The BMW M52 engine series represents a pivotal point in the evolution of BMW’s six-cylinder power units. Introduced in the mid-1990s, the M52 was a technological leap forward from its predecessor, the M50, offering enhancements in efficiency, power, and environmental friendliness.

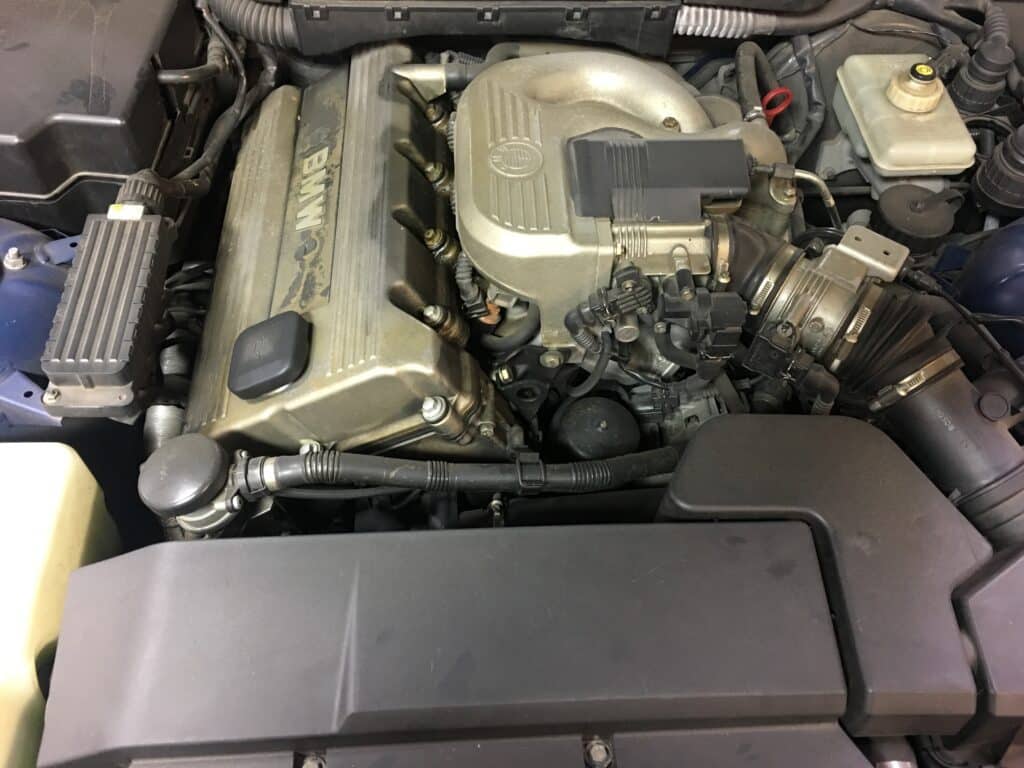

Constructed with a light alloy block and featuring VANOS, BMW’s variable valve timing technology, the M52 engine series improved upon the driving dynamics without compromising reliability. This series of engines powered a wide array of BMW’s most popular models during its production run. They were the basis for numerous performance variants, making them a cornerstone in BMW’s engine lineup.

Within the esteemed M52 family, the M52B25 variant emerged as a particularly notable engine. Displacing 2.5 liters, this inline-six engine offered a harmonious blend of performance and efficiency, making it a sought-after choice for enthusiasts and everyday drivers alike.

It was a powerplant that delivered smooth and linear acceleration, imbued with the responsiveness and refinement that BMW drivers had come to expect.

The M52B25 found its home in several key models, such as the E36 3 Series and E39 5 Series, contributing significantly to the driving pleasure and success of these models in the late ’90s. Its balance of power, precision engineering, and potential for longevity solidified the M52B25’s reputation and helped maintain BMW’s status as a producer of premium, driver-focused vehicles.

Engine Heritage and Development

The M52 engine family heralds from a rich pedigree of BMW’s straight-six engines, a configuration synonymous with the brand since the 1930s. The lineage of BMW’s inline-six engines is a testament to the company’s commitment to smooth power delivery and a balanced driving experience.

The inception of the M52 series in 1994 marked a significant milestone in this continuous evolution. BMW sought to create an engine to uphold its performance heritage while meeting the burgeoning demands for more environmentally friendly vehicles.

The M52 was conceived as a successor to the M50, which had already set high standards in terms of power and efficiency. While the M50 introduced VANOS, BMW’s innovative variable valve timing system, on the intake camshaft, the M52 expanded upon this technology. It refined the VANOS system and extended its efficiency gains across a broader rev range, leading to better fuel economy and more immediate throttle response.

From a structural standpoint, the M52 represented a major advance. While the M50 was built with an iron block, the M52 transitioned to a lighter aluminum block with a Nikasil coating for the cylinder linings, which provided a high level of wear resistance.

This was later changed to steel liners with the introduction of the M52TU (‘Technical Update’) in late 1998, to address issues with high sulfur content in certain fuels. The use of aluminum helped reduce the engine’s overall weight, contributing to improved vehicle handling and fuel efficiency.

The engine also introduced additional technological advancements, such as the electronic throttle control, which replaced the traditional mechanical setup, providing more precise control over the engine’s power delivery.

Additionally, BMW incorporated a more sophisticated engine management system that could adapt to various conditions and driving styles, further enhancing the driving experience.

The M52B25, in particular, was developed to offer a mid-range option in BMW’s lineup. It was engineered to provide an optimal balance of power and torque, with a displacement of 2.5 liters that was ideal for a broad spectrum of vehicles, from the compact 3 Series to the larger 5 Series and even the Z3 roadster.

It became a popular choice for those who sought BMW’s trademark driving dynamics without the higher running costs associated with the larger engines in the series.

M52B25 Engine Specs

The BMW M52B25 engine is a marvel of engineering, encapsulating the best of BMW’s design philosophies and technical prowess. With its inline-six configuration, the M52B25 is inherently balanced, providing smooth operation and a characteristic silky power delivery that is both responsive and refined.

The M52B25 displaces 2.5 liters, courtesy of an 84 mm bore and a 75 mm stroke. It operates on a DOHC (Double Overhead Camshaft) design, allowing two camshafts in the cylinder head, one for intake valves and one for exhaust valves. This design is coupled with BMW’s VANOS system on the intake camshaft, improving engine breathing and, thereby, performance and fuel economy.

The engine’s construction utilizes an aluminum block and head, which not only reduces weight but also helps with better heat dissipation. Using lightweight materials contributes to the vehicle’s overall balance and handling characteristics.

The M52B25’s cylinder bore is lined with Nikasil, a nickel-silicon carbide coating, which offers exceptional durability and a low-friction environment for the pistons.

Regarding performance, the M52B25 stands out with its 170 horsepower at 5,500 rpm and 181 lb-ft of torque at 3,950 rpm. This power output ensures brisk acceleration and ample mid-range torque, making for an engaging driving experience whether navigating city streets or cruising on the highway.

The table below summarizes the key specifications of the BMW M52B25 engine:

| Specification | Detail |

|---|---|

| Engine Configuration | Inline-6 |

| Displacement | 2.5 L (2,494 cc) |

| Bore x Stroke | 84 mm x 75 mm |

| Compression Ratio | 10.5:1 |

| Power Output | 170 hp @ 5,500 rpm |

| Torque Output | 181 lb-ft @ 3,950 rpm |

| Induction | Naturally Aspirated |

| Fuel System | Sequential MPI (Multi-Point Injection) |

| Valvetrain | DOHC with VANOS (Variable Valve Timing) |

| Block Material | Aluminum |

| Cylinder Lining | Nikasil |

| Recommended Fuel | Premium Unleaded |

These specifications paint a picture of an engine that was designed for performance and efficiency while still maintaining the classic BMW driving feel. The M52B25 provided a level of sophistication and reliability that was indicative of BMW’s engineering standards during its era.

Overall, the M52B25’s blend of advanced materials, meticulous design, and performance tuning resulted in an engine that offered an optimal balance of power, smoothness, and efficiency, making it a standout power unit in BMW’s mid-range lineup.

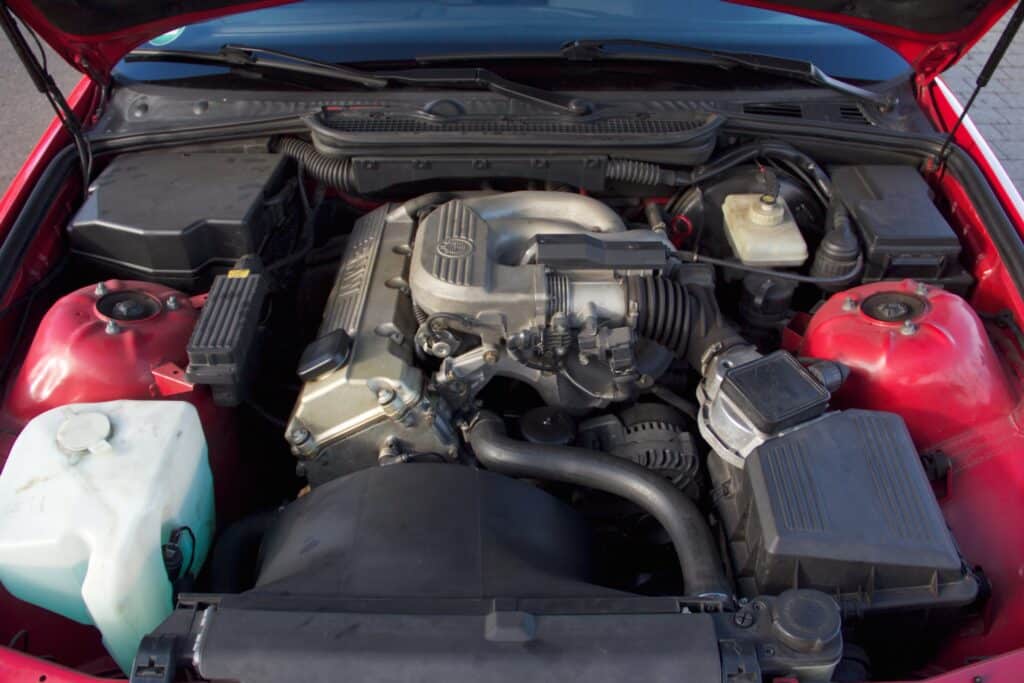

Under the Hood: Engine Components

Delving into the heart of the BMW M52B25 engine reveals a symphony of precision components working in unison to deliver the performance BMW is known for. Each component is engineered to exacting standards, ensuring the M52B25 operates with the efficiency and smoothness expected from a premium automaker.

Cylinder Block and Head

At the core of the M52B25 engine lies its robust aluminum cylinder block, chosen for its balance of strength and lightness. The block houses six cylinders in a straight line, a hallmark of BMW’s engineering approach to achieving a smooth and balanced power delivery.

Attached to this block is the aluminum cylinder head, which features an advanced design that supports efficient airflow and combustion.

The head is equipped with four valves per cylinder—two for intake and two for exhaust—facilitating better breathing for the engine. This configuration is optimized to work with the VANOS system, which precisely adjusts the timing of the valves opening to match the engine’s speed and load, thereby improving performance and efficiency.

Pistons, Rings, and Connecting Rods

Moving within the cylinder block are the pistons, which are engineered to withstand the rigors of high-speed operation while maintaining minimal weight. The piston rings provide a critical seal that maintains compression and manages oil distribution, ensuring each power stroke is as effective as possible.

The connecting rods link the pistons to the crankshaft, translating the linear motion of the pistons into the rotational force that ultimately drives the wheels.

Camshafts and Valve Train

The M52B25 features a dual overhead camshaft (DOHC) design, with one camshaft operating the intake valves and the other controlling the exhaust valves. This setup is integral to the engine’s ability to breathe efficiently at high RPMs, a characteristic that contributes to its spirited performance.

The valve train showcases BMW’s commitment to precision, with lightweight components that reduce inertia, allowing the engine to rev quickly and smoothly. The system is meticulously calibrated to ensure that each valve operates with pinpoint accuracy, a necessity for maintaining the tight tolerances required for the engine to run at peak efficiency.

Engine Management

The BMW M52B25 engine’s performance and efficiency are greatly influenced by its sophisticated engine management systems, including the fuel injection and ignition systems, guided by a highly intelligent Engine Control Unit (ECU) and an array of precision sensors.

Fuel Injection and Ignition Systems

At the heart of the M52B25’s fuel delivery is the Sequential Multi-Point Injection (MPI) system, which administers fuel directly into the intake port of each cylinder. This precise fuel metering is essential for achieving the optimal air-fuel mixture, resulting in efficient combustion and responsive throttle characteristics.

The MPI system’s responsiveness allows for adjustments in fuel delivery that are almost instantaneous, adapting to the driver’s demands and varying driving conditions.

The ignition system of the M52B25 is equally advanced, with a coil-on-plug design that assigns an individual ignition coil to each spark plug. This direct ignition setup eliminates the need for a distributor and provides a strong, consistent spark for each combustion cycle. The benefits are a smoother idle, better power delivery, and increased fuel efficiency.

Engine Control Unit (ECU) and Sensors

The orchestration of the fuel injection and ignition systems is managed by the ECU, an onboard computer that is the brain of the engine management system. The ECU processes data from a network of sensors that monitor everything from engine speed (RPM) and temperature to the oxygen content in the exhaust gases.

Key sensors include the Mass Air Flow (MAF) sensor, which measures the volume and density of air entering the engine; the Crankshaft Position Sensor, which informs the ECU of the engine’s rotational speed and position; and the Oxygen Sensors (O2 sensors), which help maintain the correct air-fuel ratio by monitoring the exhaust for oxygen content.

These sensors feed a constant stream of data to the ECU, which then adjusts the injection timing, fuel quantity, and ignition timing to optimize performance and emissions. The ECU can make these real-time adjustments, ensuring the engine runs smoothly under all operating conditions.

The M52B25’s engine management system also has self-diagnostic capabilities. When a sensor provides readings that deviate from the expected range, the ECU records a fault code and, in many cases, triggers the Check Engine light on the dashboard. This diagnostic function aids technicians in quickly identifying and resolving issues.

BMW M25B25 Engine Oil Capacity

The BMW M25B25 engine requires 6.9 quarts of 0W-30 oil with a filter replacement.

Proper lubrication is vital for the health and longevity of any engine, especially one with the precision engineering of the BMW M52B25. The type of oil used and its maintenance schedule are crucial in ensuring the engine runs smoothly and maintains its performance over time.

Recommended Oil Types for M52B25

BMW has specific recommendations for the type of oil suitable for the M52B25 engine to maintain its designed performance and efficiency. The manufacturer typically suggests a fully synthetic oil that meets its Longlife-01 specification.

This type of oil is engineered to withstand the high temperatures and stresses found within the M52B25 without breaking down or losing viscosity.

The recommended viscosity for the M52B25 is 5W-30 or 5W-40, depending on the climate and driving conditions. These multi-grade oils provide the necessary fluidity for cold starts while maintaining enough thickness to protect engine components at high operating temperatures.

Oil Capacity and Change Intervals

The M52B25 engine has an oil capacity of approximately 6.5 liters (6.9 quarts), including the filter. It’s essential to adhere to this capacity to ensure optimal lubrication without the risk of overfilling, which can lead to increased pressure and potential seal damage.

As for the oil change intervals, BMW initially recommended service every 15,000 miles or 12 months, whichever came first. However, many enthusiasts and experienced mechanics advocate for more frequent oil changes to extend the engine’s life.

A conservative approach would be to perform oil changes every 7,500 miles or once a year, especially if the car is used for frequent short trips, city driving, or high-performance situations, which can all contribute to oil contamination and breakdown.

It’s also worth noting that regular oil level checks between changes are essential. The M52B25 does not consume excessive amounts of oil, but monitoring the level ensures any potential leaks or consumption issues are caught early.

Fuel Consumption

The BMW M52B25 engine, while known for its smooth power delivery and performance, also exhibits a level of fuel efficiency that is commendable for its class and era. Understanding the average fuel economy of the M52B25, as well as the factors that influence its fuel consumption, is vital for drivers looking to maximize efficiency.

The M52B25 engine is rated to deliver a fuel economy that can be quite variable, depending on several factors, including driving habits and conditions. On average, vehicles equipped with this engine achieve approximately 20-30 miles per gallon (mpg).

More specifically, drivers might expect around 20 mpg in the city and up to 30 mpg on the highway under optimal conditions. These figures are approximate and can be influenced by numerous variables.

Factors Affecting Fuel Consumption

- Driving Behavior: Aggressive acceleration and high-speed driving can significantly increase fuel consumption. Smooth, gradual acceleration and adhering to speed limits tend to improve fuel economy.

- Vehicle Maintenance: A well-maintained engine runs more efficiently. Regular servicing, including oil changes, air filter replacements, and spark plug checks, are essential for optimal fuel economy.

- Tire Pressure: Under-inflated tires can cause higher rolling resistance, which leads to increased fuel consumption. Keeping tires inflated to the manufacturer’s recommended pressure is important.

- Weight and Aerodynamics: Extra weight, such as heavy cargo or unnecessary items in the trunk, can cause the engine to work harder and consume more fuel. Similarly, anything that affects the aerodynamics, like open windows or roof racks, can increase drag and decrease fuel efficiency.

- Use of Electrical Accessories: The frequent use of electrical accessories such as air conditioning and heated seats increases the load on the engine, leading to higher fuel consumption.

- Traffic Conditions: Stop-and-go traffic in urban environments can lead to lower fuel economy than steady driving conditions.

- Fuel Quality: The type of fuel used can also affect the engine’s efficiency. Higher octane fuel, as BMW recommends, can ensure proper combustion and performance.

- Engine Health: Worn components, such as oxygen sensors or a malfunctioning fuel injection system, can adversely affect fuel consumption.

To achieve and even surpass average fuel economy figures, owners of vehicles with the M52B25 engine should consider important factors and drive mindfully. Regular maintenance and attention to driving habits are crucial to ensure efficient and economical performance of the M52B25 engine throughout its lifespan.

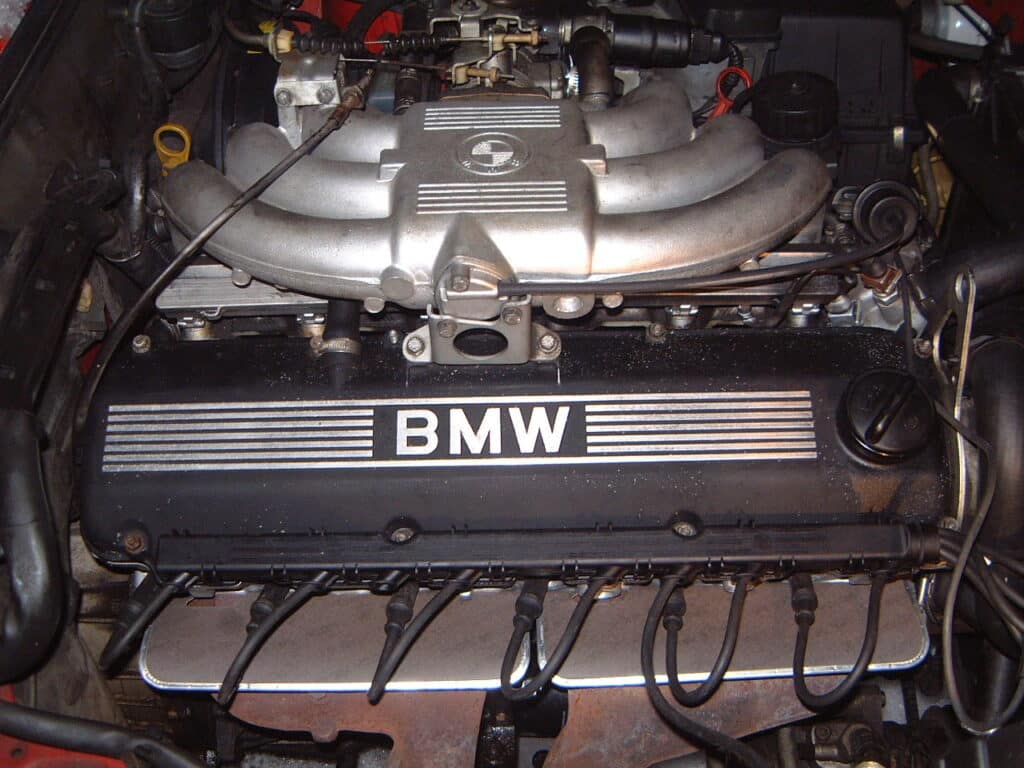

Engine Firing Order

The firing order of an engine is a specific sequence in which the spark plugs fire, igniting the air-fuel mixture in each cylinder. This sequence is critical for balancing the engine’s power delivery and minimizing vibrations. For the BMW M52B25 engine, the firing order is crucial to its smooth operation and characteristic inline-six performance.

The firing order for the BMW M52B25 engine is 1-5-3-6-2-4. This means that the first cylinder to fire is cylinder number 1, followed by cylinder number 5, and so on. The sequence promotes even power distribution across the crankshaft, ensuring smooth engine operation. The numbers correspond to the position of the cylinders, with cylinder number 1 typically being at the front of the engine, where the serpentine belt is located.

The specific firing order of the M52B25 brings several benefits:

- Balance: Inline-six engines are inherently well-balanced because of the equal spacing of the firing impulses. The 1-5-3-6-2-4 firing order contributes to this balance by optimizing the intervals between combustion events, which results in less vibration and a smoother-running engine.

- Power Delivery: A well-ordered firing sequence allows for more consistent and linear power delivery. This makes the driving experience more predictable and enjoyable, particularly regarding acceleration and engine response.

- Reduced Stress on Components: An smooth engine experiences less mechanical stress. The firing order of the M52B25 ensures that the forces are evenly spread across the engine’s internal components, contributing to longer engine life and reliability.

- Acoustic Characteristics: The firing order also influences the engine’s sound. The M52B25 is known for its distinctive straight-six engine note, which is partially a result of its firing order, producing a balanced and smooth sound that is often associated with higher-end performance cars.

Ignition System: Spark Plugs and Gap

The ignition system of the BMW M52B25 engine plays a pivotal role in its operation, ensuring that the fuel-air mixture within each cylinder is ignited efficiently and at the correct time. Central to this system are the spark plugs, which must be carefully selected and maintained to preserve engine performance and health.

Recommended Spark Plugs and Gap Settings

For the M52B25 engine, BMW recommends high-quality spark plugs that can withstand the high temperatures and pressures within the combustion chamber. Typically, these are high-performance iridium or platinum-tipped spark plugs known for their longevity and superior electrical conductivity.

The specific part numbers can vary depending on the manufacturer, but all should comply with BMW’s original equipment specifications.

The correct spark plug gap for the M52B25 engine is typically set between 0.7 mm to 0.8 mm. This gap is critical as it determines the size of the spark that ignites the air-fuel mixture. Too narrow of a gap may result in a weak spark, leading to incomplete combustion, while a gap that is too wide can cause misfires, particularly under heavy loads or high RPMs.

Maintenance Schedule for Spark Plugs

BMW suggests replacing the spark plugs on the M52B25 engine every 60,000 miles or so. However, this interval may be shorter if the vehicle is subject to severe use, such as frequent short trips, extended idling, or high-performance driving.

Symptoms that might indicate the need for spark plug replacement sooner include rough idling, a noticeable drop in power, increased fuel consumption, or difficulties starting the engine.

Regular inspections during scheduled maintenance are essential to identify any signs of wear or deposits that could affect the spark plug’s performance. When replacing spark plugs, it’s crucial to use the correct tightening torque to avoid damaging the cylinder head or the plugs themselves.

Timing Belt or Chain

The BMW M52B25 engine is equipped with a timing chain rather than a belt, which is a critical component in synchronizing the crankshaft and camshaft rotations. This synchronization ensures that the engine’s valves open and close at the correct times during the intake and exhaust strokes.

Timing Belt or Chain: Characteristics and Durability

Timing chains are known for their durability and generally have a longer service life than timing belts. Made of metal, they are less likely to snap and typically do not require regular replacement as part of preventive maintenance. In the M52B25, the timing chain is designed to last the engine’s lifetime under normal operating conditions.

However, it is not immune to wear and tear, and its longevity can be affected by oil quality and change intervals, as proper lubrication is crucial for the chain’s health and its associated sprockets and tensioners.

Timing System Maintenance

While the timing chain itself is robust, the M52B25’s timing system does include other components that may require attention over time. The chain tensioners and guide rails can wear out or become damaged, potentially leading to chain slackness or, in extreme cases, jumping teeth on the sprockets, which can cause timing issues and potentially severe engine damage.

It’s recommended to listen for any signs of timing chain issues, such as a rattling noise from the front of the engine, especially on cold starts. This could indicate a stretched chain or worn tensioners and guides. If any such symptoms are present, a thorough inspection by a qualified technician is advised.

Although there’s no specific replacement interval for the timing chain, it’s prudent to inspect it during major engine checkups, which typically occur every 100,000 miles.

Any service involving the timing chain is complex and should be performed by a professional with experience in BMW engines to ensure the correct timing is set, as improper installation can result in poor performance or engine damage.

Cooling System

The cooling system in the BMW M52B25 engine is a critical component that maintains optimal operating temperatures and prevents overheating. The system uses a mixture of water and antifreeze/coolant, which must meet BMW’s specifications for corrosion protection, boiling point, and freezing resistance.

For the M52B25, a 50/50 mix of BMW-approved antifreeze and distilled water is often recommended. This not only ensures proper thermal regulation but also protects against corrosion and scale buildup within the cooling channels.

Cooling System Maintenance and Tips

Regular maintenance of the cooling system is vital. The coolant should be replaced every 2 to 3 years to maintain its protective properties. During this service, a full inspection of the cooling system’s components, including the radiator, hoses, and thermostat, should be performed to identify any potential leaks or wear.

It’s also advisable to periodically check the coolant level and top it off if necessary. However, significant drops in coolant levels between services may indicate a leak, which should be addressed promptly to avoid engine damage from overheating.

Keeping the front of the radiator clear of debris, such as leaves or dirt, ensures adequate airflow and cooling efficiency. Additionally, during colder months, ensuring the antifreeze is at the correct concentration will prevent freezing and cracking in the engine block or radiator.

Air Intake System

The engine air filter is an essential part of the M52B25’s air intake system. It traps dust, pollen, and other airborne contaminants before they can enter the engine. A clean air filter is crucial for maintaining proper airflow, which is necessary for the engine to mix the right amount of air with fuel, achieving optimal combustion and performance.

BMW recommends replacing the engine air filter approximately every 30,000 miles, which can vary based on driving conditions. Driving in dusty or polluted environments may necessitate more frequent changes.

Importance of Air Quality for Engine Performance

The quality of the air entering the engine can greatly impact its performance. Clean air is necessary for efficient combustion, as contaminants can hinder airflow and degrade the air/fuel mixture, resulting in reduced power, increased fuel consumption, and higher emissions.

Moreover, a dirty air filter can lead to an accumulation of deposits on internal components, such as the intake valves and combustion chamber, which can cause a range of engine issues.

BMW M52B25 Engine Problems

The BMW M52B25 engine, while revered for its smooth operation and durability, is not without its share of common issues. Recognizing these problems and understanding how to troubleshoot them is crucial for maintaining the engine’s performance and longevity.

Known Issues with the M52B25 Engine

- Cooling System Failures: One of the most prevalent issues with the M52B25 is the failure of the cooling system components. The water pump and thermostat are particularly prone to wear, leading to overheating. The plastic components of the cooling system, such as the radiator end caps and coolant expansion tank, can become brittle over time and crack, resulting in coolant leaks.

- VANOS System Wear: The Variable Valve Timing (VANOS) system can suffer from seal degradation and solenoid failure. Symptoms include a loss of power, rough idling, and a rattling noise from the front of the engine.

- Oil Leaks: Common areas for oil leaks include the valve cover gasket, oil filter housing gasket, and oil pan gasket. These leaks can lead to a decrease in oil levels and potential damage to engine components if not addressed.

- Air Mass Meter Failure: The air mass meter, also known as the mass airflow sensor (MAF), can fail, causing the engine to run rich or lean. This failure may trigger a check engine light and result in poor fuel economy and performance.

Diagnostic Tips for Common Problems

When diagnosing issues with the M52B25, a systematic approach is beneficial:

- Overheating: If the engine is running hot, check the coolant level first. Inspect for leaks around the radiator, hoses, water pump, and expansion tank. Assess the operation of the thermostat and the water pump; a failed pump may not circulate coolant effectively, while a stuck thermostat can prevent coolant from flowing through the engine.

- VANOS Issues: Listen for the telltale VANOS rattle, indicating worn seals or solenoid issues. Performance diagnostics using a BMW-specific scanner can reveal VANOS-related fault codes. VANOS seal replacement kits are available and can be a cost-effective solution.

- Oil Leaks: Visually inspect the engine for signs of oil. Pay particular attention to the common leak points mentioned earlier. Clean the engine thoroughly and monitor for fresh leaks to confirm the source.

- Air Mass Meter: A faulty MAF sensor can often be diagnosed with an OBD-II scanner that reads engine fault codes. Performance symptoms may include hesitation during acceleration and difficulty starting. Sometimes, cleaning the MAF sensor can restore functionality, but replacement is necessary if the problem persists.

It’s also wise to conduct routine scans with a diagnostic tool even when the engine appears to be running normally, as some issues may not immediately present noticeable symptoms. Regular maintenance, such as timely oil changes and cooling system inspections, can prevent many of these issues from developing into more serious problems.

In addition to these common issues, owners need to listen to their engine and pay attention to the way the vehicle behaves. Unusual noises, changes in exhaust color or smell, or alterations in performance should prompt a diagnostic check.

By staying vigilant and addressing problems early, many of the common issues with the M52B25 can be resolved without significant expense or inconvenience, ensuring the engine continues to deliver the performance and reliability expected from a BMW powerplant.

Engine Reliability and Longevity

The BMW M52B25 is lauded for its durability and longevity, often surpassing the 200,000-mile mark with proper care. This engine’s resilience is rooted in its robust design and BMW’s engineering excellence, which have made it a mainstay in the BMW lineup for many years.

Crafted with an aluminum block and head for reduced weight and efficient heat dissipation and outfitted with innovative technologies like VANOS for variable valve timing, the M52B25 was designed to deliver not just performance but also reliability.

Its internals, from the crankshaft to the connecting rods and pistons, are engineered to withstand the demands of spirited driving—a testament to BMW’s commitment to quality.

Lifespan and Factors Influencing Engine Health

The typical lifespan of an M52B25, when maintained according to BMW’s service recommendations, can often reach or exceed the 200,000-mile threshold. However, longevity is influenced by several factors:

- Maintenance: Regular oil changes with the correct specification, timely replacement of the air and fuel filters, and adherence to the recommended service intervals are essential. Cooling system upkeep, including periodic coolant changes and inspections, is crucial to prevent overheating, which can significantly shorten engine life.

- Driving Habits: Engines that are subjected to regular high-rev driving, such as in performance or track settings, may experience accelerated wear if not properly maintained. Conversely, engines used in vehicles for gentle cruising can often enjoy an extended lifespan.

- Prompt Repairs: Addressing small issues before they evolve into larger problems is key. For example, a minor oil leak can lead to low oil levels and potential engine damage if ignored.

- Environment: Engines operating in extreme climates or harsh conditions may require more frequent service to maintain their health.

- Quality Parts and Fluids: Using BMW-approved parts and fluids can help maintain engine integrity and performance.

Maintenance and Care

Regular maintenance is the cornerstone of engine longevity, especially for a finely tuned piece of machinery like the BMW M52B25 engine. Adherence to a strict maintenance schedule and employing best practices can significantly extend the engine’s life, ensuring it continues to perform at its best.

To keep the M52B25 in optimal condition, the following maintenance tasks should be performed at the recommended intervals:

- Oil and Filter Change: Every 5,000 to 7,500 miles, or at least once a year, with a BMW-recommended fully synthetic oil and a quality oil filter.

- Coolant Flush: Every 2 to 3 years, regardless of mileage, using the correct BMW-approved coolant mixed with distilled water.

- Air Filter Replacement: Every 30,000 miles, or more frequently in dusty environments, to ensure proper air flow and engine breathing.

- Spark Plug Replacement: Approximately every 60,000 miles, or sooner if performance issues arise.

- Fuel Filter Replacement: Every 60,000 miles to maintain clean fuel delivery.

- Inspection of Belts and Hoses: Every 30,000 miles, or immediately if signs of wear or damage are present.

- Brake Fluid Change: Every 2 years to maintain braking efficiency and safety.

Tips for Prolonging Engine Life

In addition to following the maintenance schedule, the following tips can help prolong the life of your M52B25 engine:

- Warm-Up Period: Give the engine time to warm up before demanding high performance, especially in colder climates.

- Regular Checks: Frequently check your engine oil level, coolant level, and tire pressure between service intervals.

- Gentle Driving: Avoid hard accelerations and high-speed driving immediately after starting the engine. Gentle driving during the first few minutes of a journey can reduce wear.

- Address Issues Promptly: If the engine exhibits unusual behavior, such as rough idling, misfiring, or leaks, have it checked by a professional as soon as possible.

- Use Quality Parts: Always use OEM or OEM-equivalent parts for repairs to ensure compatibility and reliability.

- Keep Records: Maintain a detailed record of all maintenance and repairs. This helps in diagnosing future problems and can be valuable for resale.

- Clean Environment: Keep the engine bay clean to make it easier to spot leaks and changes which could indicate issues.

FAQs

What is the BMW M52B25 engine’s life expectancy?

The BMW M52B25 engine is known for its durability, and with proper maintenance, it is not uncommon for this engine to exceed 200,000 miles. Some well-maintained units have been reported to reach 300,000 miles or more. Regular servicing and addressing issues promptly are key to achieving a long service life.

What are the common symptoms of M52B25 engine problems?

Common symptoms of issues with the M52B25 engine include rough idling, a decrease in power or acceleration, increased oil consumption, coolant loss, overheating, and unusual noises like knocking or rattling. The presence of any of these symptoms warrants a thorough inspection to determine the underlying cause.

How often should I change the oil in my M52B25 engine?

It is generally recommended to change the oil in an M52B25 engine every 5,000 to 7,500 miles or at least once a year, whichever comes first. Using the correct grade of BMW-recommended fully synthetic oil is crucial for maintaining engine health.

Is the M52B25 engine prone to overheating?

Like any engine, the M52B25 can overheat if the cooling system malfunctions. Common cooling system issues include failed water pumps, leaking radiators, and brittle coolant hoses. Regular inspection and maintenance of the cooling system can prevent overheating problems.

Can I use synthetic oil in my M52B25 engine?

Yes, you can and should use synthetic oil in the M52B25 engine. BMW recommends fully synthetic oil for this engine to ensure optimal performance and protection under a wide range of operating conditions. Ensure that the oil meets BMW’s Longlife-01 specification for best results.