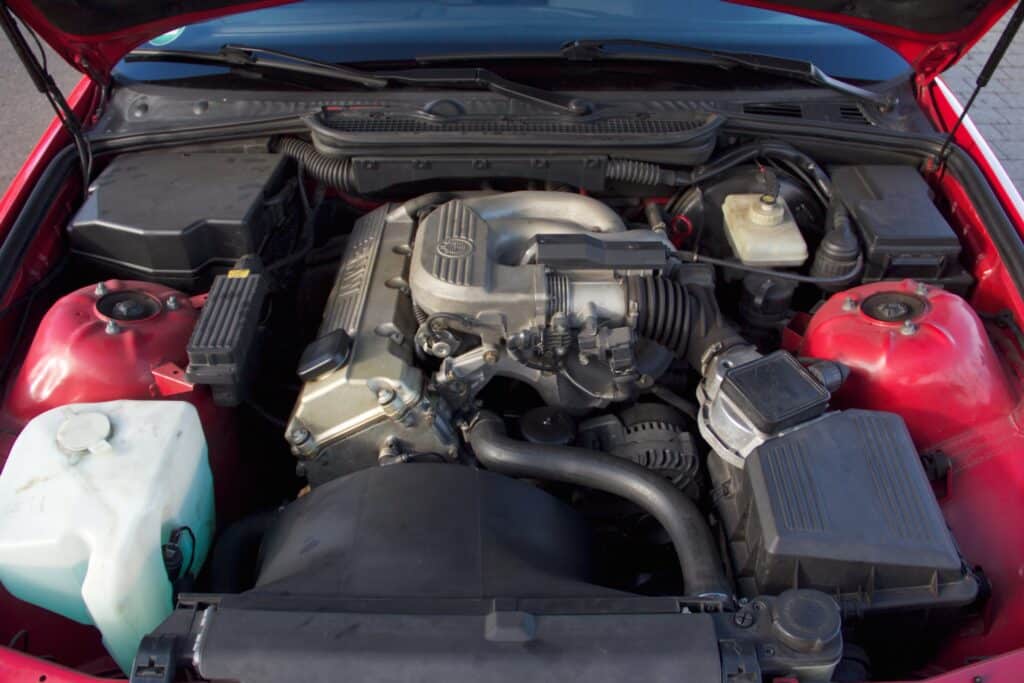

The BMW S54B32 represents a pinnacle of engineering excellence in the realm of high-performance engines. As the heart of some of the most iconic BMW M models, the S54B32 is a naturally aspirated, straight-six engine revered for its high-revving capabilities and thrilling power delivery. Introduced in the late 1990s, this powerplant succeeded the famous S50B32 and quickly became a legend in automotive circles.

This engine boasts a displacement of 3.2 liters and utilizes a DOHC (double overhead camshaft) layout with four valves per cylinder. With an emphasis on achieving a high power output without forced induction, BMW engineered the S54B32 to provide an exhilarating driving experience that is synonymous with the M division’s motorsport heritage

Its use of advanced materials and technology, such as individual throttle bodies, continuously variable Vanos valve timing on both intake and exhaust cams, and a sophisticated Siemens MSS54 engine control unit, solidifies its status as a marvel of its era.

The legacy of the S54B32 is indelibly etched into the annals of automotive history through its application in vehicles that have become cult classics. This engine served as the powerhouse for the E46 M3, a vehicle often lauded as one of its generation’s best driver’s cars.

It also powered the more track-focused M3 CSL, Z3 M Coupe, and Roadster, along with the Z4 M Coupe and Roadster, vehicles that have amassed a passionate following due to their dynamic capabilities and engine performance.

The S54B32’s impact extends beyond just the cars it powered; it set a benchmark for what enthusiasts expect from a performance engine. Its ability to deliver smooth power from idle to the redline and its characteristic sonorous exhaust note, create a sensory experience that is as pleasurable as it is unforgettable.

Moreover, the engine’s tunability and robustness have made it a favorite among tuners and racers seeking to extract even more performance for both street and track applications.

The BMW S54B32 isn’t merely an engine; it represents a bygone era when natural aspiration and driver engagement reigned supreme. It embodies BMW’s unwavering commitment to uncompromising performance, and it remains a source of admiration among automotive enthusiasts worldwide.

S54B32 Engine Specs

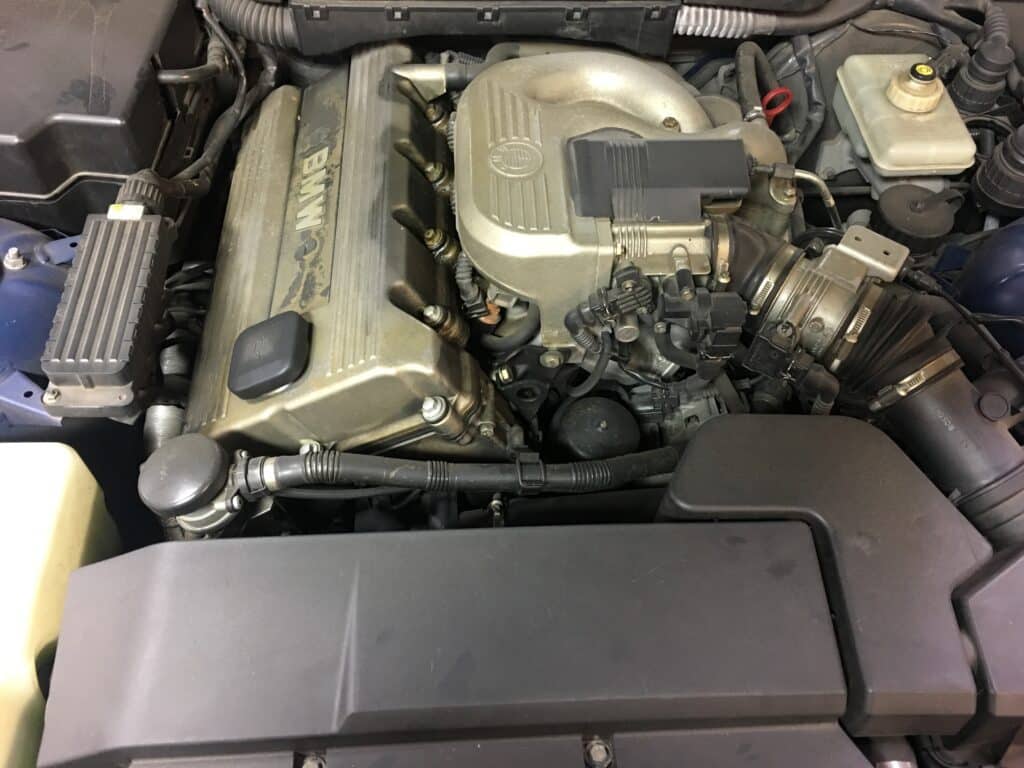

The BMW S54B32 engine is an iconic powerplant that is well-known for its performance and engineering. Below, we delve into the basic specifications, performance metrics, and the engine’s design and construction.

The S54B32 is a 3.2-liter (3246 cc) inline-six engine with a cast iron block and aluminum cylinder head. This naturally aspirated unit employs a dual overhead camshaft (DOHC) design and is equipped with BMW’s VANOS (Variable Nockenwellen Steuerung) variable valve timing on both the intake and exhaust camshafts.

The specifics of the engine are impressive and are tabulated below:

| Specification | Detail |

|---|---|

| Displacement | 3.2 L (3246 cc) |

| Engine Type | Inline-6 |

| Block Material | Cast Iron |

| Cylinder Head Material | Aluminum |

| Valvetrain | DOHC, 4 Valves per Cylinder |

| Compression Ratio | 11.5:1 |

| Bore x Stroke | 87 mm x 91 mm |

| Max RPM | 8000 RPM |

| Fuel Delivery | Sequential Multi-Port Injection |

| Induction | Natural Aspiration |

| Engine Management | Siemens MSS54 |

| Valve Timing System | BMW VANOS (Variable Valve Timing) |

The S54B32 engine is highly regarded for its remarkable horsepower and torque outputs, contributing to the exhilarating performance of the vehicles it propels. The engine produces a peak horsepower of approximately 333 hp (248 kW) at 7900 rpm and a maximum torque of 262 lb-ft (355 Nm) at 4900 rpm. These figures enable the cars equipped with this engine to deliver rapid acceleration and responsive power delivery throughout the rev range.

The design and construction of the S54B32 engine reflect BMW’s commitment to performance and durability. The engine’s cylinder head is made from aluminum, which contributes to a reduction in overall weight and improves thermal efficiency. Using individual throttle bodies for each cylinder ensures precise control of the air entering the engine, resulting in sharper throttle response and increased power output.

Internally, the engine features forged steel crankshaft and connecting rods coupled with high-strength pistons to withstand the stresses of high-speed operation. The engine also incorporates an advanced cooling system designed to maintain optimal operating temperatures, even under extreme driving conditions.

The S54B32’s design is completed with a sophisticated engine management system, the Siemens MSS54, which precisely controls fuel injection, ignition timing, and variable valve timing to optimize performance and efficiency.

The culmination of these design elements makes the S54B32 a standout engine, renowned for its high-revving nature, robustness, and ability to deliver a visceral driving experience that automotive enthusiasts and professionals alike highly sought after.

S54B32 Engine Reliability and Longevity

The BMW S54B32 engine is synonymous with durability and performance. Engineered to withstand the rigors of high-performance driving, it has carved out a reputation for being a robust and dependable engine when properly maintained. The extensive use of high-quality materials and precise engineering contributes to its longevity.

For instance, using a cast iron block provides exceptional strength, while the aluminum cylinder head helps with efficient heat dissipation, both critical factors for enduring the high-rev stresses that this engine was designed to handle.

Common Issues and Engine Problems

Despite its robust design, the S54B32 engine is not without its issues. One of the most well-documented problems is related to the VANOS system, BMW’s variable valve timing mechanism. Over time, seals within the VANOS unit can deteriorate, leading to loss of performance and increased fuel consumption.

Another area of concern is the rod bearings, which can wear prematurely if the engine is consistently run at high RPMs without proper lubrication or if oil changes are not performed at the recommended intervals.

The engine’s cooling system, particularly the water pump and thermostat, can also become points of failure, potentially leading to overheating if not addressed promptly.

Additionally, the S54B32’s high-performance nature means it’s sensitive to the quality of its consumables like oil, coolant, and fuel, requiring strict adherence to recommended specifications for optimal performance and longevity.

Maintenance Tips for Enhanced Reliability

Regular and thorough maintenance is key to maximizing the reliability of the S54B32 engine. Here are some essential tips:

- Oil Changes: Use only the specified grade of oil and adhere to a strict oil change schedule. Due to the high-performance nature of the engine, shorter oil change intervals than recommended by the manufacturer can prevent premature wear.

- VANOS System: Regularly inspect the VANOS system for signs of wear or failure. Replacing the seals and solenoids at the first sign of trouble can prevent more significant issues.

- Rod Bearings: Monitor the condition of the rod bearings and consider more frequent inspection intervals if the vehicle is used for high-performance driving.

- Cooling System: Regularly inspect and maintain the cooling system components, including the radiator, water pump, and thermostat, to prevent overheating.

- Ignition System: Keep the ignition system, including spark plugs and coil packs, in top condition to ensure optimal engine performance and efficiency.

- Engine Management: Use a diagnostic scanner to check for any fault codes that could indicate potential issues with the engine management system, which can prevent minor problems from becoming major.

Adhering to a rigorous maintenance schedule and promptly addressing issues extends the life of the S54B32 and ensures it continues to perform at the high level expected of a BMW M engine.

Regular checks by a professional familiar with the intricacies of this specific engine can make a world of difference in preserving its performance and reliability.

S54B32 Engine Problems and Troubleshooting

The Variable Nockenwellen Steuerung (VANOS) system is integral to the S54B32 engine and is responsible for varying valve timing for optimal engine performance and efficiency. However, VANOS components are prone to wear and failure, often indicated by a rough idle, loss of power or a rattling noise from the front of the engine. Solenoid failure and seal degradation can lead to improper timing adjustments and reduced engine responsiveness.

Troubleshooting VANOS issues should start with a diagnostic scan to identify any fault codes. A comprehensive check includes examining solenoids and actuators for electrical faults and inspecting seals and gaskets for deterioration. In some cases, a complete VANOS rebuild may be necessary to replace all seals, gaskets, and worn mechanical components.

Rod Bearing Wear and Replacement

Rod bearings in the S54B32 are known to be a weak point, particularly in engines subjected to high loads and extended high-rev operation. These bearings are critical, connecting the pistons to the crankshaft and ensuring smooth rotation. When they wear out, the engine may emit a knocking sound, especially under load, or in severe cases, fail, leading to catastrophic engine damage.

Regular oil analysis can be a key preventive measure to troubleshoot rod bearing wear, detecting metallic particles that indicate early wear. If rod-bearing issues are suspected, it is imperative to address them immediately. The process of replacing rod bearings is labor-intensive and requires a skilled mechanic.

It involves removing the engine’s oil pan and lower crankcase to access the bearings, assessing the crankshaft for damage, and installing new, high-quality bearings.

Cooling System Issues and Overheating

The cooling system in an S54B32 engine is robust but can be the Achilles’ heel if maintenance is neglected. Issues like a failed water pump, clogged radiator, or a malfunctioning thermostat can lead to overheating, which is particularly detrimental to a high-performance engine. Overheating can cause head gasket failure, warped cylinder heads, or even a cracked engine block.

Troubleshooting cooling system problems begin with checking for leaks, which can be external or internal and may involve inspecting hoses, the radiator, and the water pump. The thermostat should be tested for proper operation, as a stuck thermostat can prevent coolant from circulating.

Overheating may also stem from a failing fan clutch or electric fan, which are crucial for maintaining proper airflow through the radiator, especially during idle or low-speed conditions.

In the event of an overheating engine, it is crucial to shut down the engine immediately to avoid further damage. Once cooled, the system should be pressure tested to identify any leaks. The coolant should be examined for signs of oil, which could indicate a head gasket leak. It’s also advisable to flush the cooling system periodically to prevent corrosion and buildup, which can impede coolant flow.

Regular maintenance, including timely replacement of the water pump and thermostat, can preempt many of these issues. Ensuring the cooling system is filled with the correct mixture of antifreeze and water is also vital, as is ensuring the system is properly bled to remove air pockets that can impair cooling efficiency.

Oil Specifications for the S54B32 Engine

For the S54B32 engine, BMW recommends using synthetic oil that meets its Longlife-01 specification. The preferred viscosity rating is 10W-60, which is particularly suited for this high-revving engine’s high-temperature and high-shear environment.

This specific viscosity ensures adequate lubrication during cold starts and provides a stable oil film at high temperatures, which is crucial for the engine’s performance and protection.

Oil Capacity and Change Intervals

The S54B32 has an oil capacity of approximately 6.5 liters, including the filter. BMW’s initial service interval recommendation for oil changes was every 15,000 miles.

However, many enthusiasts and experts advocate for more frequent oil changes, particularly for engines that see regular spirited driving or track use. A conservative interval of 7,500 miles, or annually, whichever comes first, is often recommended to ensure optimal engine health and performance.

Effects of Oil Choice on Engine Health

The choice of oil can significantly affect the S54B32’s engine health. The high-performance nature of this engine means it can be particularly sensitive to the oil’s protective qualities.

Using oil with the correct viscosity is critical for maintaining the strength of the oil film between engine components, thereby reducing wear, especially on critical components such as rod bearings.

Moreover, the quality of the oil influences the engine’s VANOS system operation, with poor-quality oil potentially leading to sluggish performance and premature wear of the system’s intricate components.

Furthermore, high-quality synthetic oils can better resist thermal breakdown, maintain stability under extreme conditions, and provide efficient lubrication to the engine’s tight tolerances.

S54B32 Fuel Consumption and Efficiency

The BMW S54B32 engine, while engineered for high performance, does not prioritize fuel efficiency as its foremost objective. In real-world conditions, the average fuel economy for vehicles powered by the S54B32 engine can vary significantly.

Generally, owners can expect an average of around 16-20 miles per gallon (MPG) in mixed driving conditions. This figure can drop into the lower teens when the engine is subjected to more aggressive driving, particularly on track days or when exploiting the engine’s full performance potential.

Factors Influencing Fuel Consumption

Several factors can influence the fuel consumption of the S54B32 engine. Driving habits are at the forefront; spirited driving that involves high RPMs will inevitably lead to increased fuel consumption. The engine’s health also plays a role; a well-maintained engine with clean filters and fresh spark plugs will operate more efficiently than one that has been neglected.

Additionally, using vehicle accessories such as air conditioning and the vehicle’s weight, including passengers and cargo, can also impact fuel efficiency.

Tips for Improving Fuel Efficiency

To improve the fuel efficiency of the S54B32 engine, consider the following tips:

- Regular Maintenance: Keep up with regular maintenance, including oil changes, air filter replacements, and spark plug inspections to ensure the engine runs efficiently.

- Conservative Driving: Adopt a more conservative driving style, with smoother acceleration and using the engine’s torque to maintain speed rather than constant high RPMs.

- Tire Pressure: Ensure tires are inflated to the correct pressure, as under-inflated tires can cause the engine to work harder, thus consuming more fuel.

- Weight Reduction: Remove unnecessary weight from the vehicle to reduce the engine load.

- Use of High-Quality Fuel: Use the recommended octane fuel to keep the engine’s performance optimal, as lower octane fuels can affect combustion efficiency and, therefore, fuel economy.

Driving a BMW with an S54B32 engine can be exhilarating, but it doesn’t have to drain your wallet or harm the environment. With some simple techniques, you can make this powerful engine more fuel-efficient without giving up the responsive performance BMW drivers love. Focus on smooth acceleration and braking, avoiding jackrabbit starts and hard stops.

Keep speeds moderate on the highway and use cruise control when possible. Regular maintenance like oil changes, air filter replacement, and spark plug swaps optimizes combustion. And don’t haul unneeded cargo or let the gas tank run near empty, which reduces mileage.

Applying fuel-smart driving habits lets you enjoy the thrill of your BMW’s high-revving straight six while maximizing mileage. The result? More miles per gallon and fewer trips to the pump.

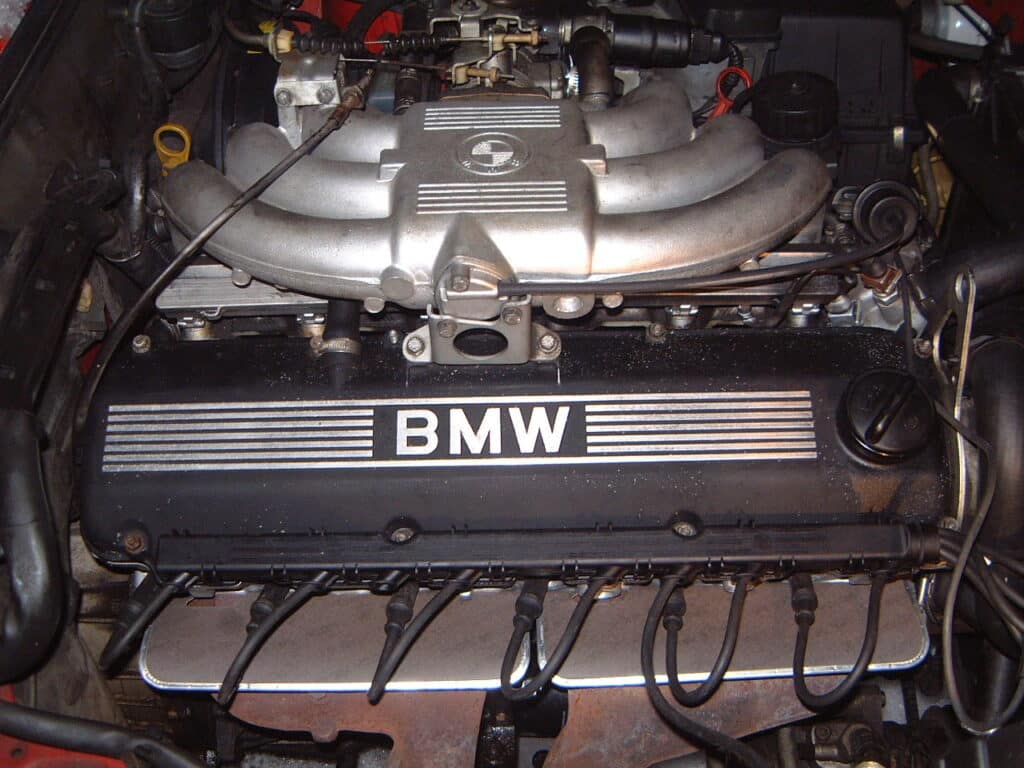

S54B32 Engine Firing Order and Ignition

The firing order of an engine is the specific sequence in which each cylinder receives a spark, causing the fuel-air mixture to ignite and drive the piston down. For the BMW S54B32 engine, the firing order is 1-5-3-6-2-4.

This sequence is meticulously engineered to balance the engine’s operation, minimizing vibration and maximizing smoothness and power output. The order plays a critical role in the engine’s performance, contributing to its legendary smoothness and the linear power delivery for which it is renowned.

The S54B32’s ignition system is a key player in the engine’s performance and reliability. It comprises several components, including high-energy ignition coils, spark plugs, and a sophisticated engine control unit (ECU). The ignition coils convert the battery’s low voltage to the high voltage needed to create a spark at the spark plugs.

This spark ignites the compressed air-fuel mixture within the cylinders, a process meticulously timed by the ECU for optimal performance and efficiency.

Timing and Spark Plug Gapping

Timing is crucial to the ignition system’s function, with the ECU ensuring that the spark occurs precisely at the right combustion moment. If the timing is off, the engine can run poorly, lose power, or even suffer damage. Similarly, spark plug gapping – the distance between the ground and central electrodes – is critical. For the S54B32, the recommended gap is typically between 0.7 to 0.8 mm.

This gap size is crucial because it affects the spark’s strength and combustion efficiency. Too wide of a gap can lead to misfires and poor performance, while too narrow of a gap can cause a weak spark, leading to incomplete combustion and reduced efficiency.

Proper ignition system maintenance, including regular checks of the spark plug gap and timely replacement of worn components, is essential. By ensuring that these elements are in good working order, the S54B32 can continue to deliver the high-revving performance that BMW’s M Division engines are celebrated for.

S54B32 Engine Timing System

The S54B32 engine utilizes a timing chain rather than a belt. A timing chain is a robust metal chain that, unlike a rubber belt, is designed to last the engine’s life under normal conditions. The chain ensures synchronized rotation of the crankshaft and camshaft, meaning that the engine’s valves open and close correctly during each cylinder’s intake and exhaust strokes. The S54’s timing chain is a critical component, and its durability contributes significantly to the engine’s overall reliability and longevity.

Timing Chain vs. Belt

Timing chains and belts serve the same purpose but are fundamentally different in their durability and maintenance requirements. Chains are made of metal and are more durable, typically lasting longer than timing belts, which are made from rubber and can wear out or break after a certain number of miles.

A significant advantage of the S54’s timing chain is that it is generally maintenance-free, whereas timing belts require regular replacement intervals. However, chains are not infallible and can stretch or wear over time, particularly if the engine is improperly maintained.

Timing System Maintenance

Though the timing chain in an S54B32 engine is designed to be maintenance-free, it operates in a harsh environment and depends on proper lubrication to function correctly. Regular oil changes with the correct oil specification are vital to keep the timing chain lubricated and reduce the chances of wear or failure.

Additionally, the tensioner and guide rails – components that keep the chain taut and in place – can wear out and should be inspected periodically, especially during major engine overhauls or if any irregular noise arises from the timing chain area.

While the S54’s timing chain system is robust, it’s essential not to overlook other related components. For example, the VANOS system, which adjusts the timing of the valves, relies on the chain for its operation. If the chain stretches or the tensioners fail, it can lead to VANOS system malfunctions and reduced engine performance.

Interference Design in the S54B32 Engine

An interference engine is one in which the path of the piston overlaps with the open valves during the timing cycle. This design in the BMW S54B32 engine allows for higher compression ratios and improved performance, as it permits larger valves and more aggressive camshaft profiles. This design approach is typical in high-performance engines with optimized efficiency and power output.

The difference between non-interference and interference engines lies in the potential for contact between pistons and valves. In a non-interference engine, there is enough clearance between these components to avoid collision, even if the timing belt or chain fails.

This means that a failure of the timing mechanism is less likely to cause significant engine damage. Conversely, in an interference engine, such a failure often results in contact between pistons and valves, leading to severe engine damage and costly repairs.

The interference design of the S54B32 means that maintaining the timing chain and related components is critical. Should the chain fail, the result could be bent valves, damaged pistons, and potentially catastrophic engine damage. This underscores the importance of preventive maintenance and timely replacement of components showing signs of wear.

However, the benefits of the interference design for an engine like the S54B32 are substantial. The tighter clearances allow for better compression, leading to more power and immediate response, a defining characteristic of M Division engines. The design also encourages efficient combustion, contributing to the engine’s exceptional power output relative to its displacement.

Owners of vehicles equipped with the S54B32 engine should be mindful of the interference nature of their engine and ensure that their maintenance schedule accounts for the health of the timing chain system. While the risk of failure is inherent to the interference design, with proper care, the S54B32 can deliver high performance and driving pleasure without undue concern for the potential pitfalls associated with this engine architecture.

S54B32 Cooling System

The cooling system of the BMW S54B32 engine plays a crucial role in maintaining optimal operating temperatures and preventing overheating. For this engine, BMW specifies a coolant that meets its own antifreeze specifications.

This coolant is a 50/50 mix of antifreeze and distilled water, providing freeze protection, boiling point elevation, and corrosion inhibition. It’s vital to use the correct type of coolant to ensure proper thermal regulation and to prevent corrosion and buildup within the cooling system.

Maintaining the S54B32’s cooling system is essential for engine longevity. The radiator should be kept clean, with the fins clear of debris that can impede airflow and reduce cooling efficiency. Coolant levels should be checked regularly, and the system should be flushed and refilled with fresh coolant according to BMW’s recommended schedule, usually every two years.

During maintenance, inspecting hoses, the radiator cap, and the water pump for signs of wear or leakage is also important. The thermostat, which regulates the coolant flow between the engine and the radiator, should also be tested and replaced if it fails to open and close at the designated temperatures.

Signs of Cooling System Problems

Several indicators can signal cooling system issues in the S54B32 engine. If the engine temperature gauge readings are rising or if the temperature warning light on the dashboard is illuminated, it means there is a potential overheating issue. Physical signs of a problem include coolant leaks under the car, steam or a hot smell coming from the engine bay, and unusual noises from the water pump area indicating bearing failure or impeller degradation.

If the heater stops working or if the cabin takes a long time to warm up, this could also indicate a cooling system malfunction, such as a clogged heater core or a failing thermostat.

Any signs of cooling system distress should be addressed promptly to avoid overheating, which can lead to serious engine damage. Regular maintenance, monitoring of the engine’s temperature, and immediate attention to any irregularities are the best defenses against cooling system problems.

Keeping the cooling system in peak condition ensures that the S54B32 engine runs efficiently and continues to deliver the performance expected from BMW’s high-performance powerplants.

Air Intake System

The air intake system of the S54B32 engine is a key contributor to its performance, and at the heart of this system lies the air filter. For this engine, BMW recommends a high-quality, high-flow air filter that meets OEM specifications.

The filter is designed to provide an optimal balance between air flow and filtration, ensuring that the engine breathes clean air without sacrificing performance. It’s important to use a filter that fits precisely, as a proper seal is necessary to prevent unfiltered air from entering the engine.

Importance of Air Filter Maintenance

Regular maintenance of the air filter is critical for the health and efficiency of the S54B32 engine. A clean air filter ensures maximum air flow, which is crucial for maintaining the engine’s power output and fuel efficiency.

Conversely, a dirty or clogged air filter can restrict air flow, leading to reduced performance, higher fuel consumption, and an increased risk of engine wear due to contaminants entering the combustion chamber.

BMW typically recommends inspecting the air filter at every oil change and replacing it as needed, which is generally every 30,000 to 45,000 miles under normal driving conditions.

Upgrades and Performance Enhancements

For those looking to enhance the performance of their S54B32, upgrading the air intake system can be an effective step. Performance air filters and intake systems are available that provide increased air flow and improved filtration. Some enthusiasts opt for cold air intake systems that draw in air from outside the engine bay, which can be cooler and denser, potentially leading to a slight increase in power.

Moreover, the addition of a performance intake system can also alter the engine’s sound, giving a more pronounced and aggressive intake note that many performance drivers appreciate.

However, it’s crucial to choose reputable brands that provide components designed specifically for the S54B32 to ensure compatibility and avoid any negative impacts on the engine’s operation. With the right upgrade, the air intake system can contribute to both the driving experience and the overall performance of the S54B32 engine.

Performance Upgrades for the S54B32 Engine

The BMW S54B32 engine, while robust in its stock form, is a favorite canvas for enthusiasts seeking to enhance its performance. Popular upgrades include ECU tuning, which can recalibrate the engine for higher power output and torque while maintaining drivability. Performance exhaust systems are also favored for reducing backpressure and improving exhaust flow, resulting in a more responsive throttle and a more engaging exhaust note.

Intake systems can be upgraded to cold air intakes that provide a denser and cooler air charge, potentially increasing horsepower. Camshafts with higher lift and longer duration can also be installed to optimize valve timing for better air-fuel mixture and exhaust gases flow, further improving performance.

For those looking to maximize power, forced induction systems like superchargers or turbochargers can be significant but complex upgrades. These modifications can dramatically increase power output but will also have a profound effect on the engine’s dynamics and reliability if not done correctly.

Legal and Environmental Considerations

Performance modifications can also have legal and environmental implications. In many regions, there are strict emissions regulations that modified vehicles must still comply with. Before undertaking any engine modifications, it’s important to check local laws to ensure that the vehicle will remain street-legal.

In addition, there’s an environmental impact to consider; modifications that increase power often do so at the cost of higher fuel consumption and emissions.

In summary, while there are numerous options for upgrading the performance of the S54B32 engine, these should be balanced with considerations of warranty, reliability, legality, and environmental impact.

A thoughtful selection of upgrades, professional installation, and tuning, along with an understanding of the potential trade-offs, are key to enhancing the performance of this legendary engine without compromising its innate qualities.

FAQs

A. Is the S54B32 engine prone to any specific failures?

The S54B32 is known for its high performance, but like any engine, it has its quirks. Specific issues that have been reported include VANOS system failures, rod bearing wear, and occasional problems with the cooling system, such as water pump failure. Regular maintenance and early detection through noise or performance changes can prevent most of these from becoming major problems.

What is the ideal service interval for the S54B32 engine?

BMW originally recommended service intervals of 15,000 miles, but many enthusiasts and professionals suggest more frequent oil changes, every 7,500 miles or annually, to maintain engine health, especially if the car is used for performance driving. Regular checks on the cooling system, VANOS, and other critical components should also be part of the service routine.

Can the S54B32 engine’s power output be safely increased?

Yes, the S54B32’s power output can be safely increased with the right modifications, such as ECU tuning, intake and exhaust upgrades, or even forced induction systems.

However, these modifications should be done professionally, with consideration to the additional strain on the engine and drivetrain components. Keeping the engine well-maintained and not exceeding the limits of its design are crucial for safe power increases.

What are the best practices for ensuring the longevity of the S54B32 engine?

The key to longevity for the S54B32 engine is diligent maintenance. This includes regular oil changes with the correct oil type, keeping the cooling system in good order, ensuring the VANOS system is functioning correctly, and addressing any issues as soon as they arise.

Additionally, driving the car regularly but not always pushing it to its limits can also help extend the engine’s life.

How does the S54B32 compare to other BMW engines in terms of performance?

The S54B32 is often hailed as one of the best naturally aspirated engines produced by BMW, especially within the M Division. It is known for its high-revving nature, delivering power smoothly across a wide RPM range.

When compared to other BMW engines, especially of its time, it stands out for its impressive horsepower per liter, immediate throttle response, and overall driving dynamics.

While newer engines may benefit from turbocharging for increased power and efficiency, the S54B32 remains a benchmark for purists who prefer the response and character of a naturally aspirated engine.