EcoBoost series are turbocharged gasoline motors with direct injection manufactured by Ford. The debut motor of this type was a joint venture of FEV Engineering (Germany) and Mazda (Japan). Ford 2.0-liter and 2.3-liter motors are turbocharged modifications of Mazda L motors.

Motors of this range were created to reach identical efficiency with naturally aspirated motors featuring cylinders with larger capacity, but, simultaneously reducing fuel consumption and emissions.

Basically, the producer asserts that this motor consumes 30% less fuel and is 15% more eco-friendly. Seeing the EcoBoost technology as more affordable and miscellaneous than its hybrid and diesel rivals, Ford applied it for many of its automobiles.

In 2015, Ford presented its 2.0-liter EcoBoost Generation Two along with the 2.3-liter variant, the largest 4-cylinder motor of the range and the strongest one. In 2015, the 2.3-liter I4 turbocharged motor appeared. Initially, it was employed for the 2015 Lincoln MKC crossover, and the next year, it was utilized for the Ford Explorer and 350 hp Ford Focus RS.

However, EcoBoost reached popularity thanks to the Ford Mustang, which produced 310 horsepower and had a torque of 320 lb/ft (434 Nm). To the point, Mustang SVO, released in the mid-80s, was the last automobile of the brand, keeping a 4-cylinder motor with turbocharging.

Substantially, the EcoBoost with 2.3-liter displacement was built on the framework of the 2.0-liter EcoBoost Generation Two and is often denominated a “stroker”. Though these motors are manufactured at the same plant in Valencia (Spain), the 2.3-liter modification was strengthened to cope with greater power and have better endurance.

Ford 2.3 Ecoboost specs

| Manufacturer | Valencia Engine Plant, Valencia, Spain; Cleveland Engine Plant, Ohio, the USA |

| Production years | 2015-present |

| Fuel type | Gasoline |

| Fuel system | Direct fuel injection |

| Configuration | Inline |

| Cylinder block material | Aluminum |

| Cylinder head material | Aluminum |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Valvetrain layout | DOHC |

| Bore, mm | 87.5 (3.43 in) |

| Stroke, mm | 94.0 (3.70 in) |

| Displacement, cc | 2,264 cc (138.2 cu in) |

| Type of internal combustion engine | Four-stroke, turbocharged |

| Compression Ratio | 9.5:1 |

| Power, hp | 280-350 hp (209-261 kW)/ 5,500-5,600 |

| Torque, lb ft | 305-350 ft lb (414-475 Nm)/ 2,750-3,200 |

| Firing order | 1-3-4-2 |

| Engine oil | 5W-30 |

| Engine Oil Capacity, liter | 5.4 l (5.7 qt) |

| Recommended Fuel | Regular Unleaded (87 Octane) |

| Oil change interval, mile | 9,000 (15,000 km) or 12 month |

| Spark plug gap | 0.028 in (0.7 mm) – 0.031 in (0.8 mm) |

2.3 EcoBoost Part Numbers

| Component | Part Number |

| Air filter element | FA-1918 |

| Oil filter | FL-910-S |

| Battery | BXT-96R-590 |

| Spark plugs | SP-537 |

| Transmission filter | FT-188 |

| Cabin air filter | FP-78 |

| Windshield wiper blade | WW-1964 (passenger side) WW-2160 (driver side) |

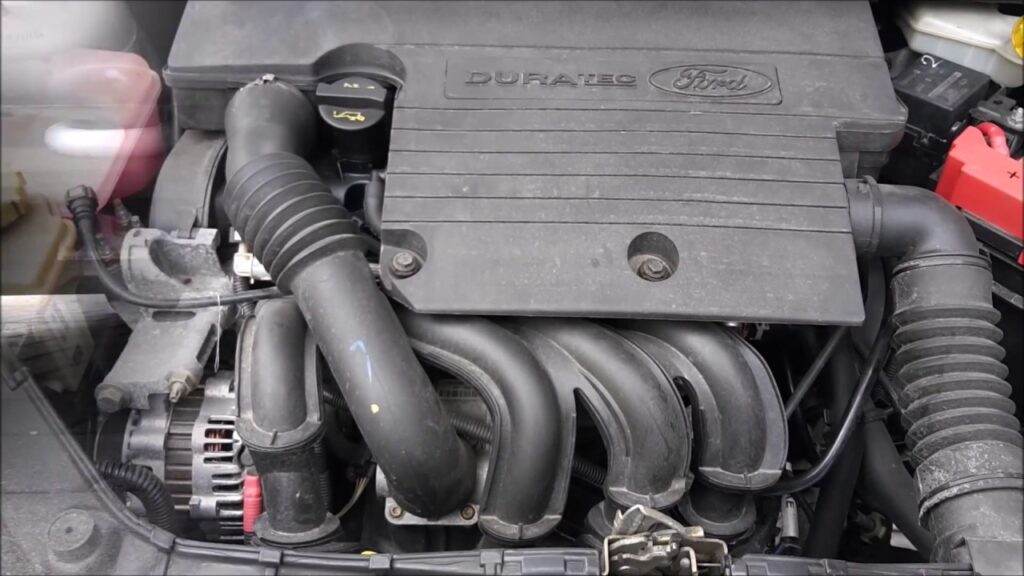

This motor keeps an aluminum cylinder block featuring a die-cast open deck. Having the identical bore size and deck height to 2.0-liter EcoBoost, the block of the 2.3l Ecoboost variation keeps larger oil and cooling passages plus a structural ladder frame (fortifying ribs formed around the cylinders), comprising integrated main bearing caps.

Fresh forged 4340 steel crankshaft featuring 96 mm stroke (compared to 83.1 mm stroke in the 2.0-liter motor) allowed for increasing the capacity. Besides, it gained shorter forged steel connecting rods plus lightweight pistons having steel piston ring carriers plus floating pins.

More efficient lubrication and reduced friction are achieved thanks to updated pistons with low-friction skirt cover and fewer amount of oil drainage ports. Oil, which is spread by the block by special oil jets, cools the cylinder underside. The motor bottom comprises an oil pump controlled by a chain, balance shaft plus die-cast deep-sump aluminum oil pan featuring a baffling surface for oil slosh prevention and oil delivery maintenance under active driving.

An aluminum cylinder head, located on the block upside, keeps 4 valves, 1 GDI fuel injector, and spark plug for each cylinder, and 2 double overhead camshafts controlled by a chain. The structure of the cylinder head supplies the exhaust manifold with 3 high-flow ports for the updated twin-scroll IWG turbocharger. While the 2.0-liter motor has 28 mm exhaust valves, its bigger version contains ones of 30 mm. The intake valves are 32.5 mm. High-efficiency materials were utilized for valve seats.

Being managed by Ford’s Twin Independent Variable Cam Timing system, also called Ti-VCT, camshafts got a higher lift along with better duration. Simultaneously, the exhaust camshaft ensures the functioning of the high-pressure fuel pump (cam-driven fuel pump or CDFP).

2.3 EcoBoost received a modernized plastic intake manifold with a bigger volume and a throttle body of bigger diameter. A twin-scroll turbocharger provides an immediate boost as soon as it’s necessary. Additionally, it grants a flat torque curve much faster than a classic turbocharger. Consequently, upgraded intake details provide more power and faster acceleration reaction, producing less emission, improving turbine performance plus reducing turbo delays.

We recommend Motorcraft replacement parts available at your Ford dealer or at fordparts.com for scheduled maintenance. These parts meet or exceed Ford Motor Company’s specifications and are engineered for your vehicle. The use of other parts may impact vehicle performance, emissions, and durability. Your warranty may be void for any damage related to the use of other parts.

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance specification SAE/USCAR-36.

For spark plug replacement, contact an authorized dealer. Replace the spark plugs at the appropriate intervals.

What Cars Have A 2.3 EcoBoost Engine?

- 270 hp (201 kW; 274 PS) @ 5500 rpm, 310 lb⋅ft (420 N⋅m) @ 3000 rpm on 2019 Ford Ranger

- 280 hp (209 kW; 284 PS) @ 5600 rpm, 310 lb⋅ft (420 N⋅m) @ 3000 rpm on 2016 Ford Explorer

- 285 hp (213 kW; 289 PS) @ 5500 rpm, 305 lb⋅ft (414 N⋅m) @ 2750 rpm on 2015 Lincoln MKC

- 310 hp (231 kW; 314 PS) @ 5500 rpm, 320–350 lb⋅ft (434–475 N⋅m) @ 3000 rpm on 2015 Ford Mustang EcoBoost

- 350 hp (261 kW; 355 PS) @ 6000 rpm, 350 lb⋅ft (475 N⋅m) @ 3200 rpm on 2016-2018 Ford Focus RS and 2016 Zenos E10 R

- 385 hp (287 kW; 390 PS) @ 6000 rpm, 369 lb⋅ft (500 N⋅m) @ 3200 rpm on 2016–2017 VUHL 05 RR

2.3 EcoBoost Engine Oil Check

To check the engine oil level consistently and accurately, do the following:

- Make sure the parking brake is on. Make sure the transmission is in the park (P) or neutral (N).

- Run the engine until it reaches normal operating temperature.

- Make sure that your vehicle is on level ground.

- Switch the engine off and wait 15 minutes for the oil to drain into the oil pan. Checking the engine oil level too soon after you switch the engine off may result in an inaccurate reading.

- Open the hood.

- Remove the dipstick and wipe it with a clean, lint-free cloth. Replace the dipstick and remove it again to check the oil level.

- Replace the dipstick and remove it again to check the oil level.

- Make sure that the oil level is between the maximum and minimum marks. If the oil level is at the minimum mark, add oil immediately.

- If the oil level is correct, replace the dipstick and make sure it is fully seated.

Note: Do not remove the dipstick when the engine is running.

Note: If the oil level is between the maximum and minimum marks, the oil level is acceptable. Do not add oil.

Note: The oil consumption of new engines reaches its normal level after approximately 3,000 mi (5,000 km).

Adding Engine Oil

Do not remove the filler cap when the engine is running.

Do not use supplemental engine oil additives because they are unnecessary and could lead to engine damage that may not be covered by the vehicle Warranty.

Only use oils certified for gasoline engines by the American Petroleum Institute (API). An oil with this trademark symbol conforms to the current engine and emission system protection standards and fuel economy requirements of the International Lubricants Specification Advisory Committee (ILSAC).

To top up the engine oil level do the following:

- Clean the area surrounding the engine oil filler cap before you remove it.

- Remove the engine oil filler cap.

- Turn it counterclockwise and remove it.

- Add engine oil that meets our specifications. You may have to use a funnel to pour the engine oil into the opening.

- Recheck the oil level.

- If the oil level is correct, replace the dipstick and make sure it is fully seated.

- Replace the engine oil filler cap. Turn it clockwise until you feel a strong resistance.

Note: Do not add oil further than the maximum mark. Oil levels above the maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap correctly.

Note: Soak up any spillage with an absorbent cloth immediately.

Oil Change Indicator Reset

Use the information display controls on the steering wheel to reset the oil change indicator.

From the main menu scroll to:

| Message | Action and description |

| Settings | Press the right arrow button, then from this menu scroll to the following message. |

| Vehicle | Press the right arrow button, then from this menu scroll to the following message. |

| Oil Life | Press the right arrow button, then from this menu scroll to the following message. |

| Hold OK to Reset | Press and hold the OK button until the instrument cluster displays the following message. Hold OK to Reset. Reset Successful |

| When the oil change indicator resets the instrument cluster displays 100%. Remaining Life {00}% |

2.3 Ecoboost Twinscroll Turbo

The 2.3-liter motor is the premier motor of the EcoBoost line equipped with a twin-scroll turbocharger. The unique cylinder head keeps a three-port integrated manifold construction, separating inner and outer cylinders into each inlet passage on the turbocharger.

Twin scroll turbochargers guarantee a broad, flat torque, emerging when you stand on it – just the way Mustang fans suppose it to be. Consequently, spool and torque function faster than classic turbochargers while the acceleration reaction is related to the throttle stance. The extra advantages are lower emissions and refined turbine performance.

For better breathing and higher power in Mustang automobiles, the big plenum tapered runner intake manifold plus separated split-pulse twin-scroll turbocharger body were enhanced. Thus, the drivers, who seek for high-performance motors able to consume less fuel, get exactly what they want.

Ford 2.3 EcoBoost Problems and Reliability

2.3 EcoBoost is a heavy-duty turbocharged motor with direct injection, created for drivers, who can’t imagine their life without speed driving. Consequently, the endurance of many details may be shortened in comparison with naturally-aspirated motors.

Leakage of the head gasket is a rather common trouble of these motors in Ford Focus RS vehicles. First, you may notice white exhaust smoke plus excessive coolant consumption. But, afterward, you may face misfiring under load or on a cold start, a sweet odor of the coolant in the exhaust, motor overheating, and loss of cabin heating.

All those malfunctions are a consequence of utilizing the wrong head gasket, the one for the Ford Mustang. Basically, the motor must have special gaskets as 2.3-liter EcoBoost features identical styling but other coolant passages. Besides, bear in mind that head gaskets don’t leak in Mustang motors.

GDI motors, including 2.3 EcoBoost, may face some output loss. The malfunction is accompanied by reduced efficiency and higher fuel use. The reason for that is the concentration of carbon on the back of the intake valves and intake port walls. What’s more, the carbon black layer limits intake airflow and averts intake valves from proper closing. The resolution is to clean the motor from carbon black by initiating the special cleaning process.

I just purchased a 2016 Ford Explorer limited w/ ecoboost:

When the car is initially driven if feels like the transmission may be slipping.It does not transition to each gear smoothly. Is this because of the eco boost?

Hi! What’s the mileage of your Explorer? It doesn’t seem like it’s somehow related to EcoBoost. I’d rather visit my dealership or customer service to check the transmission.

Hi Dan,

I’m looking at Mustang EcoBoost to use as a daily driver.

Read somewhere that this engine will start losing power in 4-5 years and it’s much better to go with GT (5l).

What do you think about keeping Mustang EcoBoost for more than 5 years, how do these 2.3l engines age?

Thanks a lot!

Hi! You know that thing: “No replacement for displacement!”)) That’s a major reason to go with the 5l engine. But, generally, it depends on how do you maintain your engine (and a whole car). Please, understand one thing: The Mustang is a dream car, and first of all, it’s a muscle car, so they were driven aggressively. And after 5 years of this, you want to buy such a car? That’s the first thing.

The second one: comparing these two engines, they have the same set of problems and after 5 years of use it is more like a lottery. Whatever you choose – prepare for problems. But in this case, I would prefer to mess with the 5L engine.

Thanks for your reply!

I’m looking at new Mustangs and always maintain my cars more than required 😉

HI Dan, I periodically use “BerryMen” chem tool in my 17 year old Maxima. Valves are spotless. Would this product work as well in the 2.3 Eco-Boost Engine.

BerryMen, CRC or Seafoam – all are good enough. But cleaner should be designed exactly for Turbo engines. This one is exactly right – https://amzn.to/2VZNlzM

There was some opinions that the spray cleaners may damage the engine. What do you think?

It really does not matter if the outside of your engine is dirty, but it’s important that the inside of your engine is clean. Generally, cleaners are not supposed to harm. As long as you use good gasoline and change the oil regularly – you do not need to use them.

Dan,

I’ve heard that using these chemical cleaners could damage turbos and may void warranty. I have the 2.3 in my explorer. Any experience with turbo damage or was that a ploy to get us to the dealership?

Thanks

It is not allowed Under the Ford Warranty.

I don’t think it could harm: the theory is that If a solid chunk went through a turbo it could POTENTIALLY cause damage but the likely hood of this happening is slim to none. I’ve never seen this in my life…

Your experience may vary but this is my opinion.

Our 2018 explorer 2.3 I4 eco boost is fluttering when around 2000-3000ish rpms. Almost like julting /jumping.

Only 20k miles on it.

And we are on a road trip currently so any ideas? Also seeking out the nearest ford dealer!

Thanks.

I hope your dealer wont say: “It’s a usuall thing, so everything is fine”))

Basically, if it “comes down” after it warms up – I would not be panic. In other case – ypu should check for the errors and visit your local dealer.

I have a new 2019 Ranger with 500 miles on it. So far it is great, 25 MPG locally and lots of power. I generally go gently for the first 1000 but I had to punch it to pass the other day and it was suppressing. Because of the Direct Injection should I install a catch can? If so which one should I use?

Yes, you should install it. I would recommend one from the UPR or Mishimoto.

After looking at my Ranger more and looking on line, It has an oil separator in the PCV line. Does that mean I do not need a Catch Can?

I think you can wait until it starts leaking and then replace it with much more efficient.

What’s your opinion on an oil catch can for the Ecoboost?

I would recommend using cans from the UPR. They are just great and easy to install.

How do you set the timing on this engine there are no marks and the intake camshaft phaser bolt snapped it half. So the phaser spun without moving the camshaft. Replaced all the valves and seals and got everything back together but can’t set timing.

Hi, Dave. Long story short: read here https://cardiagn.com/2019-ranger-engine-2-3l-ecoboost-201kw-273ps/ (from page 41) or try to find a video guide on YouTube.

Hi Dan long story short,,thinking about purchaseing the new Ford bronco it comes with an optional 2.7ecoboost engine,,i ve read that there are issues with the oil pan leakage? Apparently its been an issue for a while,,,

Hello.

Despite multiple repair attempts, the oil leaks keep coming back and cannot be fixed. While the oil leak might stop for a while, even for many months, the oil leak keeps coming back.