The Nissan Juke, with its distinct design and dynamic performance, has cemented its place in the hearts of car enthusiasts around the globe. Its blend of urban agility and sporty flair has made it a favorite among many, becoming almost iconic in its segment.

Key Takeaways:

- Low Oil Level and Potential Coolant Mixing: An insufficient amount of oil can lead to engine knocking. Moreover, frothy oil can indicate coolant contamination, which is a serious concern.

- Worn-out Rod Bearings: These bearings sit between the crankshaft and the piston connecting rods. Their wear can create a gap, leading to a deep knocking sound as the rods clash with the bearings.

- Carbon Deposits in the Combustion Chamber: The buildup of carbon can increase the engine’s compression ratio. This heightened compression can result in detonation and consequently, a knocking noise.

- Use of Incorrect Fuel Octane Rating: Fuel with the wrong octane level may not be compatible with your Juke’s engine requirements, leading to knocking.

- Knock Sensor Malfunction: Modern engines rely on knock sensors to correct knocking. A faulty sensor won’t be able to perform this function, leading to persistent knocking.

- Exhaust System Issues and Manifold Leaks: Anomalies in the exhaust system or leaks in the manifold can produce sounds often mistaken for engine knocking.

- Faulty Timing Chain: A damaged timing chain can be a significant reason for a knock, especially during acceleration.

- Malfunctioning Valve Lifters: These lifters can produce a knocking sound, notably when the vehicle is accelerating.

- Loose Heat Shield Rattle: A detached heat shield can create a rattling noise that is often confused with a typical engine knock.

- Wear between Pistons and Cylinder Walls: Excessive wear in this area can lead to a rattling noise, which can resemble a knock.

This article, however, was sparked by a query from one of our dedicated followers. They encountered a peculiar knocking sound in their 2013 Juke, prompting us to delve deeper and provide guidance not just for them, but for all Juke owners who might face a similar concern.

Possible Causes of the Knocking Sound

Low Oil Level and Potential Coolant Mixing

One of the most straightforward and common causes for a knocking sound in engines, including the Nissan Juke, is a Low Oil Level. Oil serves as a lubricant, ensuring that various engine components operate smoothly without friction.

When the oil level drops below the recommended mark, parts can start rubbing against each other, leading to a knocking sound. Regularly checking and maintaining the correct oil level is essential for the health of your engine.

Further complicating matters is the possibility of Coolant Mixing with the oil. This scenario can arise due to a faulty head gasket or a crack in the engine block, allowing coolant to seep into the oil chamber. When coolant mixes with oil, it can lead to a frothy appearance in the oil, compromising its lubricating properties.

This not only exacerbates the knocking issue but also poses a significant risk to the engine’s overall health, making it crucial to address promptly.

How Can I Check The Oil Level In My Nissan Juke?

Checking the oil level in your Nissan Juke is a straightforward process that every owner should be familiar with. Regularly monitoring your engine oil ensures the longevity and efficient operation of your engine. Here’s a step-by-step guide on how to check the oil level in your Nissan Juke:

Materials Needed:

- Clean cloth or paper towel

- Gloves (optional)

- Safety goggles (optional)

Steps to Check the Oil Level:

- Ensure a Level Ground: Before checking the oil level, park your Nissan Juke on level ground to get an accurate reading. This is crucial for an accurate measurement.

- Wait for the Engine to Cool: It’s best to check the oil level when the engine is cool. If you’ve just been driving, wait for at least 10 minutes to allow the oil to settle back into the oil pan.

- Open the Hood: Pull the hood release lever (usually located under the dashboard on the driver’s side). After the initial release, there might be a secondary latch to lift or push to fully open the hood.

- Locate the Dipstick: The dipstick is a long piece of metal with a handle, typically colored (often yellow) for easy identification. It’s generally located near the front of the engine.

- Remove and Clean the Dipstick: Pull the dipstick out of its tube and wipe off the oil using the clean cloth or paper towel. This step ensures you get an accurate reading.

- Re-insert the Dipstick: Fully insert the dipstick back into the tube, making sure it’s properly seated.

- Pull Out and Read: Remove the dipstick again and look at the oil level in relation to the marks at the end of the stick. There should be two marks (or holes/lines), indicating “MIN” (or “L” for Low) and “MAX” (or “H” for High). The oil should ideally be between these two marks. If it’s close to or below the “MIN” mark, you’ll need to add oil.

- Check Oil Condition: While checking the level, also observe the oil’s color and consistency. Fresh oil is typically amber and becomes darker over time. If the oil looks dirty, gritty, or too thick, consider changing it. Frothy or milky oil might indicate coolant contamination, which requires immediate attention.

- Re-insert the Dipstick: Once done, make sure to properly seat the dipstick back in its tube to prevent contaminants from entering and to maintain proper engine pressure.

- Close the Hood: Make sure to securely close the hood to prevent it from accidentally opening while driving.

Note: If your oil is low frequently or you notice significant drops in levels between regular checks, it may indicate a leak or another issue that should be addressed by a professional mechanic.

Regularly checking your Nissan Juke’s oil level and condition will ensure your engine remains in top shape, potentially preventing costly future repairs.

Worn-out Rod Bearings

Worn-out Rod Bearings are another significant culprit behind the knocking sounds in engines, including in the Nissan Juke. The rod bearings play a crucial role in your engine’s operation.

Positioned between the piston connecting rods and the crankshaft, they provide a smooth surface for the rods to glide on as the crankshaft rotates. Over time and with continuous use, these bearings can wear out or get damaged.

When rod bearings begin to wear out, the once snug fit between the connecting rod and the crankshaft starts to loosen. This increasing gap leads to the connecting rods striking against other parts during the engine’s rotation, resulting in the distinct knocking sound.

If left unchecked, worn-out rod bearings can lead to severe engine damage, emphasizing the importance of timely diagnosis and replacement.

How Do I Know If The Rod Bearings In My Engine Are Worn Out?

Rod bearings play a critical role in an engine’s operation, acting as a buffer between the connecting rods and the crankshaft. When they begin to wear out, it can result in significant engine damage if not addressed promptly. Here are some signs and symptoms that might indicate your rod bearings are worn out:

- Knocking Noises:

- The most common sign of a failing rod bearing is a knocking sound that emanates from the engine. This noise intensifies as you accelerate and can resemble a deep thumping.

- As the bearing wears out further, the knocking becomes louder and more consistent, even at idle.

- Reduced Oil Pressure:

- Worn rod bearings can cause a decrease in oil pressure. Most modern cars come equipped with an oil pressure gauge or warning light. If you notice decreased oil pressure or a warning light, it could indicate worn bearings, among other issues.

- Metal Flakes in Engine Oil:

- When changing the oil or checking the oil level, you may observe small metal flakes or shavings. This is a sign of internal engine components wearing down, potentially the bearings.

- Increased Vibration:

- As the bearings wear out, they might cause increased engine vibration felt through the vehicle’s floor, steering wheel, or seats.

- Decreased Engine Performance:

- Worn rod bearings might cause a noticeable decrease in engine performance. This can manifest as reduced power, poor throttle response, or a rough idle.

- Check Engine Light:

- While the check engine light can be triggered by numerous issues, severe bearing wear or damage can cause misfires or other issues that trigger the light.

What to do if you suspect worn rod bearings

- Immediate Attention: If you suspect your rod bearings are worn, avoid driving the vehicle and seek immediate attention. Driving with bad rod bearings can lead to catastrophic engine damage.

- Professional Diagnosis: A mechanic can use specialized tools, like a mechanic’s stethoscope, to pinpoint the exact source of noises. Additionally, an oil analysis can be done to check for excessive metal content.

- Cost Consideration: Depending on the severity of the wear, the engine might need a bearing replacement or a complete rebuild. Both procedures can be labor-intensive and expensive.

- Preventative Maintenance: Regular oil changes with high-quality oil, ensuring the oil level is maintained, and addressing any unusual engine noises or behaviors promptly can extend the life of rod bearings and prevent excessive wear.

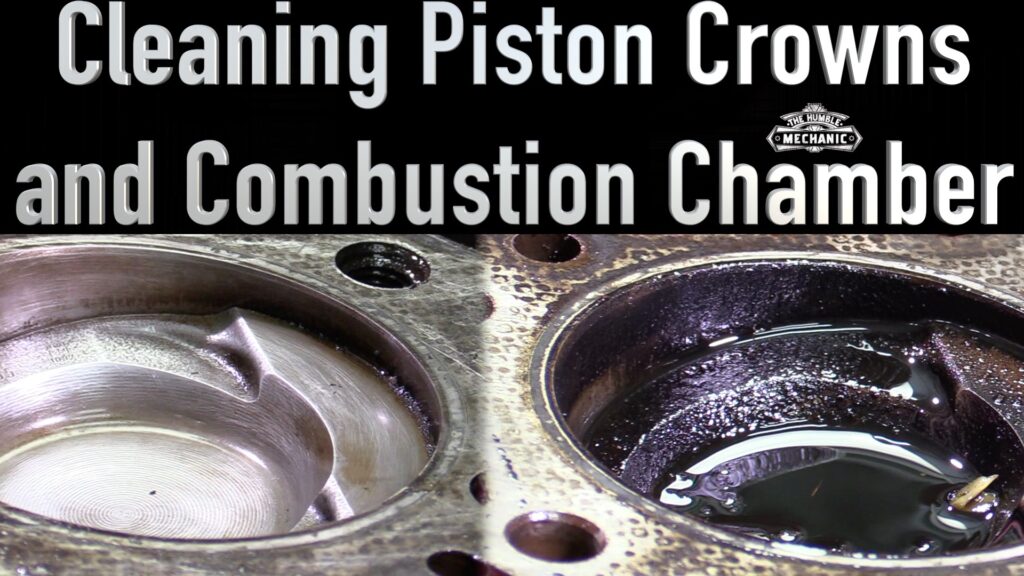

Carbon Deposits in the Combustion Chamber

Carbon Deposits in the Combustion Chamber can be a less obvious but equally troubling cause for knocking sounds in vehicles like the Nissan Juke. The combustion chamber is where the magic happens – it’s where fuel and air mix, ignite and produce the energy that powers your car.

However, over time, residues from fuel combustion can accumulate and form carbon deposits on the chamber’s walls, piston tops, and even the valves.

These carbon deposits have a couple of significant impacts:

- Increased Compression Ratio: The accumulation of carbon effectively reduces the volume of the combustion chamber. This increase in the compression ratio can lead to abnormal combustion patterns, commonly known as “knocking” or “pinging”.

- Hot Spots Formation: Carbon deposits can retain heat and create localized “hot spots.” These hot spots can pre-ignite the air-fuel mixture before the spark plug does its job, leading to premature combustion, which manifests as a knocking sound.

Regular engine maintenance, using high-quality fuel, and occasionally employing fuel additives or cleaners can help prevent excessive carbon buildup and the associated knocking issues.

What Are The Symptoms Of Carbon Deposits In The Combustion Chamber?

Carbon deposits in the combustion chamber form due to the incomplete combustion of fuel and oil residue. Over time, these deposits can affect the efficiency and performance of the engine. Here are some symptoms and problems associated with carbon buildup in the combustion chamber:

- Knocking or Pinging:

- Carbon deposits can effectively raise the compression ratio of the combustion chamber. This increased compression can lead to pre-ignition (also known as knock or ping), especially when using lower octane fuel.

- Reduced Fuel Efficiency:

- Carbon deposits can absorb fuel, leading to its incomplete combustion and, consequently, reduced fuel efficiency.

- Rough Idle:

- Carbon buildup can lead to uneven compression across cylinders or disrupt the normal airflow, causing the engine to idle roughly.

- Cold Start Issues:

- Deposits can cause the spark plug to foul, making it harder for the engine to start, especially in cold conditions.

- Decreased Power and Performance:

- Carbon deposits can reduce the volume of the combustion chamber, thereby decreasing the power output. They can also disrupt the airflow, leading to less efficient combustion.

- Check Engine Light:

- Severe carbon buildup can lead to misfires, causing the check engine light to illuminate.

- Increased Emissions:

- Incomplete combustion due to carbon deposits can lead to increased hydrocarbon emissions, potentially causing the vehicle to fail emission tests.

- Shortened Spark Plug Lifespan:

- Carbon deposits can accumulate on spark plugs, leading to fouling and a shortened lifespan.

- Engine Overheating:

- Carbon is an insulator. If there’s excessive carbon buildup in the combustion chamber, it can cause the engine to retain more heat, leading to overheating.

- Sticking Valves:

- In some cases, carbon deposits can cause the intake or exhaust valves to stick, particularly if the buildup extends to the valve seats.

Preventing and Treating Carbon Deposits:

- Regular Maintenance: Regular oil changes and using high-quality engine oil can help reduce the potential for carbon buildup.

- High-Quality Fuel: Using top-tier gasoline with cleaning agents (detergents) can help prevent carbon deposits. Also, occasionally using a higher octane fuel can help reduce knocking.

- Fuel Additives: There are various fuel additives available in the market designed to help clean carbon deposits in the combustion chamber and fuel system.

- Driving Habits: Periodically driving at highway speeds can help “blow out” carbon deposits, a phenomenon sometimes called the “Italian tune-up”.

- Professional Cleaning: If the problem is severe, consider a professional carbon cleaning service, such as a fuel induction service or walnut blasting (for certain engines).

Use of Incorrect Fuel Octane Rating

The Use of Incorrect Fuel Octane Rating is a commonly overlooked yet significant factor contributing to the knocking sound in engines, including the Nissan Juke.

- Understanding Octane Rating: The octane rating of fuel denotes its resistance to premature ignition or “knocking”. Higher octane fuel is less prone to pre-ignition, making it suitable for high-performance engines or engines with higher compression ratios.

- Detonation and Pre-Ignition: When fuel with a lower octane rating than recommended by the manufacturer is used, it can ignite prematurely due to the engine’s heat or pressure, even before the spark plug fires. This premature ignition, known as detonation or pre-ignition, leads to a sharp knocking or pinging sound. Continual detonation can be harmful to the engine, causing damage to the pistons and cylinder walls over time.

- Check Your Manual: Always refer to the vehicle’s owner’s manual for the recommended octane rating. Using the correct octane fuel ensures optimal performance, efficiency, and longevity of the engine.

- Potential Solutions: If you’ve inadvertently filled your tank with a lower octane fuel, consider adding an octane booster, available at automotive stores, or diluting the low octane fuel by filling the rest of the tank with a higher octane fuel.

Always being mindful of the fuel you’re using and ensuring it aligns with the manufacturer’s recommendation can prevent knocking issues and prolong the health of your engine.

How Can I Determine If I Am Using The Wrong Octane Fuel?

The octane rating of fuel denotes its resistance to knocking or pinging during combustion. Using the wrong octane fuel, especially one lower than the manufacturer’s recommendation, can adversely affect engine performance and could even cause damage over time. Here’s how you can determine if you’re using the wrong octane fuel for your vehicle:

- Engine Knocking or Pinging:

- This is the most common symptom. When the octane rating is too low for the engine’s design, the fuel can ignite prematurely, causing a knocking or pinging sound. This sound typically occurs during acceleration or under load.

- Decreased Performance and Efficiency:

- If you notice a reduction in throttle response, power, or overall efficiency, it might be due to the wrong octane fuel. Lower octane fuels can cause the engine’s control module to adjust the timing to prevent knocking, which can reduce performance.

- Check Engine Light:

- Modern vehicles are equipped with knock sensors that detect abnormal combustion. If knocking is persistent, the check engine light might illuminate.

- Decreased Fuel Economy:

- If your vehicle’s fuel consumption suddenly increases without a change in driving conditions or habits, it might be because the engine control module is adjusting the ignition timing to compensate for the wrong octane fuel, leading to decreased fuel economy.

- Rough Idle:

- In some cases, using the wrong octane fuel can result in a rough or uneven idle, especially if it leads to misfires.

Steps to Confirm Wrong Octane Usage:

- Check Your Owner’s Manual:

- Always refer to the vehicle owner’s manual to find out the recommended octane rating for your specific vehicle model.

- Use a Different Fueling Station:

- Sometimes, issues can arise from a specific station’s bad batch of fuel. Try fueling up at a different, reputable station to see if the symptoms persist.

- Change to a Higher Octane Fuel:

- If you suspect that the fuel’s octane rating is causing issues, try filling up with a higher octane fuel next time and monitor if the symptoms reduce or vanish.

- Engine Diagnostic:

- If symptoms persist, consider getting an engine diagnostic. This can help identify issues related to knock sensors, ignition timing, and other engine performance parameters.

- Fuel Additives:

- There are certain fuel additives available in the market that can boost the octane rating of your fuel. While this is more of a temporary solution, it can be useful to confirm if octane rating is the issue.

- Consistent Fueling Habits:

- If you’ve recently switched from consistently using premium fuel to regular (or vice versa) and notice changes in engine behavior, it could indicate the octane difference’s impact.

Knock Sensor Malfunction

The Knock Sensor Malfunction is an integral part of modern engine management systems, playing a pivotal role in preserving engine health and optimizing performance.

Here’s how it can contribute to knocking sounds in the Nissan Juke and its significance:

- Role of the Knock Sensor: The primary function of a knock sensor is to detect vibrations or sounds indicative of detonation or “knocking” within the engine. When these abnormal combustion patterns occur, the knock sensor sends signals to the engine control module (ECM) to make real-time adjustments. These adjustments can include altering the ignition timing or changing the fuel-air mixture to prevent further knocking.

- Malfunction Consequences: If the knock sensor is faulty or malfunctions, it might not detect and correct the knocking in time or might incorrectly signal the presence of a knock when there isn’t one. In both scenarios, the engine might run sub-optimally, leading to reduced performance, decreased fuel efficiency, and potentially causing engine damage over time.

- Symptoms: Besides the evident knocking sound, other indicators of a malfunctioning knock sensor include decreased acceleration, a check engine light on the dashboard, or poorer fuel efficiency.

- Addressing the Issue: If you suspect a knock sensor issue, it’s crucial to have it checked and replaced if necessary. While the sensor itself might not be overly expensive, neglecting its malfunction can lead to costlier repairs down the line due to potential engine damage.

The knock sensor acts as the engine’s early warning system against harmful detonation. Ensuring its proper functionality is paramount for the engine’s optimal operation and longevity.

Exhaust System Issues and Manifold Leaks

Exhaust System Issues and Manifold Leaks are vital to consider when diagnosing a knocking sound in vehicles, including the Nissan Juke. The exhaust system, while primarily designed to safely channel out combustion gases, can be a source of unsettling noises when problems arise.

- Exhaust System Overview: The exhaust system consists of multiple components, including the exhaust manifold, catalytic converter, resonator, muffler, and exhaust pipes. Each of these components is sealed and interconnected to ensure gases flow out smoothly and silently.

- Exhaust Manifold Leaks: The exhaust manifold collects gases from the engine’s cylinders and directs them into the exhaust system. A leak or crack in the manifold can cause a distinct ticking or knocking sound, especially noticeable during cold starts or acceleration. These leaks can develop due to thermal stress, corrosion, or physical damage.

- Other Exhaust System Issues: Loose or broken exhaust mounts can cause parts of the system to knock against the car’s underbody. Similarly, a damaged muffler or resonator might emit louder-than-usual noises. Occasionally, foreign objects or debris might get trapped within the exhaust system, causing rattling sounds.

- Potential Risks: Beyond the noise annoyance, exhaust system issues can lead to decreased engine performance, reduced fuel efficiency, and the potential release of harmful gases into the cabin. Carbon monoxide, a byproduct of combustion, is particularly concerning if there’s a leak, as it’s a colorless, odorless, and toxic gas.

- Diagnosis and Repair: If you suspect exhaust system issues or manifold leaks, it’s best to have your vehicle inspected by a professional mechanic. They can identify the source of the noise and recommend appropriate repairs. Addressing these issues promptly not only resolves the knocking sound but also ensures a safe driving environment.

While the exhaust system might be an overlooked source of knocking sounds, it’s crucial to diagnose and address potential issues to ensure both vehicle performance and passenger safety.

Faulty Timing Chain

A Faulty Timing Chain is a critical component in many internal combustion engines, including the Nissan Juke. If not functioning correctly, it can be a leading cause of the knocking sound that concerns many vehicle owners.

- Function of the Timing Chain: The timing chain’s primary role is to synchronize the crankshaft’s rotation with the camshaft(s), ensuring that the engine’s valves open and close at the precise times during each cylinder’s intake and exhaust strokes. This synchronization is crucial for the engine to operate efficiently.

- Signs of a Faulty Timing Chain: When the timing chain starts to wear out or stretch, it may not maintain accurate synchronization. This can lead to:

- Knocking or rattling sounds, especially during startup or acceleration.

- Rough idling or reduced engine performance.

- The engine misfiring or even failing to start.

- Check engine light illuminating.

- Causes of Timing Chain Issues:

- Natural Wear and Tear: Over time, the metal links in the chain can stretch, affecting its timing capabilities.

- Insufficient Lubrication: If the engine oil isn’t regularly changed or is of low quality, it can lead to premature wear of the timing chain.

- Faulty Chain Tensioners or Guides: These components keep the chain tight and aligned. If they fail, the chain can become slack or misaligned.

- Potential Damage: Ignoring a faulty timing chain can lead to catastrophic engine damage. If the chain breaks or skips a tooth, the engine’s valves can collide with the pistons, resulting in expensive repairs or even a complete engine replacement.

- Recommendation for Resolution: If you suspect a problem with the timing chain, seek professional assistance immediately. Addressing the issue early can prevent more severe and costly damages. Regular maintenance, including timely oil changes and using quality engine oil, can also extend the life of the timing chain and associated components.

The timing chain is the rhythmic heart of your engine. Ensuring its proper function is essential for the smooth and efficient operation of your Nissan Juke.

Malfunctioning Valve Lifters

Malfunctioning Valve Lifters, also known as hydraulic lifters or tappets, play a pivotal role in maintaining the efficient functioning of an engine.

When these components start to fail, they can be a source of the distressing knocking or ticking sounds in vehicles, including the Nissan Juke.

- Function of Valve Lifters: Valve lifters are responsible for maintaining zero valve clearance in the valve train. This means they help ensure that the valves open and close smoothly, without any slack that could cause noises or reduce engine efficiency.

- Signs of Malfunctioning Valve Lifters: When these lifters aren’t operating as they should, the following symptoms might emerge:

- A distinct ticking or tapping sound, often pronounced during a cold start and may diminish as the engine warms up.

- The noise intensifying during acceleration.

- Possible reduction in engine performance.

- Causes of Lifter Malfunctions:

- Age and Wear: Over time, lifters can wear out due to constant motion and high pressures.

- Sludge Build-Up: Infrequent oil changes or the use of low-quality oil can lead to sludge build-up, affecting lifter performance.

- Insufficient Lubrication: Low oil levels or poor-quality oil can starve lifters of necessary lubrication, leading to premature wear.

- Failed Lifter Components: The internal components of a hydraulic lifter can malfunction, preventing it from maintaining proper valve clearance.

- Potential Consequences: If malfunctioning lifters are ignored, it can lead to:

- Further wear of other valve train components, such as the camshaft.

- Reduced engine efficiency and performance.

- Potential engine damage if left unchecked for extended periods.

- Recommendation for Resolution: If you suspect an issue with the valve lifters:

- Check the engine oil level and quality. Consider an oil change with a quality oil recommended for your vehicle.

- Additives are available that can help clean and lubricate the valve train, potentially alleviating lifter noise.

- If the issue persists, seek the expertise of a professional mechanic. In some cases, malfunctioning lifters might need replacement.

While valve lifters are small components, they hold significant responsibility in maintaining engine rhythm and performance. Regular maintenance and timely interventions can prevent complications arising from malfunctioning lifters in your Nissan Juke.

Loose Heat Shield Rattle

Loose Heat Shield Rattle is a common yet often overlooked cause of unsettling noises in many vehicles, including the Nissan Juke. While it may not pose as significant a threat as some other engine-related issues, it’s essential to understand and address the cause to maintain a quiet and comfortable driving experience.

- Function of the Heat Shield: The heat shield is designed to protect various parts of a vehicle, especially the undercarriage, from the high temperatures produced by the exhaust system. By doing so, it prevents heat-sensitive components from being damaged and also protects the car’s interior from excessive heat.

- Signs of a Loose Heat Shield: The most indicative sign is:

- A distinct rattling or metallic vibration noise, especially noticeable during startup, acceleration, or when driving on uneven roads.

- Causes of Heat Shield Looseness:

- Age and Corrosion: Over time, the metal clamps or brackets holding the shield in place can corrode, weaken, and break.

- Physical Impact: Driving over debris, rough terrains, or bumps might dislodge or damage the shield or its attachments.

- Improper Servicing: If the shield was removed and not properly reattached during maintenance or repairs, it can come loose.

- Potential Risks:

- While a rattling heat shield is more of an annoyance than a hazard, ignoring it can lead to the shield getting further damaged or detached, potentially leading to other complications.

- If the shield comes in direct contact with the exhaust, it can amplify the heat and affect nearby components.

- Recommendation for Resolution:

- Conduct a visual inspection: With the vehicle safely elevated, look beneath to identify any loose or damaged shields.

- Tightening: If the shield is slightly loose, tightening the clamps or fasteners can resolve the issue.

- Replacement: Severely damaged or corroded shields and fasteners should be replaced to ensure proper protection.

- Temporary Fixes: While not recommended as a long-term solution, some drivers use large hose clamps to secure a loose shield temporarily until a proper fix can be done.

A loose heat shield might seem like a minor annoyance, but ensuring it’s secure and intact contributes to the overall health and performance of your Nissan Juke. Regular inspections and timely repairs can help mitigate the risks associated with a malfunctioning heat shield.

Wear between Pistons and Cylinder Walls

Wear between Pistons and Cylinder Walls, often referred to as “piston slap”, is a more intricate mechanical concern that can manifest as a knocking or slapping sound in vehicles, including the Nissan Juke.

Understanding this issue is crucial, as it delves into the very heart of an engine’s operation.

- Piston and Cylinder Wall Interaction: Pistons move up and down within the cylinder walls as the engine operates. Proper lubrication and fitment are essential for smooth movement and minimizing wear.

- Signs of Wear or Piston Slap:

- A cold-start knocking sound that generally diminishes as the engine warms up.

- The knocking sound can become more pronounced during acceleration or when under load.

- Causes of Piston Slap:

- Manufacturing Variances: Sometimes, there’s a slight mismatch in size between the piston and the cylinder.

- Wear and Tear: Over time, both the piston and the cylinder wall can wear down, creating a looser fit.

- Inadequate Lubrication: If the engine oil isn’t adequately lubricating the piston-cylinder interface, wear can be accelerated.

- Thermal Expansion: Metals expand with heat. If a piston is slightly loose when cold, the gap might reduce as the engine warms up, explaining the reduction in noise.

- Potential Consequences:

- Reduced Engine Efficiency: The wear can lead to compression loss, affecting the engine’s performance.

- Further Damage: If left unchecked, the continuous slap can exacerbate the wear and potentially damage other components.

- Oil Consumption: Excessive wear can lead to increased oil consumption, as oil slips past the worn piston rings into the combustion chamber.

- Recommendation for Resolution:

- Frequent Oil Changes: Ensure regular oil changes with high-quality oil to minimize wear and provide adequate lubrication.

- Inspection: If piston slap is suspected, a professional inspection is recommended. A mechanic might use a stethoscope to pinpoint the noise or perform a compression test.

- Repair/Replacement: In some severe cases, the only remedy might be to repair or replace the affected pistons and cylinders. However, this can be a costly endeavor.

- Driving Habits: Gentle driving, especially during cold starts, can minimize the impact and progression of the wear.

While piston slap or wear between pistons and cylinder walls might sound alarming, timely interventions, regular maintenance, and gentle driving can mitigate its impact and prolong the lifespan of your Nissan Juke’s engine.

Troubleshooting Steps to Identify the Cause

One of the most crucial first steps in troubleshooting any problem is keen observation. The knocking sound’s nature and when it occurs can provide significant insights into the root cause. Here’s how you should proceed:

- Engine Temperature:

- Cold Engine: If the knock is more prominent when the engine is cold and tends to fade as the engine warms up, this might indicate issues like piston slap. Some metals expand with heat, so a cold engine might have more clearances which can cause knocking.

- Warm Engine: If the knocking sound starts or gets worse once the engine is at its operating temperature, it could be an indication of a more severe internal engine issue, such as worn rod bearings.

- Engine Load Conditions:

- During Acceleration: A knock during acceleration often indicates pre-ignition or detonation issues, which can be due to low octane fuel, carbon buildup, or a faulty knock sensor.

- During Deceleration: This is less common, but if you notice a knocking sound during deceleration, it could point to specific transmission issues or sometimes even in the driveline.

- While Idling: A knocking sound while the engine is idling can be indicative of various problems such as worn engine bearings, faulty pulleys, or even issues outside the engine like a loose exhaust component.

- Driving Conditions:

- Highway vs. City: If the knock is more noticeable during city driving (stop-and-go traffic) but seems to vanish or reduce on the highway, it could indicate temperature-related issues or problems that manifest under variable loads.

- Uphill Driving: Knocking or pinging noises during uphill drives (when the engine is under more strain) can indicate issues with the fuel mixture or octane rating.

- Frequency and Pitch:

- High-pitched or Tinny: This could indicate a problem on the top end of the engine, such as issues with the valve train.

- Deep or Thudding: A deeper sound often points to problems in the lower end of the engine, like worn-out rod bearings.

- Location of the Sound:

- Front, Back, Left, or Right: Localizing the sound can help pinpoint issues. For example, a sound from the front might point to accessory pulleys or belts, while a sound from the rear might indicate exhaust issues.

- Consistency:

- Consistent vs. Intermittent: A consistent knock that keeps pace with engine RPM could be a sign of mechanical failure, while an intermittent knock might be related to irregular combustion or even external factors like loose shields.

By meticulously noting the conditions when the knock occurs and describing its nature, you can provide a mechanic with valuable information to diagnose the issue more accurately. It also aids in DIY troubleshooting, helping you narrow down potential causes and solutions.

Pinpointing the Source of the Knock: Location Identification

Determining the location of the knocking sound within the engine compartment is critical, as it can significantly narrow down potential issues. Here’s a guide on how to pinpoint the source:

- Engine Bay Safety:

- Before attempting any diagnosis, ensure that the engine is switched off, and it’s safe to work around. Use gloves and protective eyewear, especially if the engine is hot.

- Using a Mechanic’s Stethoscope:

- A mechanic’s stethoscope is a valuable tool to help isolate the source of a knock. If you don’t have one, a long screwdriver can serve as a makeshift stethoscope.

- Place the metal end on different parts of the engine and the handle to your ear. The sound will travel through and help you locate the source.

- Top End of the Engine:

- Sounds from the top typically relate to the valve train and might indicate issues like:

- Worn camshaft lobes

- Failing rocker arms or lifters

- Valve timing issues

- Sounds from the top typically relate to the valve train and might indicate issues like:

- Middle of the Engine:

- Knocking sounds originating from the middle of the engine might indicate problems such as:

- Piston slap

- Worn wrist pins

- Cylinder wall wear

- Knocking sounds originating from the middle of the engine might indicate problems such as:

- Bottom End of the Engine:

- Deep knocking sounds from the bottom end usually point to serious issues, like:

- Rod knock from worn-out rod bearings

- Main bearing wear

- Crankshaft issues

- Deep knocking sounds from the bottom end usually point to serious issues, like:

- Outside the Engine:

- Remember, not all knocks are internal to the engine. External components, such as pulleys, belts, and even the exhaust system, can produce knocking sounds. Check for:

- Loose pulleys

- Damaged belts

- Exhaust leaks or loose heat shields

- Remember, not all knocks are internal to the engine. External components, such as pulleys, belts, and even the exhaust system, can produce knocking sounds. Check for:

- Other Locations:

- Transmission: Sometimes, a failing transmission can produce knocking sounds, especially during gear changes.

- Wheel and Brake Area: Worn components in the wheel area, such as a bad CV joint, can also produce knocks, especially when turning.

- Observing from Outside:

- Sometimes, getting out of the car while someone else revs the engine or drives it slowly can help in identifying the location of the knock.

- Using Technology:

- Some advanced automotive diagnostic tools and software can analyze sound patterns to help pinpoint issues. These tools might be available at well-equipped auto repair shops.

- Other Observations:

- Look for other signs that might help in diagnosis. For example, blue smoke from the exhaust might indicate oil burning due to worn piston rings. A metallic smell might indicate an overheating part.

By accurately pinpointing the location of the knock, you’ll have a clearer path to diagnosing and resolving the issue. If you’re unsure, or if the sound indicates a severe internal engine problem, it’s always wise to consult with a professional mechanic.

Checking the Oil Status: Assessing the Oil Level and Its Condition

Regularly checking and maintaining engine oil is pivotal for the longevity and smooth running of your engine. A significant number of engine-related problems arise due to negligence in this area. Here’s a step-by-step guide on how to check the oil status in your vehicle:

- Safety First:

- Ensure the vehicle is on a level surface to get an accurate reading.

- The engine should be off and cool. It’s best to check oil in the morning before starting the car or wait about 10-15 minutes after shutting off a warm engine.

- Gathering Necessary Items:

- You’ll need a clean rag or paper towel.

- Wear gloves to keep your hands clean.

- Locating the Oil Dipstick:

- Open the vehicle’s hood and locate the oil dipstick, usually marked with a yellow or brightly colored handle.

- Checking the Oil Level:

- Pull out the dipstick and wipe it clean with your rag or paper towel.

- Insert the dipstick fully back into its tube and then pull it out again.

- Look at both sides of the dipstick to see where the oil’s film is between the two marks. If the oil is between the two lines or dots, the level is acceptable.

- If the oil is below the minimum mark, you’ll need to add oil immediately. Overfilling, or filling it above the maximum mark, is equally detrimental.

- Assessing Oil Condition:

- Color: New oil has a transparent amber color. Over time, it will get darker, but if it’s thick and black, it’s a sign that you need an oil change.

- Consistency: Rub the oil between your thumb and forefinger. If it leaves a dirty smudge, it might be time for an oil change. If you feel small particles or grit, this could be an indicator of engine wear or contaminants.

- Smell: Oil with a burnt smell indicates overheating or problems with internal components.

- Presence of Froth or Milky Color:

- If you notice a frothy texture or a milky color to the oil, this could be a sign of coolant leaking into the engine oil, indicating a potential head gasket issue or a crack in the engine block.

- Checking the Oil Fill Cap:

- Remove the oil fill cap (usually located on the top of the engine) and inspect underneath. A milky or frothy residue here could also suggest coolant contamination.

- Regular Monitoring:

- Even if everything seems fine, make it a routine to check the oil level and condition at least once a month or before long trips.

Remember, oil not only lubricates but also helps in cooling engine parts, reducing friction, and cleaning impurities. If you’re uncertain about the oil’s condition or if you find contaminants, it’s a good idea to get the vehicle checked by a mechanic and consider an oil and filter change.

Using Diagnostic Tools

Modern vehicles are equipped with intricate electronic systems that constantly monitor the performance and health of your car’s components. One primary way your vehicle communicates a problem is through the “Check Engine” light. However, this indicator is just the tip of the iceberg; to truly understand the underlying issue, diagnostic tools come into play.

- What Are Diagnostic Tools?

- Diagnostic tools, often referred to as OBD-II (On-Board Diagnostics II) scanners, interface with a car’s computer system to extract detailed information about any detected malfunctions.

- Why is Retrieving Diagnostic Codes Crucial?

- Specificity: The check engine light alone doesn’t specify the nature of the problem. Diagnostic codes offer more precise information about the source and nature of the issue.

- Cost-Efficient: Identifying the exact problem can prevent unnecessary repairs, saving time and money.

- Safety: Some issues indicated by the check engine light can be hazardous if not addressed promptly. Retrieving codes can alert you to critical problems that need immediate attention.

- Maintenance Planning: Some codes might point towards parts nearing the end of their life but not yet fully malfunctioned. This can help in planning maintenance and replacements proactively.

- How to Use an OBD-II Scanner:

- Connect: Find the OBD-II port, typically located under the dashboard on the driver’s side. Plug in the scanner.

- Turn On the Vehicle: This powers up the car’s computer system and allows the scanner to communicate with it.

- Retrieve Codes: Follow the scanner’s instructions. Typically, you’ll press a button like “read” or “scan” to retrieve codes.

- Interpret Codes: Once retrieved, the scanner will display specific error codes. These alphanumeric codes can be looked up in a database or manual that provides a description of the issue.

- Professional vs. Basic Scanners:

- Basic Scanners: These are affordable and provide you with error codes but may not offer detailed descriptions or advanced features.

- Professional Scanners: More expensive but come with advanced features like live data streaming, system tests, code definitions, etc.

- What Next After Retrieving the Codes?

- Research: Once you have the codes, look them up online or in a repair manual specific to your vehicle make and model.

- Consultation: If unsure about the meaning or severity of a code, consult with a professional mechanic or dealership.

- Address the Issue: Depending on the identified problem, either fix it yourself or schedule a visit to a mechanic.

- Clearing the Codes:

- After the issue is resolved, the scanner can also be used to clear the codes, turning off the check engine light. However, be cautious; merely clearing the light without addressing the problem is not advisable.

While the check engine light is a valuable initial warning, using diagnostic tools to retrieve specific codes is essential for effective troubleshooting and maintaining the health of your vehicle.

Leveraging Online Resources

Online communities and forums have become invaluable resources for car enthusiasts, owners, and mechanics alike. They offer firsthand experiences, and solutions to common problems, and provide an opportunity to ask questions to a wider audience. For Nissan Juke owners, platforms such as Juke Forums and Nissan Juke Owners Club can serve as treasure troves of information.

- Why Use Online Forums?

- Shared Experience: Real users share real problems (and solutions). These experiences can often mirror your own, offering insights you might not find in official manuals.

- Cost-Efficiency: Before heading to a mechanic, a simple search on these forums might provide a DIY solution or at least give you an understanding of potential repair costs.

- Wide Audience: Post a question and get answers from a diverse group, from everyday drivers to experienced mechanics familiar with the Nissan Juke.

- Navigating the Forums:

- Search Function: Before posting a new question, use the forum’s search function. Chances are, someone has already asked a similar question.

- Join & Introduce Yourself: Being an active member, introducing yourself, and participating in discussions can increase the chances of getting answers to your questions.

- Stay Relevant: Stick to the forum’s theme. If you’re on a Nissan Juke-specific forum, ensure your discussions are relevant to the model.

- Etiquette and Best Practices:

- Be Respectful: Remember that these are communities. Treat others with respect, and avoid confrontational or aggressive behavior.

- Provide Details: When asking for help, be as detailed as possible about your problem. This will help others provide more accurate advice.

- Acknowledge Help: If someone provides useful advice or a solution to your problem, take a moment to thank them.

- Limitations of Online Forums:

- Accuracy: While many forum members are knowledgeable, information accuracy can vary. It’s always a good idea to double-check or seek a second opinion, especially for significant repairs.

- Activity: Some forums or threads might be inactive. Check the dates of the last posts to ensure you’re viewing current information.

- Beyond Troubleshooting:

- Networking: These forums can be a great place to connect with other Nissan Juke enthusiasts, plan meet-ups, or discuss non-mechanical topics related to the vehicle.

- Updates & News: Stay updated on recalls, software updates, or other model-specific news shared by members.

While online forums are an excellent tool in the troubleshooting process, always exercise judgment and caution. Embrace these communities, learn from them, and contribute to the shared knowledge.

The Role of Professional Inspection

There are times when DIY troubleshooting and online forums might not suffice, and seeking a professional’s expertise becomes imperative. Recognizing the right time to get your Nissan Juke inspected by a mechanic can save you from costly repairs in the future.

Moreover, choosing someone familiar with Nissan vehicles can ensure a more accurate and efficient diagnosis.

- Why Opt for a Professional Inspection?

- Complex Issues: Some problems, especially those deep within the engine or electronic systems, may require specialized tools or expertise to diagnose.

- Safety Concerns: If you suspect an issue that might compromise your vehicle’s safety, it’s always best to get a professional opinion.

- Warranty: Some repairs might be covered under warranty, but trying to fix them yourself or going to an unauthorized mechanic could void it.

- Signs It’s Time for a Professional Inspection:

- Persistent Issues: If you’ve tried a DIY fix or followed advice from a forum, but the problem persists, it might be time for a professional look.

- Unidentifiable Noises: If you can’t pinpoint the source or cause of a particular noise, especially after trying the previous troubleshooting steps, a mechanic’s expertise can be invaluable.

- Warning Lights: If your check engine light or any other dashboard warning light is on, a mechanic can retrieve the exact error code, shedding light on the issue.

- Choosing a Mechanic Familiar with Nissan:

- Brand-Specific Knowledge: Every car brand has its unique design and engineering nuances. A mechanic familiar with Nissan will likely recognize common issues with the brand or specific models like the Juke.

- Access to Genuine Parts: Mechanics specializing in a particular brand often have better access to genuine replacement parts.

- Updated Training: Nissan specialists are often more updated with the latest technical training and service bulletins from the manufacturer.

- Questions to Ask Your Mechanic:

- Experience with Nissan Juke: Before handing over your keys, ask about the mechanic’s experience with your specific model.

- Estimates: Always ask for an estimate before any significant repair. This prevents unexpected costs and allows you to compare with other service providers if necessary.

- Warranty on Repairs: Inquire about any warranties or guarantees on the work they’ll perform.

- Building a Relationship:

- Trust & Communication: Like any other professional service, building a trusting relationship with your mechanic is beneficial. It ensures clear communication, and they become familiar with your vehicle’s history.

- Scheduled Maintenance: Regular maintenance visits, even when there’s no apparent issue, can help in early problem detection and prolong your Nissan Juke’s lifespan.

Addressing the Knock Promptly for Safe and Smooth Journeys

Every vehicle, including the Nissan Juke, is a marvel of engineering, designed to function optimally when all its components are in harmony. An unusual knock or any other unfamiliar sound is your car’s way of communicating that something is amiss. Ignoring these signs can lead to more severe, and often more expensive, problems down the line.

Addressing such issues promptly not only ensures the longevity of your vehicle but also guarantees the safety of its occupants. A knock, especially if originating from vital components like the engine or the exhaust system, can signify potential risks that may compromise the car’s overall performance or even lead to sudden malfunctions. In the realm of driving, such unpredictable incidents can have dire consequences.

Furthermore, regular vehicle maintenance goes beyond just addressing immediate concerns. It’s a proactive approach to car care, allowing you to spot potential problems before they escalate. This not only saves on potentially hefty repair bills but also ensures that every drive is as smooth as the one before.

In conclusion, your Nissan Juke is more than just a means of transportation; it’s an investment, a companion, and sometimes an extension of who you are. Treating it with the care it deserves by addressing issues like a knock sound promptly ensures it serves you reliably for years to come.

Always prioritize safety, drive responsibly, and remember that regular maintenance is the cornerstone of a vehicle’s health and longevity. Safe journeys!