GM’s 5.3L Vortec motor is built on the small block V8 framework, applied to create many LS lineup motors for the Chevrolet Corvette. However, the 5.3L is mainly employed for trucks and SUVs.

5.3L Vortec has a minimum of 9 variations, but they are generally either Generation III or Generation IV V8 small block motors. The main difference between these motors is block construction modifications to ensure more efficient fuel consumption and switch off cylinders if they aren’t necessary for power production. Moreover, the motor was built to all variable timing.

Generation III motors were utilized for Cadillac Escalade, GMC Savana, Sierra, Yukon and Envoy, Chevy Avalanche, Express, Silverado, Tahoe, Trailblazer, SSR, and Suburban, Buick Rainier, plus Isuzu Ascender. In its turn, Generation IV was applicable for the same vehicles (exceptions are Escalade, SSR, Savana, and Express), but was also offered for Chevy Colorado, Saab 9-7x, and Hummer H3.

Its first application, to be exact its LM7 modification, was in a 1999 Chevy Silverado. Then, in 2002, the company presented L59, a flexible fuel variation of LM7.

In 2003, LM4 was released, which is actually a version of LM7 but with an aluminum block. In 2005, the other aluminum block motor, L33, was presented. However, it kept other pistons and cylinder head, contributing to output increase. Those motors of Generation III were released till 2007 when their production was ceased.

Generation IV motors were first manufactured in 2005, and LH6 was a debut version, offering active fuel management.

LY5, LMG plus LC9 motors were presented in 2007 and served as extra variations of Generation IV small block.

GM presented its LH8 version in 2008. Its restyled construction allowed installation in H3 and small trucks. These motors were noted for their good power for big vehicles with small towing demands and great fuel economy compared to similar motors with a small block. Moreover, LH8 turned out to be a very reliable motor.

LM7 5.3L Vortec Specs

| Engine code | GM / Chevy LM7 (Vortec 5300) |

| Layout | Four-stroke, V8 |

| Fuel type | Gasoline (petrol) |

| Production | 1999-2007 |

| Displacement | 5.3 L, (325 cu in) |

| Fuel system | Sequential multi-port fuel injection |

| Power adder | None |

| 5.3 Vortec hp | 273 PS (201 kW; 270 HP) 290 PS (213 kW; 285 HP) 299 PS (220 kW; 295 HP) |

| Torque output | 427 N·m (43.5 kg·m, 314.7 ft·lb) 441 N·m (45.0 kg·m, 325.0 ft·lb) 454 N·m (46.3 kg·m; 335.0 ft·lb) |

| Firing order | 1-8-7-2-6-5-4-3 |

| Compression ratio | 9.5:1 |

| 5.3 Vortec Engine Oil Capacity | 6 quarts (5.7 liters) |

| Dimensions (L x W x H): | – |

| Weight | – |

LM7 motor achieved an output of 270 hp with a 315 lb/ft torque. And before Generation III motors were stooped to be produced, L33, which was considered a high productivity variation, demonstrated the power of 310 hp with torque of 336 lb/ft.

Motors of Generation IV showed different output results, but the maximal power equaled 320 hp and torque of 335 lb/ft. Both Generation III and IV engines feature aluminum alloy heads with blocks of various materials, depending on the employment.

Both generations kept the same displacement of 5.328 liters (325.1 cu in), with a bore of 3.78 inches and a stroke of 3.622 inches.

Head And Block Design

| Casting Numbers | 12567392, 12567393, 12551358 |

| Material | Iron |

| Displacement | 5.3L / 325 c.i.d. |

| Bore Dia. | 3.780 in. |

| Stroke | 3.622 in. |

| Deck Height | 9.230-9.240 in. |

| Bore Spacing | 4.400 in. |

| Thrust Bearing Location | #3 Main |

| Main Cap Style | 6-Bolt |

| Main Housing Bore Dia. | 2.751 in. |

| Cam Housing Bore Dia.(1999-2003) | Bore 1/5 = 2.326, Bore 2/4 = 2.317, Bore 3 = 2.307 |

| Cam Housing Bore Dia.(2003-07) | Bore 1/5 = 2.346, Bore 2/4 = 2.326, Bore 3 = 2.307 |

| Cam-to-Crank Centerline | 4.914 in. |

| LM7 Camshaft Specs | ||

|---|---|---|

| Years | 1999 | 2000-2006 |

| Duration @ .050 in. (int./exh.) | 191°/190° | 191°/190° |

| Valve Lift (int./exh.) | 0.457 in./0.466 in. | 0.457 in./0.466 in. |

| Lobe Separation Angle | 115.5° | 114° |

| Cam Gear Attachment | 3-Bolt | 3-Bolt |

| LM7 Throttle Body, Fuel Injector Specs & More | |

|---|---|

| Intake Manifold | Truck Style |

| Throttle Body | 78mm, 3-Bolt |

| Throttle Control (1999-2002) | Throttle Cable |

| Throttle Control (2003-04) | Electronic, Drive-by-Wire (most models) |

| Fuel Injector Flow (1999) | 21.8 lbs./hr. |

| Fuel Injector Flow (2000) | 24.8 lbs./hr. |

| Fuel Injector Flow (2001-07) | 25.2 lbs./hr. |

| Fuel Injector Length Between O-Rings | 1.9 in. |

| Fuel Injector Connector | Mini-Delphi / Multec2 |

| PCM | Warren |

| Crankshaft Reluctor Ring | 24x |

| Camshaft Sensor Location | Rear Mount, 1x on cam |

| Oil Pan | Deep Rear Sump |

| Oil Pump | Standard Volume |

Generation III’s LM7 and L59 kept cast iron blocks, whereas LM4 and L33 featured aluminum blocks. LY5 and LMG of Generation IV were equipped with cast iron blocks, whereas LH6, LH8, LH9, plus LC9 went with aluminum blocks.

All the mentioned above motors employed overhead valve design with one intake and 1 exhaust valve per cylinder. A classic camshaft operated valves in block connecting rod systems. Generation IV motors have more options, comprising variable timing.

Applications And VIN Codes

| VIN 8th Digit | Year | Make | Model |

| T | 1999-2007 | Chevrolet | Silverado 1500 |

| T | 1999-2007 | GMC | Sierra 1500 |

| T | 1999-2006 | Chevrolet | Tahoe |

| T | 1999-2006 | Chevrolet | Suburban 1500 |

| T | 1999-2006 | GMC | Yukon |

| T | 1999-2006 | GMC | Yukon XL 1500 |

| T | 2002-2005 | Cadillac | Escalade (2WD) |

| T | 2002-2006 | Chevrolet | Avalanche |

| T | 2003-2007 | Chevrolet | Express |

| T | 2003-2007 | GMC | Savana |

Is a 5.3 Vortec An LS Motor?

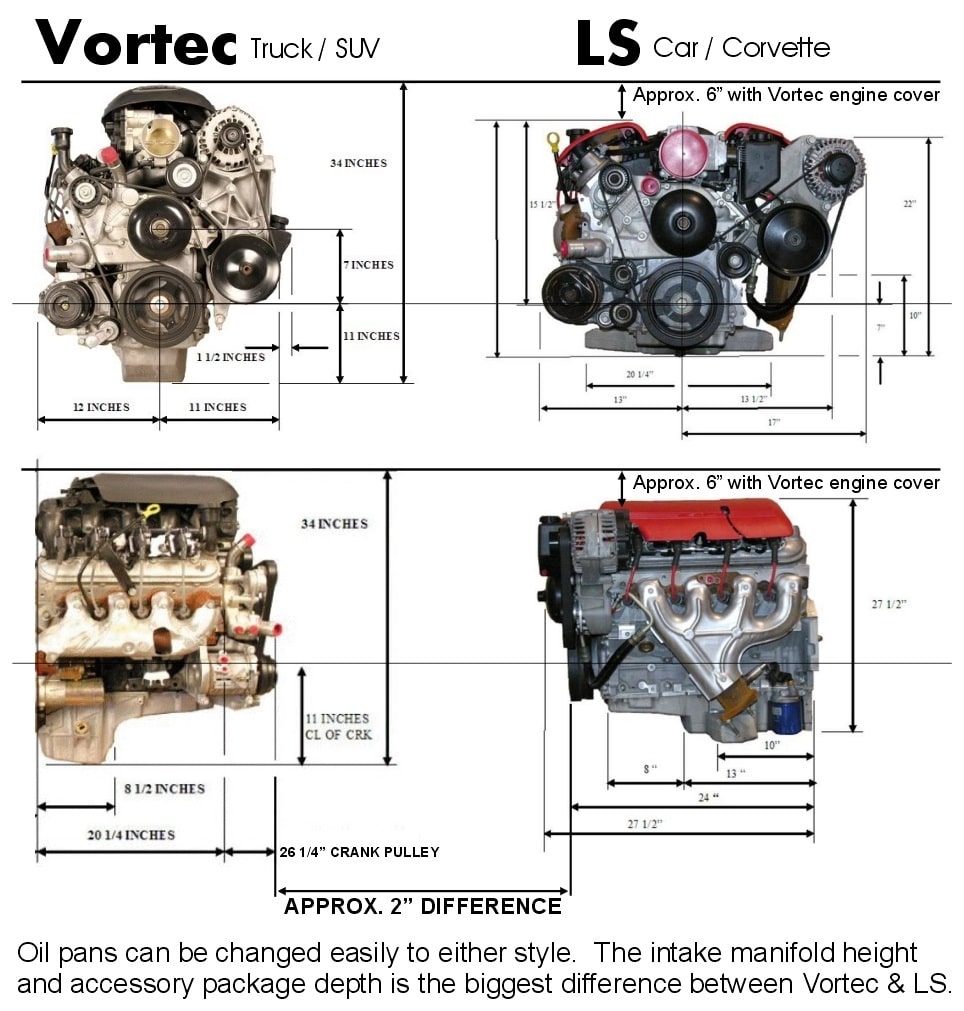

People often make the mistake of believing that LS motors and Vortec motors are the same. Indeed Vortec engines are “LS” based, but still, Vortec motors are designed for trucks, and LS motors are for cars.

Common Bolt-On Updates for LM7 Motors

Truck owners often deal with upgrading cold air intake plus aftermarket exhaust. Consequently, motors start sounding so powerful that it’s impossible to resist the temptation of driving faster.

Trucks are often provided with mechanical fans, which can destabilize a motor’s output. The solution is to apply an electric fan kit. You can easily change all those details yourself, but note that the tune will remain non-optimized.

It’s advisable to turn to a chassis dyno tuner or a computer programmer. They may assist you in attuning the ECM and making the engine work smoothly whether you use low-octane or high-quality fuel.

Offset points can be raised, leading to an easier adjustment of a larger cam and injectors in the future. Additionally, tuning will be more efficient if you mount a colder thermostat.

LM7 5.3 Vortec Problems And Reliability

The 5.3L Vortec is regarded as a very sturdy engine, with most units expected to endure for 200k-300k miles before needing to be replaced. I have a 2002 Suburban with the LM7 engine in it, and it’s still running strong at 220k miles with no major issues. It has been without a doubt the cheapest automobile I’ve ever owned when it comes to maintenance and repair costs.

On these cars, the engine blocks are almost impenetrable. You’ll have to replace some basic components during the car’s life, such as the water pump, plugs and coils, and some gaskets and hoses, but in general, the engine block is quite durable and rarely causes issues.

- Spark plug failure from carbon build-up

- Excessive oil consumption

- Cracked cylinder head (not super common)

- Intake manifold and gasket

- Fuel pressure regulator failure

Is The LM7 a Good Engine?

The Chevrolet LM7 Vortec engine is a good engine. It’s affordable, reliable, and has plenty of aftermarket support if you’re looking to add some power. This engine is also popular among builders and tuners due to its durability and performance. If you’re looking for an engine that will last you long and provide plenty of power, the Chevrolet LM7 Vortec engine is a great choice.

How Long Do LM7 Engines Last?

Three is one of the most dependable engines on the market, with a lifespan ranging from 200,000 to 300,000 miles. In fact, it can last even more, up to 400,000 miles if properly maintained.

To Sum It Up

Noted for its great lifespan and reliability, 5.3L Vortec has become more and more popular. It’s generally applied for trucks and large SUVs, the owners of which never complain of its durability.

Clearly, its output differs from one of LS motors, which is closely coordinated. 5.3L Vortec is more focused on weight carrying than LS engines built for SUVs plus trucks. Mainly, these motors are equipped with cast iron blocks (especially the ones for large trucks). Nevertheless, some versions go with aluminum heads and blocks.

Dan question is the 5.3 motor in a 2002 Silverado the same setup in a 2012 Silverado if I was going to swap out I have a good 5.3 and the 2012 has some high mileage needs rebuilding