The BMW M54 engine series represents a pinnacle of engineering evolution in BMW’s illustrious history of producing inline-six powerplants. Introduced at the turn of the millennium, the M54 was a leap forward from its predecessor, the M52, offering enhancements in power, efficiency, and emissions. This engine family spanned various displacements and was the heart of numerous BMW models throughout the early to mid-2000s.

At the core of this series lies the M54B25 engine, a 2.5-liter variant that embodies the perfect balance between performance and practicality. It served as a mid-range option in the lineup, providing a harmonious blend of spirited dynamics and everyday usability.

The M54B25 was engineered to deliver a smoother, more refined driving experience and was a common power unit for a range of BMW models, including popular series such as the 3 Series and 5 Series, along with the X3 and Z4.

The significance of the M54B25 in BMW’s lineup cannot be overstated. It offered a more accessible entry point to the prestige and performance of the BMW brand without the higher running costs associated with larger engines.

Its presence bolstered BMW’s reputation for producing reliable, high-performing engines that could appeal to a broad audience—from the daily commuter to the driving enthusiast.

The M54B25 was not just a workhorse; it also incorporated BMW’s latest technology at the time, such as Double VANOS variable valve timing and an electronically controlled throttle, which contributed to a responsive and dynamic driving character.

These technological advancements, combined with BMW’s meticulous engineering standards, resulted in an engine that was both pleasurable to drive and capable of meeting the stringent environmental standards of its time.

In the pantheon of BMW engines, the M54B25 is remembered fondly for contributing to the brand’s legacy. It encapsulated the values of performance and innovation that enthusiasts have come to expect from BMW while also offering the reliability and efficiency required for everyday driving.

This engine variant is a testament to BMW’s commitment to pushing the boundaries of what is possible with internal combustion engine technology.

M54B25 Engine Specs

| Specification | Detail |

|---|---|

| Engine Displacement | 2.5 L (2494 cc) |

| Bore x Stroke | 84 mm x 75 mm |

| Compression Ratio | 10.5:1 |

| Horsepower | 184 HP @ 6,000 RPM |

| Torque | 175 lb-ft @ 3,500 RPM |

| Fuel System | Sequential MPI (Multi-Point Injection) |

| Engine Management | Siemens MS 43 |

| Valvetrain | DOHC with VANOS (intake and exhaust) |

| Redline | 6,500 RPM |

| Engine Block Material | Aluminum with iron liners |

| Cylinder Head Material | Aluminum |

| Valves per Cylinder | 4 |

| Emissions Standard | Meets EU3 and LEV standards |

The BMW M54B25 is a testament to BMW’s engineering prowess, exemplifying the delicate balance between performance, reliability, and efficiency. This inline-six engine has earned its place in BMW’s storied history of creating refined and powerful engines.

The M54B25 engine boasts a displacement of 2.5 liters, achieved through a bore of 84 mm and a stroke of 75 mm. This double overhead camshaft (DOHC) engine features BMW’s VANOS system on both the intake and exhaust camshafts, enhancing the engine’s efficiency and power delivery.

The construction reflects BMW’s commitment to quality and durability, with a lightweight aluminum block and cylinder head, iron cylinder liners, and a forged steel crankshaft.

The M54B25 also utilizes a more advanced Siemens MS 43 engine management system, which controls the fuel injection and ignition systems precisely, adapting to the driver’s demands and varying conditions to optimize performance and fuel economy.

The M54B25 was designed with a focus on reducing internal friction and increasing thermal efficiency. It employs a hypereutectic aluminum-silicon alloy for the pistons, which provides a low expansion rate and high thermal conductivity.

The connecting rods are made from forged steel, ensuring durability under high stress, while the Nikasil-coated aluminum cylinders offer excellent wear resistance and improved heat dissipation.

With an output of 184 horsepower at 6,000 RPM and 175 lb-ft of torque at 3,500 RPM, the M54B25 delivers a spirited driving experience that is both engaging and smooth. This engine’s power band is broad, thanks to BMW’s VANOS variable valve timing system, which adjusts timing on the fly to optimize performance and efficiency at all engine speeds.

Engine Heritage and Development

The BMW M54 engine family, introduced in the year 2000, was a significant step in the evolution of BMW’s illustrious six-cylinder lineage. Tracing its heritage back to the iconic M50, the M54 resulted from continuous refinement and innovation to enhance performance while meeting more stringent environmental regulations.

The M54’s design was heavily based on the M52, retaining the lightweight aluminum construction and the classic inline-six configuration revered for its smoothness and balance.

However, it was the innovations and improvements over the M52 that set the M54 apart. BMW engineers reworked the intake and exhaust manifolds for better flow, incorporated a fully electronic throttle control for sharper response, and upgraded the VANOS system for more precise valve timing. These improvements not only boosted power across the range but also improved fuel efficiency and reduced emissions.

The transition from M52 to M54 saw several key changes. The displacement of the M54B25 was slightly increased thanks to a larger bore and a longer stroke, resulting in 184 horsepower and a more robust torque curve. The M54 also saw the introduction of a new engine management system that provided more computing power, allowing for finer control of the engine’s functions.

The M54B25, in particular, benefited from these advancements, which provided a tangible improvement in drivability and power delivery over the M52. BMW’s use of more advanced materials and manufacturing techniques also resulted in improved reliability and durability of the engine.

What Cars Have A BMW M54B25 Engine?

- 2000-2002 E36/7 Z3 2.5i

- 2000-2006 E46 325i, 325xi, 325Ci

- 2000-2004 E46/5 325ti

- 2000-2004 E39 525i

- 2003-2005 E60/E61 525i, 525xi

- 2003-2006 E83 X3 2.5i

- 2002-2005 E85 Z4 2.5i

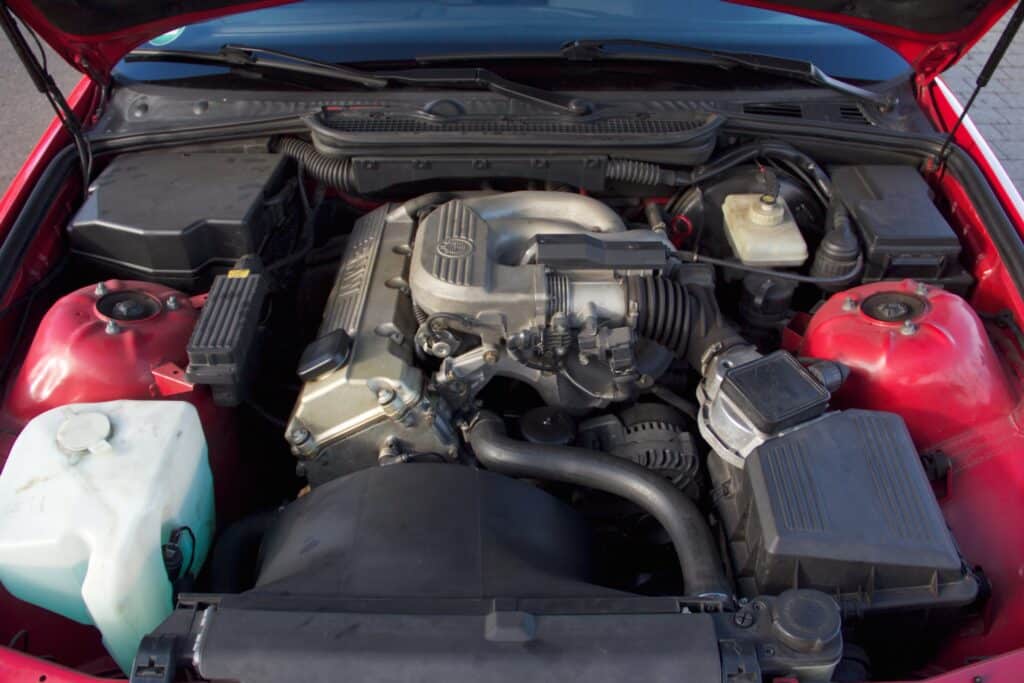

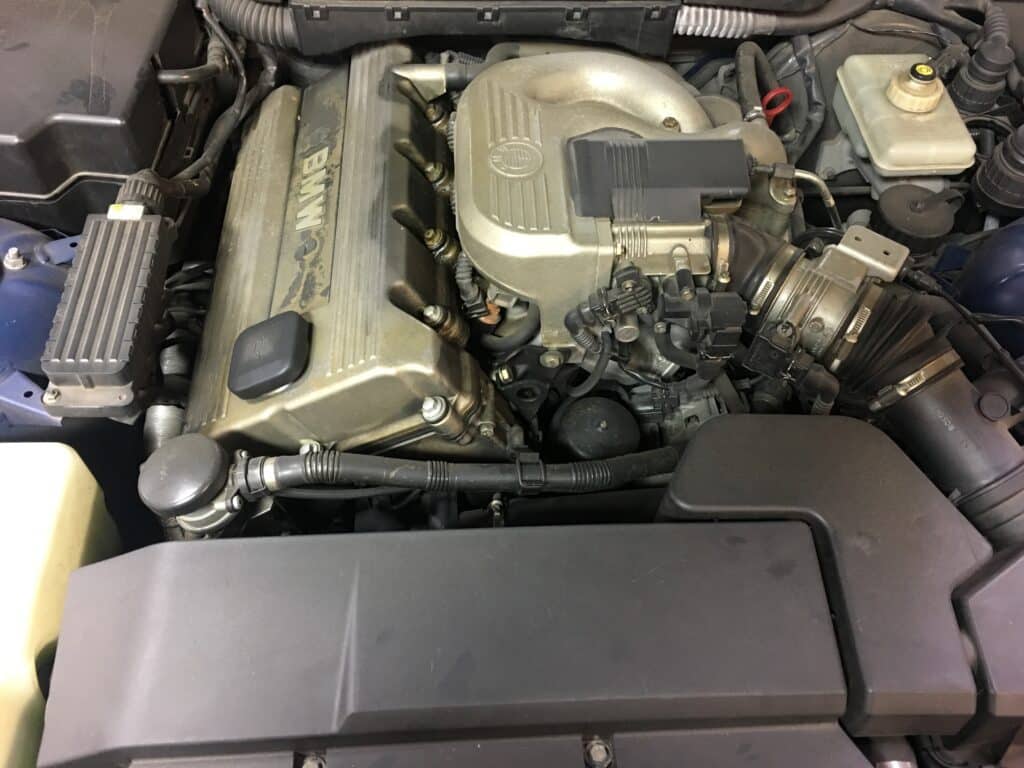

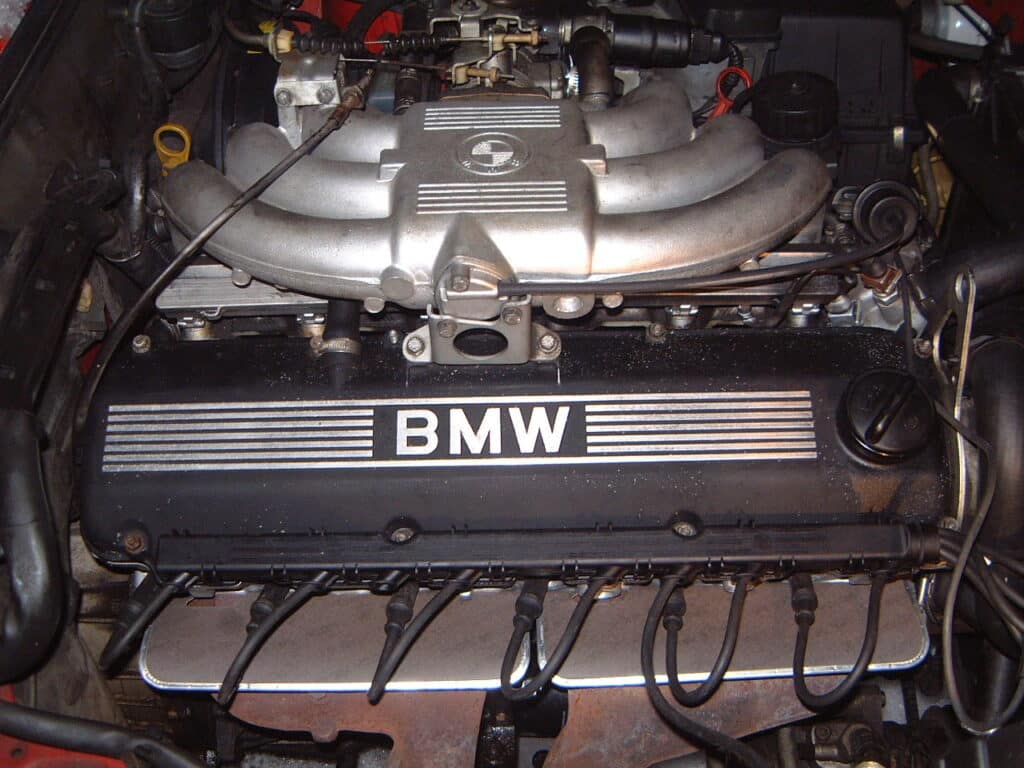

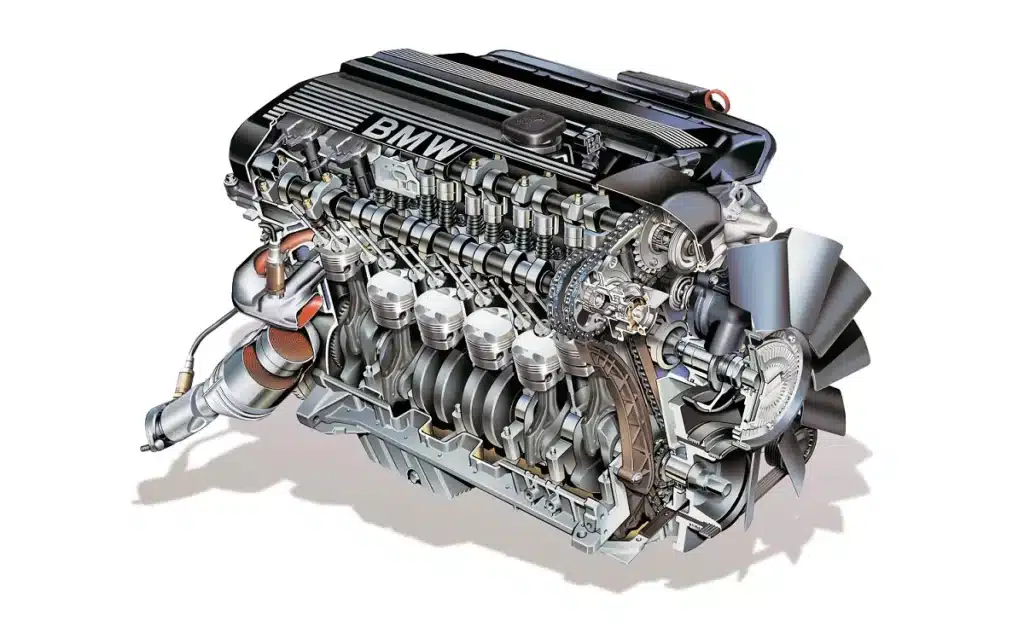

Under the Hood: Engine Components

Diving under the hood of the BMW M54B25 engine reveals a masterclass in automotive engineering, where each component is designed for performance and longevity.

Cylinder Block and Head Construction

The M54B25 features a lightweight aluminum cylinder block with cast-iron cylinder liners. This design choice strikes an optimal balance between the block’s overall weight and its ability to withstand the stresses of combustion. Aluminum, known for its excellent thermal conductivity, aids in heat dissipation, while the iron liners ensure durability and wear resistance.

The cylinder head, also constructed from aluminum, houses the dual overhead camshafts and is engineered to promote efficient airflow into and out of the combustion chambers. The precise casting of the cylinder head allows for smooth surfaces that minimize turbulence, ensuring a swift intake and exhaust gas flow, which is crucial for engine performance.

Pistons, Rings, and Connecting Rods Details

The pistons are a hypereutectic aluminum-silicon alloy selected for its high thermal conductivity and low expansion rate. These pistons are less prone to seizing and can withstand higher temperatures, making them ideal for performance applications. The piston rings are designed to provide a tight seal for optimal compression while minimizing oil consumption and blow-by.

Forged steel connecting rods connect the pistons to the crankshaft, chosen for their strength-to-weight ratio, ensuring they can handle the forces of high-speed operation without adding unnecessary bulk to the engine’s rotating assembly.

Camshafts and Valve Train Dynamics

The M54B25 employs BMW’s VANOS system on both the intake and exhaust camshafts, dynamically adjusting valve timing based on engine load and speed. This technology improves low-end torque and high-end power while also smoothing out idle and increasing fuel efficiency. The valve train itself consists of four valves per cylinder—two for intake and two for exhaust—optimized for rapid opening and closing to maximize engine breathing efficiency.

The M54B25’s engine components work harmoniously to deliver the quintessential BMW driving experience—smooth, powerful, and responsive, reflecting the brand’s commitment to precision engineering and high performance.

Engine Management

The BMW M54B25 engine is governed by a sophisticated engine management system that optimizes performance, fuel efficiency, and emissions control.

The fuel injection and ignition systems of the M54B25 are integral components managed by the Siemens MS 43 engine management system. This system incorporates advanced technology to control the engine’s operations, including fuel supply, fuel injection, and ignition.

Engine Control Unit (ECU) and Sensor Integration

At the core of the engine management is the Engine Control Unit (ECU), also known as the Digital Motor Electronics (DME) system. The ECU processes information from many sensors to monitor and adjust engine functions precisely. The sensors measure various parameters such as engine speed, temperature, air intake volume, and knock detection, which are critical for efficient engine operation.

Here’s how the system integrates various components:

- Fuel Supply: The M54B25 uses a non-return fuel system, which maintains a constant fuel pressure for the injectors, ensuring precise fuel delivery.

- Fuel Injection: The Siemens MS 43 DME controls the sequential multi-point fuel injection, providing the right amount of fuel to each cylinder when it’s needed.

- Ignition: The ignition system is fully electronic, with individual ignition coils for each spark plug, ensuring a strong and accurate spark for optimal combustion.

- Engine Sensors: The two knock sensors are part of the engine’s protective measures, adjusting the ignition timing to prevent damaging detonation.

- Electronic Throttle: An electronic throttle control replaces the traditional cable system, providing more responsive throttle action and integration with various drive modes.

The ECU is also responsible for self-diagnostic functions and adheres to OBD-II standards, storing diagnostic trouble codes (DTCs) for efficient troubleshooting.

Oil Capacity and Type

For the BMW M54B25, the lifeblood that ensures smooth operation is its engine oil. Selecting the right oil and adhering to change intervals is crucial for maintaining engine performance and longevity.

The M54B25 engine thrives on 5W-30 oil, which provides an optimal balance of viscosity for both cold starts and high-temperature operation. However, depending on driving conditions, 5W-40 can also be an excellent choice, especially for drivers who demand a bit more from their engine, such as frequent high-rpm driving or occasional track use.

With an oil capacity of 6.5 liters (6.9 quarts), the M54B25 has enough volume to ensure effective lubrication over extended periods. While older vehicles were often subject to the 3,000-mile change interval, advancements in engine design and oil technology have extended this period significantly for newer models like the M54B25.

Most BMW owner’s manuals recommend changing your oil every 15,000 miles. However, for those who drive under more demanding conditions, an oil change every 7,500 to 10,000 miles is a more prudent interval.

Importance of Oil Quality and Viscosity

Oil’s viscosity plays a pivotal role in the health of an engine. It must be thin enough to flow quickly during cold starts and thick enough to maintain film strength under high temperatures. This is particularly critical for engines with Variable Valve Timing (VVT) systems like BMW’s VANOS.

The oil’s viscosity directly influences the hydraulic pressure needed to adjust the camshafts. Modern BMW engines, including the M54B25, benefit from oils that offer good shear resistance, ensuring the oil maintains its protective qualities throughout its service life.

It’s worth noting that even oils within the same viscosity grade can vary slightly. For example, a Redline 0W-40 may have a different kinematic viscosity at operating temperature than a Motul 300V. This slight difference can affect the oil’s performance in critical engine systems. Therefore, drivers should choose a high-quality, shear-resistant oil that matches their driving habits and ambient conditions.

Fuel Consumption

Fuel efficiency is a critical aspect to consider when evaluating the performance of an engine. The BMW M54B25 is no exception, balancing power and fuel economy.

The M54B25 engine, specifically in the 525i model, has a reported fuel consumption of:

- Urban: 14.0 liters/100km

- Highway: 7.0 liters/100km

- Combined: 9.4 liters/100km

This translates to an average fuel economy of approximately 29 mpg UK or 24 mpg US.

Factors Influencing Fuel Efficiency

Several factors can affect the fuel efficiency of the M54B25 engine:

- Driving Habits: Aggressive acceleration and high-speed driving can significantly increase fuel consumption.

- Maintenance: Poor maintenance can lead to decreased fuel efficiency over time.

- Vehicle Load: Heavy loads or towing can increase fuel consumption.

- Tyre Pressure: Incorrect tyre pressure can cause higher fuel consumption due to increased rolling resistance.

- Environmental Conditions: Extreme temperatures and use of air conditioning can also affect fuel efficiency.

Comparison with Other BMW Engines

When compared to other engines in the BMW lineup, the M54B25 offers a balance between performance and fuel economy. For example:

- M54 vs. N52: The N52 engine is slightly more efficient than the M54, thanks to modern design features like Valvetronic and Double-VANOS.

- M52 vs. M54: The M52 engine has a higher compression ratio and makes more torque, but the M54 is more powerful and has better fuel economy.

Below is a table summarizing the MPG figures:

| Driving Condition | MPG (UK) | MPG (US) |

|---|---|---|

| Urban | 20.1 | 16.7 |

| Highway | 40.3 | 33.6 |

| Combined | 30.1 | 24.0 |

The M54B25 engine’s efficiency is commendable, especially considering its period and the technology available at the time. It is a testament to BMW’s commitment to combining driving pleasure with fuel economy.

Engine Firing Order

The firing order of an engine is the specific sequence in which each cylinder receives a spark to ignite the air-fuel mixture, causing the engine to run. The firing order is not only crucial for engine operation but also affects its balance, smoothness, and overall performance.

For the BMW M54B25 engine, the firing order is 1-5-3-6-2-4. This sequence is designed to optimize engine balance and smooth operation.

The inline-six engine, which includes the M54B25, has a natural advantage regarding smoothness due to its firing order. Unlike V-shaped engines, the straight-six configuration allows for pistons to move in perfectly synchronized pairs.

For example, as piston 1 moves down, piston 6 moves up, and so on for pairs 2 and 5 and 3 and 4. This natural pairing means that the primary forces inherently balance each other out, which reduces engine vibration and noise, leading to the renowned BMW silky-smooth acceleration.

Furthermore, in the 1-5-3-6-2-4 firing order, no two adjacent cylinders fire in succession, which is crucial for maintaining the engine’s balance. This staggered firing allows for consistent power distribution and minimizes vibrations, which can otherwise be transmitted through the engine block and into the vehicle’s chassis, causing discomfort for the occupants.

The BMW inline-six’s firing order ensures that none of the cylinders fire simultaneously, further contributing to the engine’s smoothness and efficiency. This firing order is a characteristic feature of BMW’s inline-six engines and is impossible with a V6 engine configuration, where the physical arrangement of the cylinders does not allow for such a perfect balance.

Timing System

The BMW M54B25 engine, which powers models such as the E39 5-Series and E46 3-Series, is equipped with a meticulously engineered timing system. This system utilizes a chain-driven double overhead camshaft (DOHC) to control the engine’s valves with precision. Each cylinder has four valves, two for intake and two for exhaust, making a total of 24 valves for the six-cylinder engine.

This robust design is managed by the Siemens MS 43 engine management system, which is complemented by BMW’s innovative VANOS technology—a variable valve timing mechanism that optimizes engine performance and efficiency.

The VANOS system plays a crucial role in the engine’s ability to adjust timing on the fly, contributing to the engine’s responsiveness and power delivery. However, despite the system’s advanced design, it is not without its maintenance needs and common issues.

Over time, the VANOS seals, made of a Teflon seal ring and a supporting O-ring, can deteriorate, particularly due to their incompatibility with synthetic oils. The VANOS solenoids, responsible for actuating the valves, also have a history of failing prematurely, an issue that previous owners may have encountered and addressed.

Symptoms of VANOS system malfunction include a noticeable decline in engine performance, erratic idling, and decreased fuel efficiency. To confirm VANOS-related problems, it is essential to perform a diagnostic scan with an OBD-II tool to identify any associated Diagnostic Trouble Codes (DTC).

To maintain the timing system’s integrity and prevent common issues, regular oil changes are critical, as clean oil is vital for the health of the VANOS system. Additionally, a proactive approach to maintenance, including the timely replacement of solenoids and seals, can help extend the life of the timing system and ensure the engine operates at its best. Overall, the M54B25’s timing system, with proper care, contributes to the engine’s reputation for smooth and reliable performance.

Cooling System

The cooling system of the BMW M54B25 engine is designed to keep it operating at an optimal temperature, but it requires meticulous maintenance to prevent common issues. The cooling system consists of several key components, including the radiator, thermostat, water pump, and a network of hoses and tanks.

Engine coolant specifications for the M54B25 call for a 50/50 mix of Genuine BMW coolant and distilled water. This specific blend is crucial for preventing corrosion and deposits within the cooling system while ensuring maximum heat dissipation.

The radiator in the M54B25 is robust by design, but it is equipped with plastic end tanks that can become brittle over time. These tanks are sealed to the radiator core with rubber gaskets, which can also degrade, leading to leaks. The cooling system’s efficiency relies on the free flow of coolant through these components, and any restriction or leakage can lead to overheating, especially in traffic or while idling.

The thermostat regulates the coolant flow to maintain the engine temperature within a specified range. It is designed to fail in the open position to prevent engine overheating, but replacement at the first sign of malfunction is recommended to avoid any risk.

For maintenance, it is essential to periodically inspect the cooling system for signs of wear or damage. The expansion tank is particularly vulnerable to developing cracks that can lead to leaks. Belts and pulleys should be checked for signs of wear and replaced as necessary, usually every 60,000 miles, to ensure that the water pump and alternator function correctly.

The water pump is another critical component, and while failures are not exceedingly common, it should be replaced based on age and mileage as a preventative measure. The latest BMW water pump designs use a plastic composite impeller, preferred for its balance and longevity over earlier metal designs.

Cooling system maintenance tips include:

- Regularly checking coolant levels and the condition of the coolant.

- Inspecting hoses, the radiator, and the expansion tank for cracks or leaks.

- Replacing the thermostat and water pump as a preventive measure during major service intervals.

- Bleeding the system to remove air pockets after any coolant service, as air in the system can lead to hot spots and inefficient cooling.

Air Intake System

The air intake system of the BMW M54B25 engine plays a pivotal role in its operation by ensuring that clean air is supplied to the engine for combustion. Air quality and filtration are critical because any contaminants entering the engine can cause abrasive wear, reducing efficiency and potentially causing damage over time. The air filter is the first line of defense against such contaminants.

For the M54B25 engine, the air filter needs to be of high quality to filter out dust, pollen, and other airborne particles effectively. Using the correct specifications for the air filter is essential to maintain the balance between adequate airflow and filtration. The wrong filter can restrict airflow, leading to a loss of power and efficiency, or allow too much debris through, which could harm the engine.

Change frequency for the air filter in the M54B25 engine is typically every 100,000 km or 62,000 miles under normal driving conditions. However, this interval may need to be shortened depending on the environment in which the vehicle is driven.

For example, driving in dusty or polluted areas requires more frequent changes. As a rule of thumb, the air filter should be inspected with every oil change, which occurs approximately every 5,000 miles or six months. If the filter appears dirty or clogged, it should be replaced regardless of the mileage.

To maintain the health of the M54B25 engine, it is recommended to use genuine BMW air filters or other high-quality aftermarket options that meet OEM specifications. Regular checks and timely replacement of the air filter will ensure that the engine performs efficiently, provides optimal fuel economy, and delivers the expected power output.

BMW M54B25 Engine Problems And Reliability

The BMW M54B25 engine is renowned for its smooth operation and reliability, but like any mechanical system, it has its share of common issues.

Known Issues with the M54B25 Engine

- VANOS System Failure: The Variable Valve Timing system can suffer from seal deterioration, leading to performance loss and rough idling.

- Cooling System Problems: The delicate cooling components, particularly the plastic expansion tank and water pump, are prone to failure.

- Oil Leaks: Common oil leak points include the oil filter housing gasket, valve cover gasket, and oil pan gasket.

- Air Mass Meter (MAF Sensor) Failure: A faulty MAF sensor can lead to poor engine performance and increased fuel consumption.

- DISA Valve Failure: The Differential Air Intake System (DISA) valve can fail, impacting the engine’s performance, especially at certain RPMs.

Tips for Diagnosing and Fixing Common Problems

VANOS System Issues

| Symptom | Diagnosis | Fix |

|---|---|---|

| Loss of power, rough idling | Use an OBD-II scanner to check for VANOS-related fault codes. | Replace the VANOS solenoids and seals. |

| Poor fuel economy | Listen for rattling noises from the front of the engine as a sign of VANOS wear. | Ensure timely oil changes with the correct specification to prevent premature wear. |

Cooling System Troubles

| Symptom | Diagnosis | Fix |

|---|---|---|

| Overheating, coolant leak | Inspect for visible cracks on the expansion tank and check for leaks. | Replace the expansion tank, water pump, and thermostat. Conduct a system bleed to remove air pockets. |

| High engine temperature | Check the operation of the thermostat and water pump. | Replace faulty components and ensure the use of proper coolant mix. |

Oil Leaks

| Symptom | Diagnosis | Fix |

|---|---|---|

| Oil spots under vehicle | Inspect gaskets and seals for wear or damage. | Replace the oil filter housing gasket, valve cover gasket, or oil pan gasket as needed. |

Air Mass Meter Failure

| Symptom | Diagnosis | Fix |

|---|---|---|

| Hesitation, stalling | Check the MAF sensor for contamination or failure using a specialized diagnostic tool. | Clean the MAF sensor with appropriate cleaner or replace it if defective. |

DISA Valve Malfunction

| Symptom | Diagnosis | Fix |

|---|---|---|

| Fluctuating engine power, poor idle | Listen for unusual noises or check for a fault code related to the DISA valve. | Replace the DISA valve with a new unit. |

When troubleshooting the M54B25 engine, a systematic approach is key. Starting with a diagnostic scan provides a solid foundation for understanding the issues at hand. For DIY enthusiasts, investing in a good OBD-II scanner and familiarizing oneself with BMW’s diagnostic codes can save time and money.

However, some problems may not throw a code and require a more hands-on approach, such as visually inspecting for leaks or listening for unusual noises. For instance, a rattling noise upon startup could suggest a problem with the VANOS system, whereas a hissing sound might indicate a vacuum leak.

Lastly, always use quality parts for repairs, preferably OEM or equivalent. This ensures the repairs last and the engine maintains its performance. Regular maintenance, as per BMW’s schedule, is the best preventive measure against many common issues.

By staying proactive with upkeep and addressing problems promptly, the M54B25 engine can provide a long service life with enjoyable driving experiences.

Engine Reliability and Longevity

The BMW M54B25 engine, a part of the reputable M54 family, is widely recognized for its durability and consistent performance. Launched in the early 2000s, it was designed to offer a balance of power and efficiency while maintaining the reliability expected from BMW’s inline-six engines.

This 2.5-liter powerplant has forged a reputation for longevity, with many units surpassing 200,000 miles when properly maintained.

Overview of M54B25 Engine Durability

The M54B25’s longevity can be attributed to its robust construction. The engine block is made from cast aluminum alloy, providing a lightweight yet sturdy base, while the use of cast-iron cylinder liners ensures long-term durability of the cylinder walls.

Chain-driven double overhead camshafts contribute to the engine’s reliability, reducing the need for frequent timing belt changes. The engine also benefits from BMW’s VANOS system, which adjusts valve timing for optimal performance but does require attention to maintain.

Factors That Influence Engine Life

Several factors play a crucial role in the longevity of the M54B25 engine:

- Regular Maintenance: Adherence to BMW’s prescribed service intervals is perhaps the most critical factor. Timely oil changes, using the recommended oil grade, and replacing filters are essential to keep the engine running smoothly.

- Quality of Parts: Using high-quality, genuine or OEM-equivalent parts, particularly for crucial components like the VANOS system, water pump, and gaskets, can significantly extend the engine’s lifespan.

- Driving Habits: The engine’s life can be affected by driving habits. Smooth acceleration and avoiding excessive revving before the engine warms up can prevent undue stress on engine components.

- Cooling System Care: The M54B25’s cooling system is complex and requires regular inspection. Prompt replacement of the coolant, thermostat, and water pump, as well as addressing any leaks, is vital to prevent overheating and potential engine damage.

- Addressing Issues Promptly: Small problems can turn into big ones if ignored. For instance, a minor oil leak can lead to low oil levels and increased engine wear if not addressed quickly.

- Environmental Conditions: Engines operated in extreme climates or dusty conditions may require more frequent service to counteract the harsher operating environment.

- Modifications: While the M54B25 can be modified for increased performance, it’s important to note that significant deviations from the stock setup can impact the engine’s reliability. Quality aftermarket support and professional tuning are crucial if modifications are made.

Maintenance and Care

Maintaining the BMW M54B25 engine is crucial for ensuring its longevity and retaining the driving pleasure that BMWs are known for. Adhering to a regular maintenance schedule and following best practices can greatly prolong engine health.

Regular Maintenance Schedule for M54B25

Oil Changes: The lifeblood of the M54B25 engine oil should be replaced every 5,000 to 7,500 miles or every six months, whichever comes first. Using the recommended synthetic oil that meets BMW’s Long-Life-01 specification is crucial.

Cooling System: Refresh the coolant every two years, and inspect the cooling system components regularly. The water pump, thermostat, and expansion tank are known weak points and should be replaced every 60,000 miles, or sooner if signs of wear appear.

Air and Fuel Filters: Replace the air filter every 15,000 to 30,000 miles, more often if driving in dusty conditions. The fuel filter should be replaced every 30,000 miles to maintain fuel flow and engine efficiency.

Spark Plugs and Ignition System: Spark plugs should be replaced every 60,000 miles. Inspect ignition coils and replace them as needed to ensure a strong and consistent spark.

Belts and Pulleys: Inspect accessory belts every 30,000 miles and replace them every 60,000 miles or at the first sign of wear or damage. Tensioners and pulleys should also be inspected and replaced as needed.

Transmission Fluid: For automatic transmissions, fluid changes should occur every 50,000 to 100,000 miles. Manual transmissions typically require less frequent service.

Differentials and Power Steering Fluid: These should be checked and topped up as needed, with a full replacement every 60,000 miles.

Best Practices for Prolonging Engine Health

- Warm-Up the Engine: Allow the engine to warm up gently before driving off, especially in cold weather, to ensure oil has circulated throughout the engine.

- Use Quality Fluids and Parts: Invest in high-quality fluids and genuine or OEM-spec parts to ensure compatibility and longevity.

- Regular Inspections: Visually inspect the engine bay regularly for any signs of leaks, wear, or damage. Early detection of issues can prevent costly repairs down the line.

- Adapt Service Intervals: If you often drive in harsh conditions, consider shortening the maintenance intervals to counteract the increased wear and tear.

- Drive Smoothly: Avoid harsh accelerations and high-revving until the engine reaches operating temperature. Smooth driving habits can reduce strain on engine components.

- Stay Informed: Keep abreast of common issues specific to the M54B25 engine through forums and BMW communities. Knowledge of potential problems can guide proactive maintenance.

- Professional Diagnostics: Have a professional mechanic or a BMW specialist perform regular diagnostics to catch issues that may not be apparent through physical inspection.

Engine Upgrades and Tuning

Performance enthusiasts often seek to enhance the capabilities of the BMW M54B25 engine, an already well-regarded powerplant for its balance and smooth power delivery. Here are some popular performance modifications that can be implemented to improve the engine’s power and efficiency:

Popular Performance Mods for the M54B25

- Cold Air Intake (CAI): Upgrading the factory air intake to a high-flow CAI system, such as those from K&N or AFE, can increase airflow without raising air temperature, leading to improved combustion and slight power gains1.

- ECU Tuning: Custom tunes, like the Shark Injector tune, recalibrate the engine control unit (ECU) to take advantage of higher octane fuel, optimizing the engine’s performance and efficiency. It’s essential to note that once tuned, the engine should consistently run on the specified octane to avoid knocking or damage.

- Exhaust Upgrades: Replacing the stock exhaust system with a performance-oriented setup can reduce backpressure, allowing the engine to breathe better and expel exhaust gases more efficiently. This can lead to gains in both horsepower and torque2.

- Headers: Upgrading to performance headers can significantly enhance exhaust flow, leading to improvements in power, particularly in the mid to high RPM range.

- Supercharger Kits: Centrifugal supercharger kits, like those from AA, VFE, and G Power, can be fitted to the M54 2.5L engine to boost power considerably. Some kits are designed as bolt-on solutions that require minimal tuning, making them a relatively straightforward power upgrade.

- Performance Packages: Companies like Turner Motorsport offer performance packages that are developed in stages for specific BMW models. These packages usually combine various modifications like intake, exhaust, and tuning upgrades to enhance overall performance systematically.

Impact of Modifications on Engine Dynamics

Modifying an engine can significantly change its dynamics. Here’s how the above modifications might affect the M54B25:

- Air Intake and Exhaust: These mods tend to improve engine responsiveness and can lead to a more aggressive engine note. They may also slightly improve fuel economy if the car is driven conservatively.

- ECU Tuning: This can change the engine’s power delivery characteristics, often resulting in more power at higher RPMs. Care must be taken as improper tuning can lead to engine knocking or premature wear.

- Supercharging: This is one of the most significant changes that can be made. It increases the amount of air (and consequently, fuel) entering the engine, greatly increasing power. However, it can also strain engine components and may require supporting upgrades like reinforced internals or an upgraded cooling system to maintain reliability.

For those considering engine upgrades, it’s important to understand that while performance gains are achievable, they should be balanced with considerations for reliability and longevity. Professional installation and tuning, along with regular maintenance, are key to ensuring that performance mods do not lead to costly engine damage down the line.

FAQs on the BMW M54B25 Engine

Life Expectancy of the M54B25 Engine

Q: What is the typical lifespan of the M54B25 engine?

A: The M54B25 engine is known for its durability, with many engines exceeding 200,000 miles when properly maintained. With meticulous care, some have been reported to reach up to 300,000 miles or more.

Common Symptoms and Solutions for Engine Issues

Q: What are the common symptoms indicating issues with the M54B25 engine?

A: Common symptoms include:

- Rough idling or stalling

- Loss of power or poor acceleration

- Overheating

- Unusual noises (knocking, rattling)

- Oil or coolant leaks

- Check engine light activation

Q: What should I do if I encounter these symptoms?

A: Solutions often involve:

- For VANOS issues, replace seals and solenoids.

- Address cooling system leaks by replacing the expansion tank, water pump, and thermostat.

- Seal oil leaks with new gaskets.

- Clean or replace the MAF sensor if faulty.

- For overheating, ensure the cooling system is leak-free and that the coolant mix is correct.

Best Practices for Oil Changes and Maintenance

Q: How often should I change the oil in my M54B25 engine?

A: Oil changes should be performed every 5,000 to 7,500 miles or every six months, whichever comes first, using synthetic oil that meets BMW’s specifications.

Q: What maintenance practices will help prolong the life of my M54B25 engine?

A: Best practices include:

- Regularly check and replace the air filter, fuel filter, and spark plugs according to maintenance schedules.

- Use high-quality fluids and OEM parts.

- Warm up the engine before driving, especially in cold weather.

- Regularly check for and address any leaks or unusual noises.

- Stay informed about common issues specific to the M54B25 and take preemptive action when needed.

- Perform regular diagnostics to catch issues early.