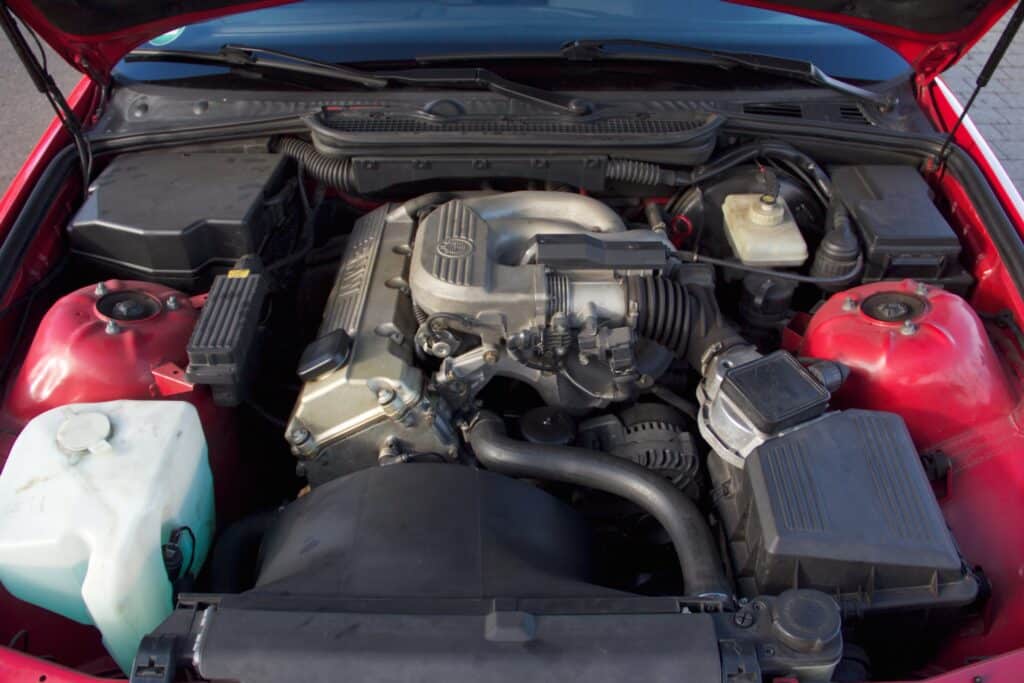

The EA113 engine series began to be established on cars of VAG concern in 2004 year. This series has been developed by engineers who have taken as the basis the 2.0 FSI engine with direct injection of the fuel.

The most important difference is the presence of the turbo. Also on the turbocharged engine cylinder block is made of cast iron rather than aluminum alloy, as at atmospheric.

Also in the construction of the internal combustion of the TFSI engine apply:

- Improved balancing mechanism (two balancing shafts);

- A brand new crankshaft with enlarged persistent tides;

- Reinforced connecting rods;

- The cylinder head (cylinder head) has new camshafts, and valve.

The EA113 2.0 TFSI engine series in its design has hydraulic lifters, a phase shifter on the intake shaft, and a system of direct injection of the fuel. Also, the toothed belt is used, which need to be replaced for every 80-100 thousand km.. Otherwise, thr toothed belt breakage results inevitably in a valve bent.

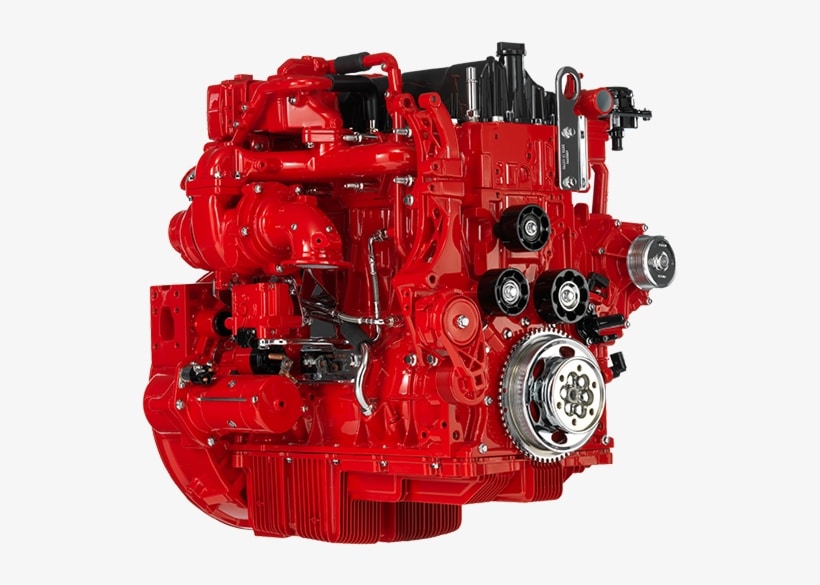

The 2.0 TFSI EA113 series depending on the power used two types of turbines:

- Powerful engine – KKK K04 turbo;

- Weaker engine – Borg Warner K03 turbo.

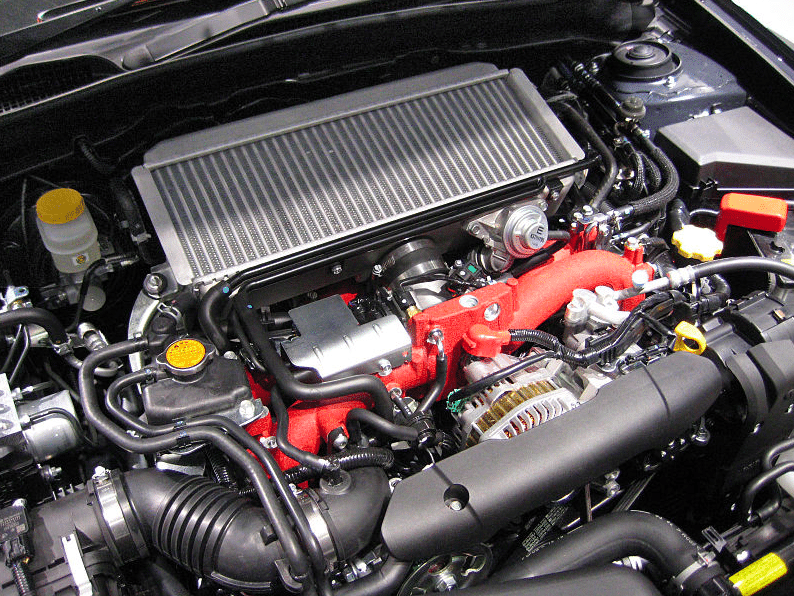

BorgWarner K03 Turbocharger

The 2.0 TFSI had a single water-cooled turbocharger that was integrated with the exhaust manifold into a single unit. For the AXX, BWA, BPY and CAWB engines which produced peak power of 147 kW, a BorgWarner K03 turbocharger provided peak boost pressure of 0.9 bar (13.05 psi). It is understood that the BorgWarner part number for the turbocharger is 5303-970-0105 (OEM part number 06F 145 701D/E/G).

|

|||||||||||||

The speed of the turbine, and hence charge pressure, was controlled by a charge pressure control solenoid valve and vacuum unit, with the latter actuating the wastegate valve via a linkage. When opened, the wastegate valve created a channel for exhaust gases to bypass the turbine.

To prevent the turbocharger from braking too heavily in overrun and between gear changes, an electric air recirculation valve was used. Ordinarily, the pressure would accumulate in the compressor housing during overrun due to the prevailing charge pressure – this pressure build-up would cause the compressor wheel to brake heavily, leading to a reduction in the prevailing charge pressure (turbo drop).

To prevent this from happening, the air recirculation valve was opened by an electric servo motor, creating a bypass channel for compressed air to flow from the compressor wheel back to the suction side of the compressor circuit, thereby keeping the turbine at a constant speed. When the throttle valve was opened, the turbocharger air recirculation valve would close and charge pressure was restored.

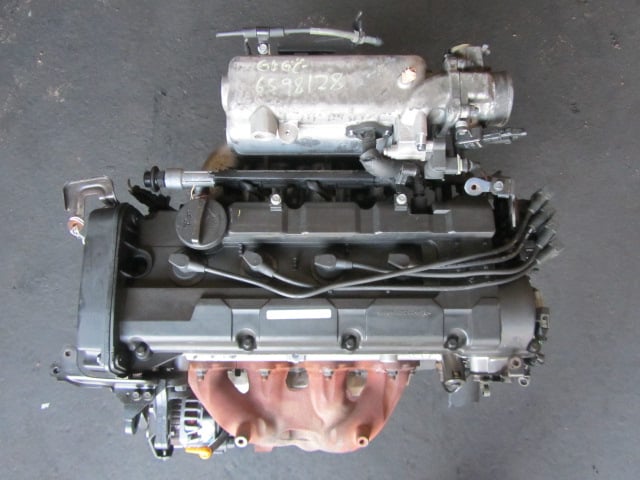

EA113 Engine Specs

| Manufacturer | Plant Audi Hungaria Motor Kft. in Gyor |

| Production years | 2004-present day |

| Cylinder block material | Cast Iron |

| Cylinder head material | Aluminum |

| Fuel type | Gasoline |

| Fuel system | Direct injection |

| Configuration | Inline |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Valvetrain layout | DOHC |

| Bore, mm | 82.5 (3.25) |

| Stroke, mm | 92.8 (3.65 in) |

| Displacement, cc | 1984 (121.1 cu in) |

| Type of internal combustion engine | Four-stroke, turbocharged |

| Compression Ratio | 10.5:1 |

| Power, hp | 170-272 hp (125-200 kW)/4,300-6,000 |

| Torque, lb ft | 199-258 lb-ft (270-350Nm)/1,700-5,000 |

| Engine weight | |

| Firing order | 1-3-4-2 |

| Engine oil grade | 5W-30, 5W-40 |

| Engine Oil Capacity, liters | 4.6 |

| Oil change interval, mile | 12,000 (20,000 km) /12 months |

What Cars Have A VW EA113 Engine?

- Audi A4

- Audi A6

- Volkswagen Jetta

- Volkswagen Golf GTI

- Volkswagen Tiguan

EA113 Engine Modifications

- BPJ – the weakest version of 2.0 TFSI engine for Audi A6 and VW Tiguan. There is one turbocharger.

- AXX, BWA, BWE, BPY – the popular version with power of 200 hp.

- BYD – this engine has reinforced cylinder block, conrods, turbocharger KKK K04 (max pressure is 0.9 bar). Power is 230 hp.

- CDL – analog of BYD, but max boost is higher – 1.2 bar. Power is 256-271 hp.

- BHZ – 265 hp version for Audi S3.

EA113 Engine Problems And Reliability

- High motor oil consumption. It is a common situation with cars, in which mileage is more than average. Often the reason is bad oil rings or valve of crankcase ventilation.

- Knocking, like diesel engine. The reason is wear of the camshaft chain tensioner.

- A car doesn’t accelerate at high rpm. This issue can be fixed by replacement the pusher of the high-pressure fuel pump.

- Loss of power, bad acceleration. The problem lies more often in N249 bypass valve. Many people prefer to remove N249 bypass valve.

In addition, the ignition coil does not live too long. Also, the intake manifold can be periodically polluted. To solve this problem you nedd to cleane it.

The rest of the engine is good, cheerful, likes high-quality gasoline and oil.

When available, gives 200 hp and rides very well.

Over time the motor has been replaced by another 2.0-liter turbo engine EA888 series.

Volkswagen 2.0 TFSI Engine Tuning

To increase the engine power up to 250-260 hp you need to have a Stage 1.

If such a power is small for you, then it is necessary to install the intercooler, outlet on 3 ” pipe, cold intake, a more powerful pump, and Stage 2, it will raise the power up to 280-290 hp.

A further increase in capacity can be extended with a new more powerful K04 turbine and injectors from Audi S3, such a configuration gives ~ 350 hp.

Good morning.

I have an Audi A4 2.0T (BWE engine) It has no power!!!

I have replaced both fuel pumps including the cam follower and fuel rail pressure sender. I have cleared the fuel lines, changed the fuel filter and the PRV.

Could the problem be the timing chain being stretched?

Regards Craig