspect and Replace Ignition Components: Spark plugs and ignition coils should be inspected regularly and replaced as needed to prevent misfires and maintain optimal engine performance.

- Intake Valve Cleaning: Perform walnut blasting or chemical cleaning of the intake valves every 60,000 miles to remove carbon build-up.

- Charge Pipe Upgrade: Consider upgrading the charge pipe to a high-strength material to prevent cracking.

- Monitoring for Leaks: Regularly check for oil or coolant leaks and address them promptly to avoid further engine issues.

To ensure the N55 engine lasts for a long time, it’s important to follow a strict maintenance schedule and address any issues as they come up. Though the N55 is built to be strong, it’s a complex machine, and taking preventative measures is vital to avoid any setbacks that can arise from its advanced engineering. By doing so, drivers can enjoy a smooth and powerful ride that truly embodies the BMW experience.

Common Engine Problems

The BMW N55 engine, while highly regarded for its performance, is not immune to certain common issues. Understanding these problems and their symptoms can be critical for owners to maintain their vehicles effectively.

Turbocharger Failures and Symptoms

The N55 engine’s turbocharger is a key component of its power delivery system. Over time, however, it can suffer from wear and failure. Symptoms of turbocharger failure include a significant loss of power, a loud whining noise from the turbo, excessive exhaust smoke, and the Check Engine Light may come on. In some instances, the turbo may fail due to oil line blockages or wastegate issues, leading to a lack of boost pressure and reduced engine performance.

High-Pressure Fuel Pump Issues

Another known issue with the N55 is the failure of the high-pressure fuel pump (HPFP). Early symptoms include longer cranking times when starting the engine, a stuttering start, or a sudden loss of power while driving. The HPFP is critical for injecting fuel into the engine under high pressure, and when it malfunctions, it can lead to poor engine performance and even prevent the car from starting.

Water Pump and Thermostat Failures

The N55 utilizes an electric water pump which, unfortunately, is prone to failure. Typical signs of a failing water pump include overheating, coolant leaks, and the engine going into “limp mode” to prevent damage from excessive heat. The thermostat, which regulates the flow of coolant, can also fail, leading to similar overheating issues.

Vanos System Malfunctions

The VANOS system, responsible for varying valve timing, can also encounter problems. Symptoms of VANOS malfunction include rough idling, loss of power, poor fuel economy, and sometimes a rattling noise from the engine. VANOS solenoids and seals are often the culprits and may need cleaning or replacement to rectify the issue.

Carbon Build-up in Intake Valves

Due to the direct injection system of the N55, carbon deposits can accumulate on the intake valves over time. This can lead to a variety of engine issues such as misfires, rough idle, reduced throttle response, and a decrease in overall engine performance. Regular cleaning of the intake valves can prevent these deposits from becoming a significant problem.

Troubleshooting and Preventive Measures

To ensure the continued health of the N55 engine, it is vital to address these common problems proactively:

- Monitor Turbocharger Health: Regularly check for signs of turbo wear or failure, especially if experiencing power loss or unusual noises from the engine bay.

- HPFP Inspection: Be vigilant about any starting issues or performance drops, and have the HPFP inspected if any such symptoms arise.

- Water Pump and Thermostat Checks: Look out for overheating warnings, and consider replacing the water pump and thermostat as a preventive measure around the 60,000-mile mark.

- VANOS System Maintenance: Keep an ear out for any unusual noises and have the VANOS system checked if engine performance dips or idling becomes rough.

- Regular Cleaning of Intake Valves: Incorporate intake valve cleaning into your regular maintenance schedule to avoid carbon build-up.

Oil Capacity and Type

The lifeblood of any engine is its oil, serving as a crucial component for lubrication, cooling, and cleanliness. For the BMW N55B30 engine, the selection of the right oil type and adherence to oil change intervals is vital for ensuring the longevity and performance of the engine.

Recommended Oil Types for N55B30

BMW specifies that the N55 engine should use synthetic oil that meets its Longlife-01 certification. This oil is specifically formulated to comply with the high-performance demands of BMW engines.

It provides excellent wear protection, stable viscosity, and the ability to handle the high temperatures produced by the turbocharged engine. Popular choices among BMW owners and technicians include:

- BMW TwinPower Turbo 5W-30

- Mobil 1 0W-40

- Castrol EDGE 5W-30

These oils are designed to maintain their protective properties for extended periods, ensuring that the N55’s precision-engineered components are well-protected under all driving conditions.

Oil Capacity and Change Intervals

The N55B30 engine has an oil capacity of approximately 6.5 liters (6.9 quarts) when changing the oil and oil filter. BMW initially recommended oil change intervals of 15,000 miles under their free maintenance program.

However, many enthusiasts and experienced technicians suggest a more conservative interval of 7,500 to 10,000 miles, especially if the vehicle is driven in demanding conditions such as frequent short trips, extended idling, or high-performance driving.

Importance of Adhering to Oil Specifications

Using the correct oil and changing it at the recommended intervals cannot be overstated. The N55 engine’s turbocharger, VANOS system, and other high-tolerance components require the lubrication properties that only the recommended oils can provide.

Using lower-grade oils or extending change intervals beyond the advised range can lead to increased engine wear, reduced performance, and potentially severe engine damage.

The turbocharger, for instance, operates at extremely high speeds and temperatures, necessitating an oil that can withstand such conditions without breaking down.

Similarly, the precision of the VANOS system relies on the hydraulic properties of the oil to accurately adjust valve timing. Any degradation in oil quality can impede its function and affect engine performance.

Fuel Consumption

The fuel economy of a vehicle is a crucial aspect of its overall efficiency and cost of operation. For the BMW N55B30 engine, its fuel consumption rates are a balance between performance and efficiency, a testament to BMW’s engineering philosophy.

The N55B30 engine is rated at various fuel economy levels depending on the vehicle model and driving conditions. On average, owners can expect to see a range of around 20 miles per gallon (mpg) in the city and up to 30 mpg on the highway. These figures are influenced by the engine’s direct injection system and TwinPower Turbo technology, which work together to maximize fuel efficiency.

Several factors can affect the fuel consumption of the N55B30 engine:

- Driving Habits: Aggressive acceleration and high-speed driving significantly increase fuel consumption.

- Vehicle Load: Heavier loads require more power, thus more fuel.

- Maintenance: A well-maintained engine runs more efficiently. Worn spark plugs, dirty air filters, or underinflated tires can all lead to increased fuel use.

- Environmental Conditions: Cold weather can increase fuel consumption, as the engine takes longer to reach optimal operating temperature.

Tips for Improving Fuel Efficiency

Improving fuel efficiency not only saves money but also reduces the environmental impact of driving. Here are some tips for N55B30 owners:

- Drive Smoothly: Gradual acceleration and deceleration are more fuel-efficient than sudden speed changes.

- Maintain Optimal Speed: Higher speeds result in exponential fuel consumption increases. Driving at 55-65 mph is generally the most efficient range on highways.

- Regular Maintenance: Follow BMW’s recommended service intervals to ensure the engine and its components are functioning efficiently.

- Tire Maintenance: Keep tires properly inflated to the recommended pressure to reduce rolling resistance.

- Reduce Idle Times: Minimizing idle time prevents fuel wastage, as an idling engine still consumes fuel.

- Use Recommended Fuel: Stick to the grade of fuel recommended by BMW to ensure optimal engine performance and efficiency.

By following these tips, drivers can maximize their fuel economy, ensuring their N55B30 engine runs as efficiently as possible. These habits, combined with the engine’s advanced technology, can result in a noticeable reduction in fuel consumption over time.

Engine Firing Order

The firing order of an engine is fundamental to its design, influencing everything from its balance and smoothness to its sound and performance. For the BMW N55B30 engine, the firing order is a critical component that contributes to its renowned refinement and power delivery.

The N55B30 operates with a firing order of 1-5-3-6-2-4. This sequence is carefully engineered to balance the engine’s forces, ensuring smooth operation and minimizing vibration. A well-designed firing order is essential for the inline-6 configuration, as it impacts the harmonics and balance of the engine.

By firing the cylinders in this specific order, BMW has optimized the primary and secondary balance of the engine, which is inherent to the straight-six design.

The significance of the firing order comes into play when considering the engine’s kinematics. As pistons move up and down, they generate forces within the engine block. A firing order that is well-matched to the engine’s design helps to counteract these forces, leading to smoother operation and reduced strain on engine components.

Impact of Firing Order on Engine Performance

The firing order affects several aspects of engine performance:

- Vibration and Harshness: A proper firing order reduces vibrations, which in turn decreases noise and harshness, contributing to BMW’s signature driving comfort.

- Efficiency: Efficient combustion is partly achieved by the correct sequence of cylinder firing, which ensures that each combustion event occurs at the optimal moment for power delivery and fuel economy.

- Power Delivery: The smoothness of power delivery in the N55 engine can be attributed to its firing order, allowing for a linear and predictable increase in speed, enhancing the driving experience.

For enthusiasts and technicians, understanding the N55’s firing order can aid in troubleshooting and tuning. When performing engine work, such as replacing spark plugs or ignition coils, knowledge of the firing order is indispensable to ensure correct installation and engine function.

Spark Plugs and Gap

Spark plugs are a small but essential component of an engine’s ignition system, and for the BMW N55B30 engine, using the correct type and setting the proper gap is crucial for optimum performance.

Recommended Spark Plugs for N55B30

For the N55B30 engine, BMW recommends high-performance spark plugs that can withstand the heat and pressure of a turbocharged environment. These typically have a fine wire center electrode made of iridium or platinum to ensure durability and a consistent spark. Specific part numbers from reputable manufacturers include:

- NGK SILZKBR8D8S (NGK 97506)

- Bosch ZR5TPP33S

These spark plugs are designed to meet the stringent specifications required for the engine’s high performance and efficiency.

Spark Plug Gap Settings

The spark plug gap is the distance between the center electrode and the ground electrode. For the N55B30 engine, the recommended spark plug gap is typically set between 0.022 and 0.030 inches (0.56 mm to 0.76 mm). This gap size is critical as it affects the spark’s ability to ignite the air-fuel mixture in the combustion chamber effectively.

It is advisable to double-check the gap even on pre-gapped spark plugs, as they can shift during shipping. A spark plug gapping tool can be used to adjust the gap to the correct specification.

Replacement Intervals and Procedures

BMW suggests replacing the spark plugs on the N55B30 engine every 60,000 miles. However, for engines that are tuned or subject to high-performance use, the interval may be shorter. Here’s a brief overview of the replacement procedure:

- Engine Preparation: Ensure the engine is cool to avoid damaging the cylinder head threads.

- Accessing the Spark Plugs: Remove the engine cover and ignition coils to access the spark plugs.

- Removing Old Spark Plugs: Use a spark plug socket and extension to unscrew and remove the old spark plugs.

- Installing New Spark Plugs: Carefully thread the new spark plugs by hand to avoid cross-threading, then torque to BMW’s specification using a torque wrench.

Horsepower and Torque Curves

The horsepower and torque curves are crucial in understanding an engine’s character and performance envelope. The BMW N55B30 engine delivers a compelling narrative through its curves, revealing the essence of BMW’s engineering focus on responsiveness and elasticity.

Horsepower and Torque Over RPM Range

The N55 engine is known for its flat and generous torque curve, providing a peak torque of around 300 to 332 lb-ft available from as low as 1,200 rpm and sustained across a broad rev range. This is complemented by a horsepower curve that rises steadily, peaking between 5,800 and 6,500 rpm, depending on the model and tune, with outputs ranging from 300 to 320 hp.

The engine’s peaky horsepower and robust torque are achieved thanks to its advanced turbocharging technology and direct injection system, which work together to provide immediate throttle response and strong acceleration.

Real-World Performance Impact

What does this mean for the driver? In practical terms, the N55’s torque curve translates to brisk off-the-line starts and powerful mid-range acceleration, making overtaking maneuvers and highway merging effortless. The expansive torque also means that the engine is less stressed during casual driving, which can contribute to greater engine longevity and fuel efficiency.

Modifications and Enhancements

For those looking to extract more performance from the N55B30, there is healthy aftermarket support. Modifications like ECU tuning, cold air intakes, exhaust upgrades, and larger intercoolers can further improve the horsepower and torque curves.

Such enhancements can sharpen throttle response, increase peak power, and extend the torque plateau for an even more exhilarating driving experience.

However, it’s important to balance modifications with reliability considerations. Any changes to the engine’s performance characteristics should be complemented with supporting upgrades to the cooling system, fuel delivery, and ignition to maintain the engine’s integrity.

Timing Belt or Chain

In the realm of engine timing systems, the choice between a belt and a chain can significantly impact maintenance and reliability. The BMW N55B30 engine utilizes a timing chain, favored for its durability and longevity compared to a rubber belt.

Timing System Overview

The N55 engine’s timing chain is a critical component that synchronizes the crankshaft and camshaft rotations, ensuring that the engine’s valves open and close at the correct times during each cylinder’s intake and exhaust strokes.

This chain is made of metal, which is more robust and designed to last the life of the engine under normal operating conditions. It runs within the engine, lubricated by the engine oil, which helps to minimize wear and extend its service life.

Maintenance and Replacement Schedules

Unlike timing belts, which typically require replacement at regular intervals, timing chains in the N55 engine are generally maintenance-free. However, that does not mean they are immune to wear and potential failure.

BMW does not specify a replacement interval for the timing chain, but it is prudent for vehicle owners to be aware of the timing chain’s condition, especially as the vehicle accumulates high mileage or if the vehicle is driven in severe conditions.

Symptoms of Timing Chain Wear

There are several indicators that the timing chain or its related components may be wearing out:

- Rattling Noise: A common sign of a timing chain that has become loose or worn is a rattling noise from the engine, particularly when starting up or at low RPMs.

- Engine Misfires or Runs Poorly: If the timing chain has stretched, it can cause the engine’s timing to be out of synchronization, leading to misfires, poor running, and reduced performance.

- Metal Shavings in the Oil: During routine oil changes, the presence of fine metal shavings in the oil can be an indication of timing chain wear.

- Check Engine Light: Advanced wear or failure of the timing chain can result in the Check Engine light being triggered due to misreading by the engine’s sensors.

If any of these symptoms are present, it is advisable to have the engine checked by a professional mechanic as soon as possible. While the timing chain is designed to be durable, it is not infallible. Tensioners and guide rails, which are part of the timing chain system, can fail and lead to a timing chain malfunction, potentially causing severe engine damage.

Interference or Non-Interference

The design of an engine’s internal components, specifically the relationship between pistons and valves, determines whether it is an interference or non-interference engine. This distinction is crucial as it impacts what happens if the timing system fails.

An interference engine is designed in such a way that the valve’s path inside the cylinder head intersects with the piston’s path within the cylinder. While they never meet during normal operation due to precise timing, if the timing belt or chain fails, the pistons can collide with the valves, often causing catastrophic engine damage.

The BMW N55B30 engine is an interference engine. This design allows for higher compression ratios and a more compact engine size, contributing to the engine’s impressive power output and efficiency.

However, the interference nature of the N55 means that if the timing chain were to fail, the likelihood of significant engine damage is high, as the pistons and valves could come into contact.

To mitigate this risk, the N55 engine is equipped with a robust timing chain system designed to last the life of the engine. Nonetheless, owners should be attentive to the health of their timing chain and associated components, such as the tensioners and guide rails. Any signs of wear or failure should be addressed immediately to prevent potential engine damage.

In the event of timing system failure, due to the interference design, it is generally recommended that the engine be inspected by professionals who can assess the extent of damage and perform the necessary repairs or engine rebuild.

Engine Coolant

The engine coolant is a vital fluid that manages the temperature of your engine, preventing it from overheating. Choosing the right coolant and maintaining the cooling system are essential for the health of your BMW N55B30 engine.

Coolant Types and Specifications

BMW specifies a particular type of antifreeze for use in the N55B30 engine. The recommended coolant is a nitrite-free, phosphate-free, and amine-free formula that is typically blue or green in color.

BMW’s own branded antifreeze or equivalent coolants that meet BMW’s LL-01 or LL-04 specifications should be used to ensure proper corrosion protection and cooling performance.

Cooling System Maintenance

Regular maintenance of the cooling system is crucial for the longevity of the engine. The coolant should be replaced every 60,000 miles or every four years, whichever comes first.

This interval ensures that the coolant’s anti-corrosive properties remain effective and that the system is free of contaminants that can lead to reduced cooling efficiency and corrosion of cooling system components.

Overheating Issues and Troubleshooting

Overheating can be a serious issue for any engine, particularly one as finely tuned as the N55B30. Common signs of overheating include:

- Temperature Gauge Reading High: If the needle moves towards the red zone, it’s a clear indicator of an overheating issue.

- Coolant Leaks: Puddles of coolant under the car or a low coolant reservoir level can point to leaks in the system.

- Steam from Under the Hood: Steam or a hot engine smell indicates that the coolant temperature is too high and is boiling over.

If overheating occurs, it’s important to stop the vehicle as soon as it’s safe to do so and turn off the engine to prevent damage. Troubleshooting should begin with checking for leaks, ensuring the coolant level is adequate, and assessing the condition of the radiator, water pump, thermostat, and hoses.

It’s often best to have a professional mechanic diagnose and repair any cooling system issues to avoid potential engine damage.

Engine Air Filter

An engine air filter is a guard against airborne contaminants, ensuring that the air entering the combustion chamber is as clean as possible. For the BMW N55B30 engine, maintaining a clean air filter is essential for performance and longevity.

The air filter’s primary role is to catch dust, pollen, and other airborne particles before they can enter the engine. A clean filter ensures optimal air flow, which is crucial for maintaining the engine’s power output and efficiency. A clogged filter can restrict air flow, leading to decreased horsepower, reduced fuel economy, and an increased risk of engine wear due to unfiltered contaminants.

BMW recommends replacing the engine air filter every 60,000 miles under normal driving conditions. However, for vehicles driven in dusty or polluted environments, the air filter should be inspected more frequently and replaced as needed. Some performance-oriented drivers opt for shorter intervals to ensure maximum engine breathing capability and performance.

How to Replace the Engine Air Filter

Replacing the air filter is a straightforward process that most N55B30 owners can do themselves:

- Locate the Air Filter Housing: Open the hood and find the air filter housing, typically located near the front of the engine bay.

- Remove the Housing Cover: Release the clips or screws securing the housing cover and lift it to access the filter.

- Replace the Filter: Take out the old air filter, clean any debris from the housing, and insert the new filter.

- Reassemble the Housing: Place the cover back on and secure it with the clips or screws.

Using a genuine BMW air filter or a high-quality aftermarket alternative that meets OEM specifications is important to ensure the best fit and filtration.

Tuning and Modifications

Optimizing the performance of the BMW N55B30 engine can be an exhilarating venture for enthusiasts. Through careful tuning and modifications, the engine’s output and responsiveness can be significantly enhanced.

Owners looking to improve performance often start with the following upgrades:

- Cold Air Intake Systems: By providing a more direct airflow path and cooler air to the engine, these systems can improve throttle response and modestly increase horsepower.

- Exhaust Systems: Upgrading to a high-flow exhaust system reduces back pressure, allowing the engine to breathe more easily and can add to the engine’s power while creating a more aggressive exhaust note.

- Intercoolers: An upgraded intercooler can decrease the temperature of the charged air entering the engine, increasing density and potential power output, especially important for turbocharged engines like the N55.

ECU Tuning and Remapping

One of the most impactful modifications for the N55B30 engine is ECU tuning or remapping. This process adjusts the engine control unit (ECU) parameters for fuel delivery, ignition timing, and boost pressure, among others. ECU tuning can yield significant gains in power and torque, particularly when combined with other modifications.

- Stage 1 Tuning: Generally involves software changes that can be applied to a stock engine to optimize performance without additional hardware upgrades.

- Stage 2 and Beyond: These tunes are more aggressive and typically require additional modifications like high-flow downpipes, larger intercoolers, or upgraded turbochargers.

Aftermarket Parts and Considerations

When selecting aftermarket parts, consider the following:

- Quality and Compatibility: Choose reputable brands known for quality and ensure compatibility with the N55B30 engine.

- Performance Goals: Match the modifications to your performance goals, whether it’s improved acceleration, track-day performance, or increased efficiency.

- Regulatory Compliance: Check local regulations, as some modifications may affect emissions compliance and vehicle warranty.

- Professional Installation: Some upgrades may require professional installation and tuning to ensure proper function and to avoid damaging the engine.

FAQs

What is the lifespan of the N55B30 engine?

The lifespan of the N55B30 engine can vary based on maintenance, driving habits, and other factors. With proper care and regular servicing, many N55 engines have been known to exceed 200,000 miles without major issues. Adherence to BMW’s maintenance schedule and the use of quality parts and fluids play a significant role in ensuring the longevity of the engine.

How often should the N55B30 engine be serviced?

BMW recommends servicing the N55B30 engine approximately every 10,000 miles or once a year, whichever comes first, for routine maintenance such as oil changes and inspections. Some components, like spark plugs and air filters, have longer service intervals, typically around 60,000 miles. Always refer to the vehicle’s service manual for the most accurate maintenance schedule.

Can the N55B30 engine use alternative fuels?

The N55B30 engine is designed to run on premium unleaded gasoline. Using alternative fuels like E85 ethanol or biodiesel is not recommended unless the engine has been specifically modified and tuned to accommodate such fuels. Using non-approved fuels without proper modifications can lead to engine damage and voiding of the vehicle’s warranty.

What are the signs of N55B30 engine failure?

Signs of potential engine failure in the N55B30 include unusual noises such as knocking or rattling, loss of power, consistent overheating, a significant increase in oil consumption, and persistent check engine lights. If any of these symptoms occur, it is crucial to have the vehicle inspected by a professional mechanic to diagnose and address any issues promptly.

How does the N55B30 compare to its competitors?

The N55B30 engine is often compared favorably to its competitors for its balance of performance, efficiency, and reliability. It offers a solid combination of a high-revving nature and robust low-end torque. Compared to other engines in its class, the N55B30 stands out for its innovative use of a single twin-scroll turbocharger, which contributes to its smooth power delivery and responsiveness.

Hi Dan,

I bought the 335i GT F34 a few days ago. Seems fantastic. I am a little surprised about the warm-up time when the engine reaches the operational temperature for full-power usage. It takes around 20 mins in the city traffic. Is that normal? As I heard the N55 engine has (sometimes) thermostat problem or oil cooler troubles. So sorry for asking but I did not find this information in your article even if it’s very useful.

regards

Stanislav

Hi, Stanislav. BMW uses electric pumps that are driven by a composite impeller, which do not have a very long lifespan. It is important to note – the thermostat is also a common point of failure. Due to the excessive labor to replace a water pump it is recommended you replace the thermostat along with the pump.

BUT, in case of a water pump’s failure you will get a rapid over-heating. In your case, I’m not seeing any problem.