Checking tire tread depth is important for several reasons. The tread grips the road, and if it’s not deep enough, the car loses traction and suffers extended braking times. Shallow tread grooves make it harder to control the vehicle in wet weather, and the chance of aquaplaning increases.

Measuring the tread depth as part of regular vehicle maintenance is recommended to ensure safety. The original tread depth of a new tire can vary, and as the tread wears down, a tire with a depth below 1.6 millimeters (2/32 inches) lacks grip and is unsafe for driving.

Tread depth also affects braking performance and the risk of aquaplaning on wet roads. It’s important to check the tread depth regularly and replace tires when necessary to ensure safety and optimal vehicle performance.

Tire tread depth is crucial for various reasons, including maintaining gas mileage, managing inclement weather, passing safety and emissions inspections, and ensuring proper vehicle handling and braking.

The minimum legal limit of tire tread depth is 2/32 of an inch, and many mechanics recommend replacement when the tread depth reaches between 3/32 and 4/32 of an inch, especially in areas with severe climates.

Methods for Checking Tread Depth

Tire tread depth can be checked using various methods, such as tread wear indicators, a tire tread depth gauge, or the penny test. Inspecting tires for other signs of wear, such as cracks, bulges, or uneven wear, is also important.

Ensuring your vehicle’s tires have adequate tread depth is crucial for safe driving. The tread on your tires is what provides the necessary grip on the road, especially in adverse weather conditions.

Here are three reliable methods to check the tread depth of your tires:

Tread Wear Indicators: Built-in Guides for Tire Replacement

Tread wear indicators, also known as wear bars, are small raised bars that run between the tire’s tread grooves. Once your tire’s tread is worn down to these bars, it’s time to replace the tire.

These indicators are strategically placed at various locations around the tire to provide a quick visual indication of tread wear. To locate them, look for the small horizontal bars that appear within the tire tread grooves.

These bars will become flush with the tire’s tread pattern when the depth reaches 2/32 of an inch (1.6 millimeters), signaling that the tire no longer meets legal safety standards and should be replaced.

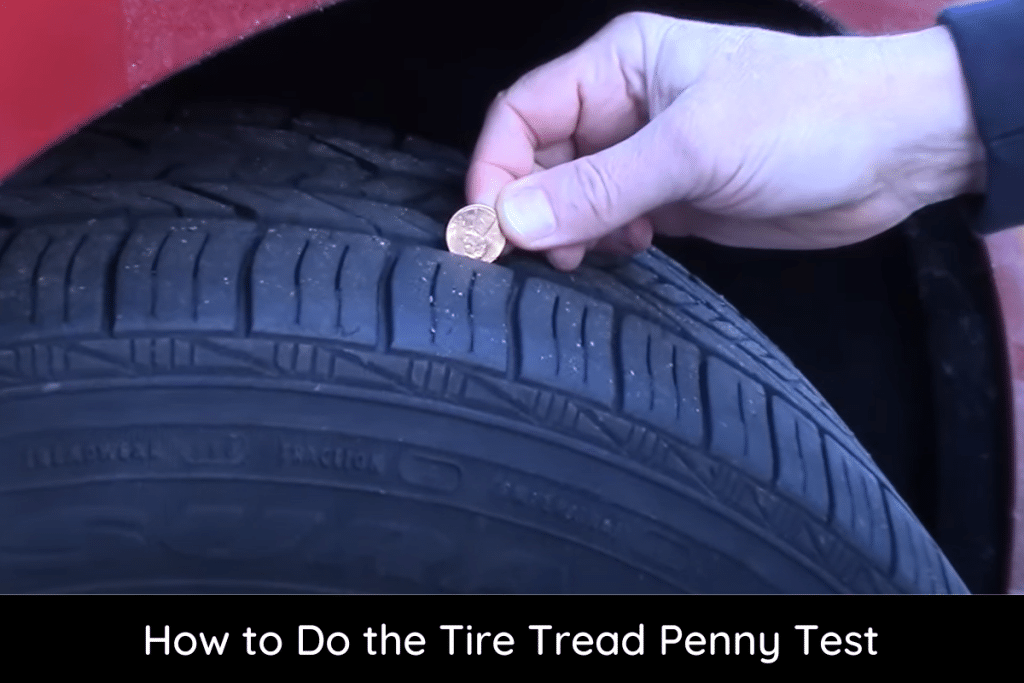

The Penny Test: A Simple Technique for Tread Depth Check

The Penny Test is a quick and easy way to check if your tire tread depth is above the minimum legal limit of 2/32 of an inch. Here’s how to do it:

- Find a Penny: Grab a penny and hold it so Lincoln’s head faces down.

- Insert the Penny: Place the penny into a tread groove on your tire.

- Check Lincoln’s Head: If part of Lincoln’s head is covered by the tread, you have more than 2/32 of an inch of tread depth remaining. If you can see his entire head, it’s time to consider replacing your tire, as it’s below the legal limit.

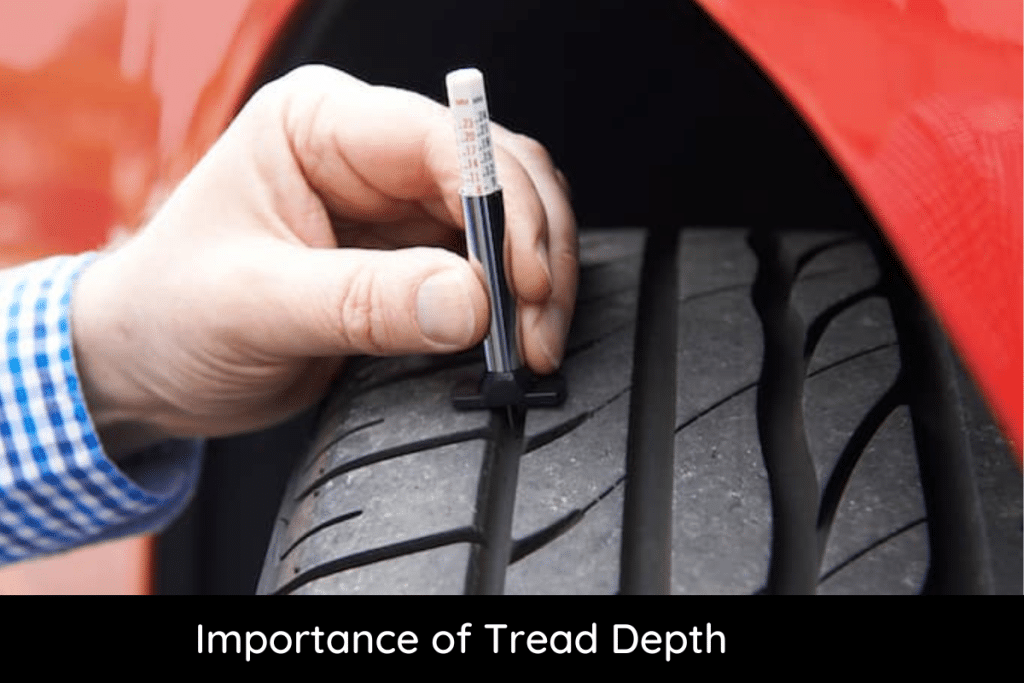

Tread Depth Gauge: Precise Measurement for Tread Depth

For those seeking more accuracy, a tread depth gauge is the tool for the job. These gauges are inexpensive and accurately measure your tire’s tread depth in 32nds of an inch or millimeters. Here’s how to use one:

- Zero the Gauge: Make sure the gauge is set to zero. If you’re using a digital gauge, turn it on.

- Insert the Probe: Find a spot in the tire tread and insert the gauge’s probe until the base sits flush against the tread block.

- Read the Measurement: Read the measurement on the gauge. A reading of less than 2/32 of an inch (1.6 millimeters) means your tire is legally worn out and needs to be replaced.

Importance of Maintaining Proper Tire Pressure

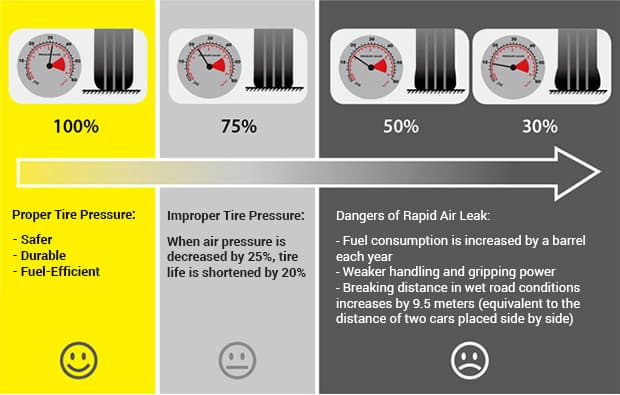

Maintaining the correct tire pressure is not just about following manufacturer recommendations; it’s a critical aspect of vehicle safety, efficiency, and the overall cost of driving.

Here’s why it’s so important:

Safety: The Foundation of Vehicle Handling

- Vehicle Handling: Proper tire pressure is essential for optimal vehicle handling. Under-inflated tires can lead to decreased steering precision and longer response times, while over-inflated tires might reduce the tire’s contact area with the road, leading to a loss in traction. Both scenarios can significantly affect the vehicle’s handling, making maneuvering more difficult in emergencies.

- Braking Distance: The pressure in your tires directly influences braking efficiency. Under-inflated tires can increase braking distance, especially on wet roads, because of reduced traction. Ensuring your tires are properly inflated helps maintain the shortest possible braking distance, keeping you and others safer on the road.

- Risk of Tire Failure: Incorrect tire pressure, be it too high or too low, significantly increases the risk of tire failure. Over-inflated tires are more susceptible to road debris and potholes damage, while under-inflated tires can overheat, leading to tread separation or blowouts. Regular checks and adjustments can prevent these dangerous situations.

Fuel Efficiency: Maximizing Your Miles per Gallon

Properly inflated tires reduce rolling resistance, the energy your vehicle needs to move forward. When tires are under-inflated, your vehicle’s engine must work harder to overcome increased rolling resistance, leading to higher fuel consumption.

By maintaining the correct tire pressure, you can improve your vehicle’s fuel efficiency by up to 3%, according to the U.S. Department of Energy. Over time, this translates to significant savings at the pump and a lower environmental impact.

Tire Lifespan: Avoiding Premature Wear

- Even Wear: Tires inflated to the manufacturer’s recommended pressure wear more evenly, ensuring the longest possible lifespan. Under-inflated tires tend to wear excessively on the edges, while over-inflated tires wear down the center tread faster.

- Preventing Early Replacement: Avoiding uneven wear patterns can prevent early tire replacement, saving money and reducing waste. Regular pressure checks and adjustments ensure your tires wear evenly, allowing you to maximize your investment.

Methods for Checking Tire Pressure

Regularly checking your tire pressure ensures your vehicle’s safety, efficiency, and longevity. Here are the primary methods for monitoring tire pressure and some best practices for obtaining the most accurate readings.

Using a Tire Pressure Gauge

Tire pressure gauges come in digital and analog forms, both effective for checking your tires’ pressure. Here’s how to use them:

- Digital Gauge: Turn on the gauge and place its nozzle over the tire’s valve stem. Press firmly to ensure a good seal and prevent air from escaping. The digital display will show the tire’s pressure. These gauges are generally more accurate and easier to read, especially in low-light conditions.

- Analog Gauge (Dial Gauge): Remove the tire’s valve cap, and press the gauge evenly onto the valve stem. The air pressure will push a needle to indicate the pressure on a dial. Ensure the gauge is perpendicular to the valve to avoid air leakage during measurement.

For both types, check the pressure when the tires are cold, as heat from driving can temporarily increase pressure readings. Compare the measured pressure with the manufacturer’s recommended levels, typically found on a sticker inside the driver’s door jamb or in the vehicle’s manual.

Reading Tire Pressure Monitoring System (TPMS) Alerts

Many modern vehicles have a Tire Pressure Monitoring System (TPMS), which alerts drivers when tire pressure is significantly low. Understanding these alerts is crucial:

- Direct TPMS: Provides real-time pressure readings for each tire, often displayed on the vehicle’s dashboard. This system can indicate exactly which tire is under-inflated, allowing for prompt adjustments.

- Indirect TPMS: Uses wheel speed sensors to infer pressure loss through changes in tire rotation speed. While it doesn’t provide precise pressure readings, it will trigger a warning light on the dashboard when a tire’s pressure is low.

Regularly check your vehicle’s dashboard for TPMS alerts and refer to the owner’s manual to understand the specific warnings your vehicle provides.

Best Practices for Checking Tire Pressure

- Check When Tires Are Cold: Tire pressure should be checked when the tires are cold, as driving heats up the tires and increases pressure. For the most accurate reading, check tire pressure in the morning after the car has been parked overnight or at least three hours after driving.

- Frequency: It’s recommended to check your tire pressure at least once a month and before long trips. Tires can lose air over time due to natural permeation and seasonal temperature changes.

- Don’t Forget the Spare: Include your spare tire in your regular checks. A properly inflated spare is just as important in the event of a flat tire.

- Adjust for Load: The vehicle manufacturer recommends adjusting tire pressure for heavy loads. This information can typically be found in the vehicle’s manual.

Recommended Tread Depth and Tire Pressure Levels

Proper tread depth and tire pressure are essential for vehicle safety, performance, and efficiency. Here are the recommended levels for each and how they vary based on vehicle type.

Tread Depth

- Passenger Cars, SUVs, and Light Trucks: The minimum safe tread depth for most passenger vehicles is 2/32 of an inch. This is the legal minimum in many jurisdictions and is a critical threshold for maintaining adequate traction, especially in wet conditions. Some safety advocates recommend replacing tires when they reach 4/32 of an inch of remaining tread depth to improve safety on wet roads.

- Heavy Vehicles: Larger, heavier vehicles such as commercial trucks may have different requirements based on specific regulations and their unique handling characteristics. For example, the Federal Motor Carrier Safety Administration (FMCSA) requires a minimum tread depth of 4/32 of an inch on steer tires and 2/32 of an inch on all other tires.

It’s important to note that different tire types (e.g., winter tires) might also have specific recommendations for optimal performance, often suggesting a deeper tread depth than the minimum legal requirements for enhanced grip in snow and ice conditions.

Tire Pressure

- Manufacturer-Recommended Levels: The ideal tire pressure for your vehicle is specified and designed to ensure optimal safety, handling, and fuel efficiency. This recommended pressure can usually be found on a sticker inside the driver’s door jamb or in the vehicle’s owner’s manual. It’s important to follow these recommendations rather than the maximum pressure listed on the tire sidewall, which indicates the tire’s maximum load-carrying capacity and not the optimal pressure for your vehicle.

- Passenger Cars: Most cars will have a recommended tire pressure range of 30 to 35 psi (pounds per square inch) when cold. However, the exact number can vary based on the vehicle’s weight, performance characteristics, and the tire size.

- SUVs, Light Trucks, and Heavy Vehicles: These vehicles may require different pressures due to their higher load-carrying capabilities and tire specifications. It’s not uncommon for recommended pressures to be higher than those for standard passenger cars, particularly for rear tires in vehicles that carry heavy loads or tow trailers.

Importance of Adhering to Specifications

Maintaining the manufacturer-recommended tire pressure is crucial for several reasons:

- Safety: Correct tire pressure ensures the vehicle has the best possible traction and handling characteristics, reducing the risk of accidents.

- Efficiency: Properly inflated tires reduce rolling resistance, improving fuel economy.

- Tire Longevity: Tires inflated to the correct pressure wear more evenly and are less susceptible to damage, extending their lifespan.

Seasonal and Environmental Considerations

The impact of seasonal changes and environmental conditions on tire tread depth and pressure cannot be overstated.

As temperatures fluctuate and road conditions vary, adjusting your vehicle’s tire maintenance strategy is essential for optimal safety, performance, and durability.

Here’s how to navigate these adjustments:

Adjusting for Weather

- Hot Climates: The air inside your tires can expand in warmer temperatures, leading to higher tire pressure. It’s crucial to check tire pressure regularly to ensure it doesn’t exceed the manufacturer’s recommended maximum. Over-inflated tires can reduce the tire’s contact area with the road, leading to decreased traction and increased wear in the center of the tread. If you live in a consistently hot climate or are entering a warmer season, consider checking your tire pressure more frequently and adjust as necessary to maintain optimal performance.

- Cold Climates: Conversely, tire pressure can drop in colder temperatures as the air inside the tires contracts. This under-inflation can increase tire wear on the edges and reduce fuel efficiency. More importantly, it can negatively affect handling and increase the risk of tire failure. It’s advisable to check your tire pressure regularly during colder months and inflate your tires according to the manufacturer’s recommendations to compensate for this natural decrease in pressure.

Special Conditions

- Snowy Conditions: For those driving in snowy or icy conditions, deeper tread depth is beneficial for improved grip and safety. Winter tires, specifically designed for cold weather, typically feature deeper tread patterns and softer rubber compounds to handle snowy and icy roads better. If you regularly drive in winter conditions, consider switching to winter tires and maintaining a tread depth greater than the standard 2/32 inch minimum to ensure adequate traction.

- Off-Road Conditions: Driving on rough, uneven, or muddy surfaces requires tires with deeper tread for better grip and stability. Off-road tires are designed with larger tread blocks and deeper grooves to navigate these challenging conditions effectively. Adjusting tire pressure lower than usual can increase the tire’s footprint for better traction in off-road conditions. However, it’s important only to decrease pressure when necessary and to re-inflate tires to the recommended levels before returning to standard roads to prevent damage and ensure safety.

Best Practices for Seasonal Adjustments

- Regular Checks: Seasonal changes in temperature can affect tire pressure, so it’s advisable to check your tires at least monthly and adjust as necessary to match the manufacturer’s recommendations.

- Use the Right Tires: Consider seasonal tire changes if you live in an area with extreme weather conditions. Switching between summer and winter tires can significantly improve your vehicle’s handling and safety throughout the year.

- Adjust for Load: When carrying heavy loads or towing, adjust tire pressure to accommodate the increased tire demand, as the manufacturer recommends.